Custom Overmolded Silicone Sealing Gasket | Precision Molded Rubber-TPU & Silicone Parts for Waterproof Medical & Industrial Devices

Item specifics

- Material

- silicone+metal

- color

- Customizable according to your needs

- Technology

- Silicone overmolding process

- Is it spot

- No, these are custom made products

- Product Application Industry

- New energy vehicle industry

- Terms of Payment

- L/C, D/A, D/P, Western Union

Review

Description

Enhance the durability, precision, and waterproof integrity of your devices with our Custom Overmolded Silicone Sealing Gaskets, expertly engineered for demanding medical, industrial, and electronic applications. At SiliconePlus, we specialize in precision silicone injection molding and overmolding techniques that deliver superior sealing performance in the most challenging environments.

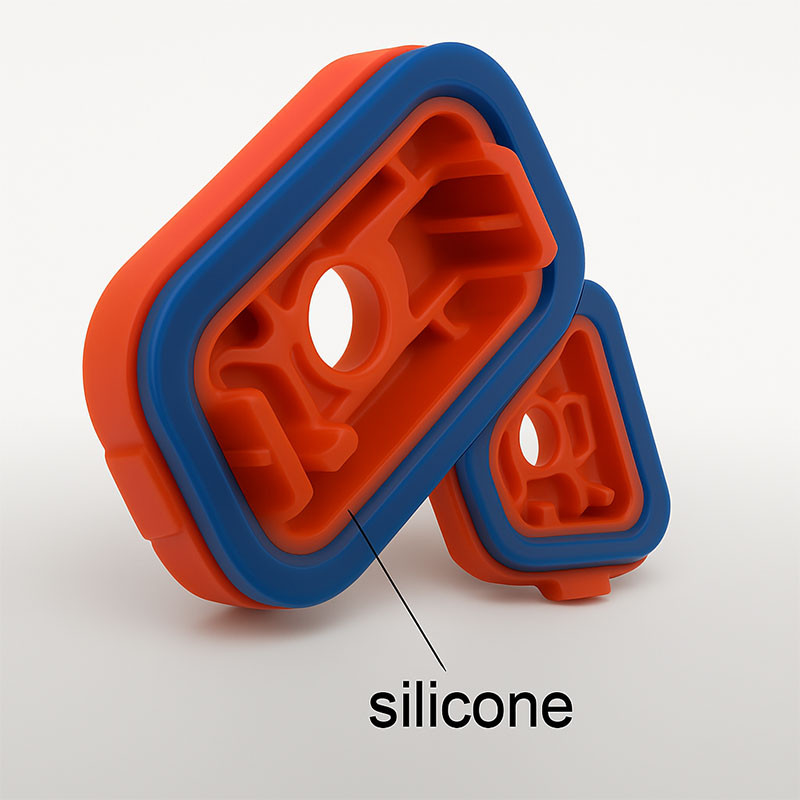

Our overmolded gaskets combine high-grade silicone rubber with rigid or semi-rigid substrates such as TPU, plastics, or metals, creating a seamless bond that enhances both mechanical strength and environmental resistance. This dual-material design optimizes both flexibility and rigidity, ensuring that the gasket conforms to device geometries while providing a secure and lasting seal.

Key Features:

Premium Silicone Material: FDA, LFGB, USP Class VI certified, ensuring biocompatibility and safety for medical devices.

Advanced Overmolding Technology: Combines silicone with thermoplastic materials (TPU/PC/ABS) for superior adhesion and performance.

Excellent Waterproof & Dustproof Properties: Achieves IP67+ sealing standards, protecting sensitive electronics and components from moisture, dust, and contaminants.

Customizable Solutions: Tailor-made sizes, hardness, colors, and structural designs based on your project requirements.

High-Temperature Resistance: Operates efficiently in extreme conditions ranging from -40°C to 200°C.

Chemical Resistance: Withstands exposure to disinfectants, saline, and industrial cleaning agents.

Precision Engineering: Suitable for complex, tight-tolerance applications in wearables, medical implants, diagnostic equipment, and industrial machinery.

Applications:

Medical Devices: Implantable components, surgical instruments, continuous glucose monitors, and diagnostic equipment.

Industrial Equipment: Sealing for pumps, valves, and sensors exposed to harsh industrial conditions.

Electronics & Consumer Devices: Waterproofing for smart wearables, handheld tools, and ruggedized electronic products.

Automotive & Aerospace: Gaskets and seals for systems requiring robust thermal and chemical stability.

Why Choose SiliconePlus?

Expertise in Custom Silicone Overmolding: Decades of experience in developing tailored silicone solutions for high-precision industries.

Certified Manufacturing: ISO 13485, ISO 9001 certified production facilities ensuring consistent quality and compliance.

Flexible Production: Capable of supporting both small-scale prototyping and large-volume production with rapid turnaround.

Comprehensive Support: From material selection, mold design, to final production, our team partners with you at every step.

Customization Options:

Dual-shot or insert molding options

Shore hardness ranging from 20A to 80A

Multiple color matching via Pantone codes

Surface treatments for enhanced grip or aesthetics

Integration with metal or plastic components

Invest in high-performance silicone overmolded gaskets that deliver unmatched protection, durability, and regulatory compliance. Contact SiliconePlus today to discuss your custom sealing solution and let us help you bring your product to market with confidence.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883