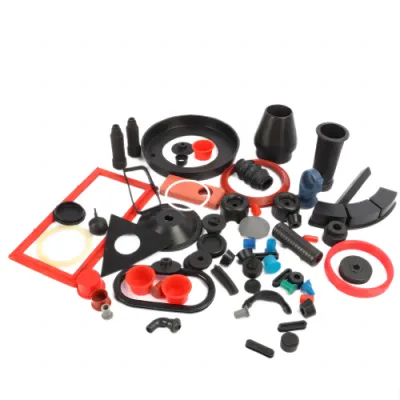

OEM Custom Silicone Rubber Accessories Manufacturer | Professional Silicone Molding Factory

Item specifics

- Certificate

- FDA, ISO13485, CE

- Is there a dust-free workshop

- Yes

- Durable Construction

- Made with Liquid Silicone Rubber for longevity

- Waterproof

- Suitable for wet environments

- Temperature Range

- -40°C to +200°C-40°C to +200°C

Review

Description

Introduction:

At SiliconePlus, we specialize in custom silicone rubber accessories for industrial, electronic, medical, and consumer applications. With decades of expertise in silicone molding, overmolding, and LSR injection molding, our factory provides OEM and ODM services that combine engineering precision, material innovation, and superior product performance.

Whether you need high-performance silicone seals, durable rubber gaskets, or precision overmolded components, SiliconePlus delivers reliable and sustainable silicone solutions tailored to your project requirements.

🔧 Precision Silicone Manufacturing Capabilities

As a professional silicone molding manufacturer, SiliconePlus operates with advanced molding technologies including:

Liquid Silicone Rubber (LSR) Injection Molding – for high-volume production of complex parts with excellent repeatability and fine surface finishes.

Compression and Transfer Molding – ideal for thick-wall or large-sized custom silicone products.

Silicone Overmolding – integrates silicone with plastics, metals, or electronics to improve waterproofing, insulation, and impact resistance.

Our production lines are equipped with fully automated injection systems, vacuum compression presses, and high-precision CNC tooling for mold fabrication. Each process ensures tight dimensional control, smooth surface finish, and consistency in mechanical properties.

🌍 Wide Range of Applications

SiliconePlus provides custom silicone rubber accessories for a wide variety of industries:

Automotive & Transportation:

Engine gaskets, sealing rings, O-rings, dust boots, shock absorbers, and connector covers resistant to oil, heat, and vibration.

Electronics & Electrical Devices:

Keypads, silicone buttons, protective cases, insulators, and overmolded connectors ensuring durability and IP-rated waterproof performance.

Home Appliances & Consumer Electronics:

Anti-slip feet, sealing pads, protective sleeves, and high-temperature-resistant silicone handles for kitchen and home use.

Outdoor & Lifestyle Products:

Foldable silicone cups, travel bottles, lamp rings, and flexible waterproof accessories built for outdoor conditions.

Medical & Laboratory Equipment:

Silicone plugs, tubing, suction cups, gaskets, and housings made from medical-grade LSR compliant with FDA and ISO 13485 standards.

⚙️ Material Advantages & Technical Data

We utilize a diverse range of high-performance silicone materials to meet specific customer requirements:

Material options: Solid silicone rubber (VMQ), LSR (Liquid Silicone Rubber), HCR (High Consistency Rubber), Fluorosilicone (FVMQ).

Hardness range: Shore A 10–90.

Temperature resistance: -60°C to +250°C.

Color customization: Pantone-matched color options with matte, glossy, or textured finishes.

Certifications: FDA, LFGB, RoHS, REACH, ISO 9001, ISO 13485.

Properties: Excellent elasticity, compression set resistance, dielectric strength, UV and ozone stability, and biocompatibility.

Each silicone formula is engineered for its mechanical strength, thermal stability, and chemical resistance, ensuring long-lasting performance even under harsh conditions.

🏭 Why Choose SiliconePlus as Your OEM Silicone Partner?

Full Customization Capability – We support tailor-made shapes, hardness levels, surface textures, and colors for all silicone parts.

In-house Mold Design & Fabrication – Our dedicated mold engineering team ensures precision tooling and rapid development.

Fast Prototyping Service – Sample validation within 5–7 days using advanced CNC and 3D printing.

Comprehensive Quality Control – 100% inspection with advanced measuring instruments (tensile, aging, and hardness testing).

Eco-Friendly Production – All materials comply with environmental standards, ensuring safety for users and sustainability for the planet.

Global OEM/ODM Support – From initial design consultation to mass production and packaging, we serve worldwide customers with efficient communication and on-time delivery.

SiliconePlus empowers global manufacturers to innovate with silicone — improving durability, flexibility, and functionality across industries.

💡 Customer Pain Points & SiliconePlus Solutions

| Customer Challenge | SiliconePlus Solution |

Mold precision and repeatability issues | In-house CNC mold manufacturing with micron-level tolerances |

Silicone aging or deformation under stress | High-purity raw materials with enhanced heat and UV resistance |

| Long lead times for production | Automated LSR injection systems for rapid turnaround |

| Certification requirements (FDA, RoHS, ISO) | Fully certified materials and cleanroom manufacturing |

| Need for custom colors, shapes, or branding | Flexible customization with laser engraving and logo printing |

📦 Packaging & Logistics

All silicone rubber accessories are packed in anti-static, moisture-proof, and dust-free packaging to maintain quality during transportation. We support global shipping via DHL, FedEx, UPS, or freight forwarding according to customer preferences.

❓FAQ – Frequently Asked Questions

Q1: Can you produce custom-designed silicone parts?

Yes, we provide complete OEM/ODM customization including 2D/3D design, mold development, and material selection.

Q2: What’s the typical production time?

Sample production takes 5–7 days. Mass production generally requires 10–25 days depending on complexity.

Q3: Can you supply food-grade or medical-grade materials?

Absolutely. We offer FDA, LFGB, and ISO 13485 certified silicones for safety-critical applications.

Q4: What’s the minimum order quantity (MOQ)?

Our MOQ is flexible depending on your project. Small trial orders are welcome for testing and prototyping.

Q5: How do you ensure product quality?

Every batch undergoes strict QC testing — hardness, tensile strength, aging resistance, and visual inspection — before shipment.