Custom LSR Overmolding for MIM Metal Parts | Metal-Silicone Insert Molding Manufacturer

Item specifics

- Product name

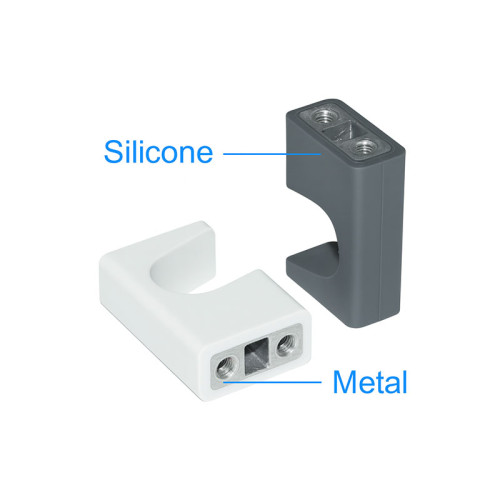

- Custom LSR Overmolding for MIM Metal Parts

- Waterproof grade

- IP68

- Product Material

- Metal + liquid silicone

- Applications

- Automotive Industry

- Product process

- LSR & Metal Insert Molding

Review

Description

Product Overview

Silicone overmolded metal components are produced by bonding stainless steel or alloy inserts with liquid silicone rubber (LSR) through precision injection molding. This hybrid structure delivers high mechanical strength, soft-touch protection, vibration damping, sealing performance, and long-term durability.

At SiliconePlus, we specialize in LSR overmolding and metal insert molding for industrial, medical, electronics, and smart device applications. Our advanced LSR systems ensure strong bonding, tight tolerances, and highly repeatable quality for demanding OEM/ODM projects.

Key Benefits

1. Strong Silicone–Metal Bonding

Surface treatment + high-flow LSR ensures permanent chemical adhesion

No delamination, peeling, or cracking even under long-term stress

2. Precision Injection Molding

Dimensional tolerance up to ±0.02 mm

Suitable for complex geometries, deep grooves, thin-walled parts, and custom inserts

3. Excellent Temperature & Chemical Resistance

Operating temperature: –40°C to 200°C

Resistant to oils, chemicals, aging, oxidation, and environmental stress

4. Safe and Certified Materials

Medical-grade, food-grade, or industrial-grade LSR available

Compliant with ROHS, REACH, FDA, LFGB, UL requirements

5. Wide Application Range

Medical device components

Electronic connectors & protective housings

Industrial damping parts

Precision clamps & handles

Waterproof and sealing structures

Why Choose SiliconePlus

✔ 15+ Years of Silicone Manufacturing Expertise

Deep experience in LSR, compression molding, insert molding, and multi-material solutions.

✔ In-House Mold Center & Automated LSR Workshops

Rapid DFM review, prototype tooling, and stable mass production.

✔ International Quality Standards

ISO 9001 and ISO 13485 certified for medical-grade consistency.

✔ Strong Customization Capability

Support for structural optimization, material selection, mold flow analysis, and design improvement.

✔ Flexible Production—from Prototype to Mass Production

Ideal for startups, industrial clients, and global OEMs.

Customer Pain Points We Solve

Pain Point: Weak bonding or peeling

➡ Our metal surface treatment + LSR chemical adhesion guarantees strong bonding.

Pain Point: Tight tolerances required

➡ Precision molds + automated LSR machines ensure consistent accuracy.

Pain Point: Certification & compliance

➡ Full support for FDA, LFGB, ROHS, REACH materials.

Pain Point: Unstable supply chain

➡ Factory-direct manufacturing ensures long-term stable supply.

FAQ

Q1: Do you provide samples? What is the MOQ?

Yes, we offer fast prototyping with a flexible MOQ.

Q2: What types of metal inserts can you overmold?

Stainless steel, aluminum, brass, zinc alloy, and CNC-machined metal parts.

Q3: How do you ensure strong silicone–metal bonding?

Through surface treatment, plasma cleaning, primer coating, and LSR chemical bonding.

Q4: Can you support design optimization?

Yes, we provide DFM, structure evaluation, and mold flow analysis.

Q5: What is the lead time?

Typically 15–30 days depending on project complexity.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883