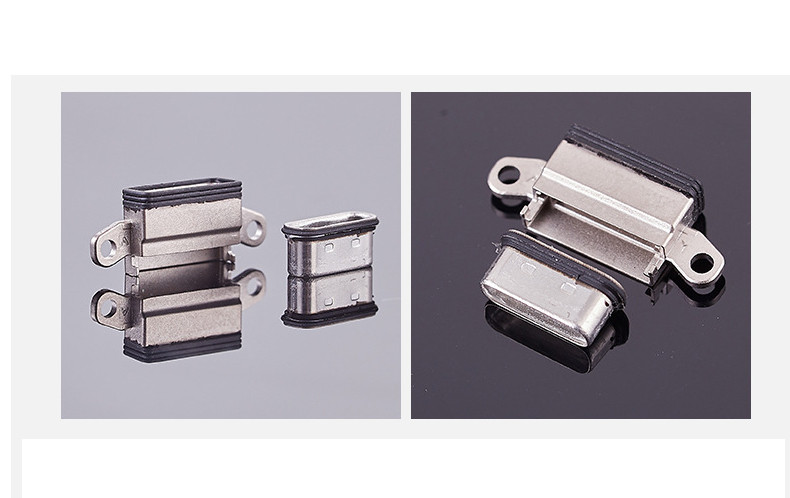

1. Unstable waterproof performancePain point: The waterproof processing process of the Type-C interface is not fine, and the sealing is not tight enough, resulting in unstable waterproof effect and difficulty in meeting the IP68 waterproof standard.

Solution: Siliconeplus uses high-precision encapsulation technology to ensure that the product is perfectly sealed during production, has excellent waterproof performance, and has undergone rigorous waterproof testing to ensure its stability in extreme environments.

2. Silicone is not firmly bonded to the substrate

Pain point: The adhesion between silicone and substrates such as metal or plastic is insufficient, and it is easy to debond or deform during use, affecting the protective effect.

Solution: Siliconeplus uses mature bonding technology and professional equipment to ensure that silicone is firmly bonded to the substrate, improve product durability and waterproof performance, and ensure long-lasting protective effect.

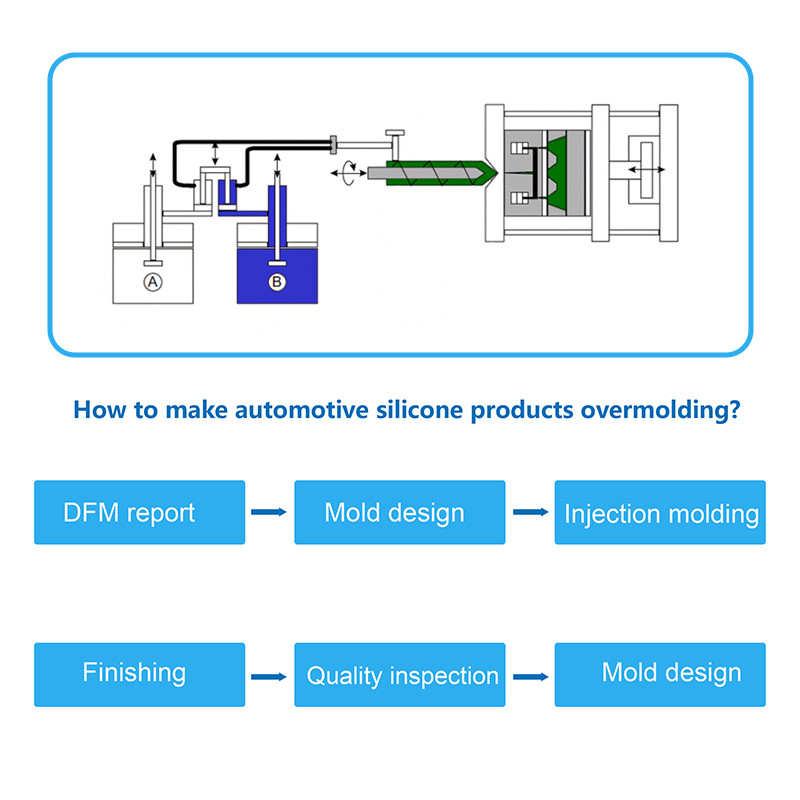

3. Customization needs are difficult to meet

Pain point: Customers have different customization needs, such as size, color, function, etc., but many manufacturers find it difficult to provide flexible customization services, especially small batch orders.

Solution: Siliconeplus has its own mold room and flexible production capacity, which can quickly respond to customization needs and provide personalized solutions, including a variety of designs, functions and color options.

4. Consistency issues in mass production

Pain point: During mass production, the quality of Type-C silicone encapsulated products is prone to inconsistency, affecting the overall performance of the product.

Solution: Through a rigorous quality management system, Siliconeplus ensures that the quality of each batch of products is consistent, ensuring that every product received by customers meets high standards.

5. Unable to seal the glue

Pain point: During the processing of the product, the seal is not tight enough, resulting in substandard waterproof and sealing effects.

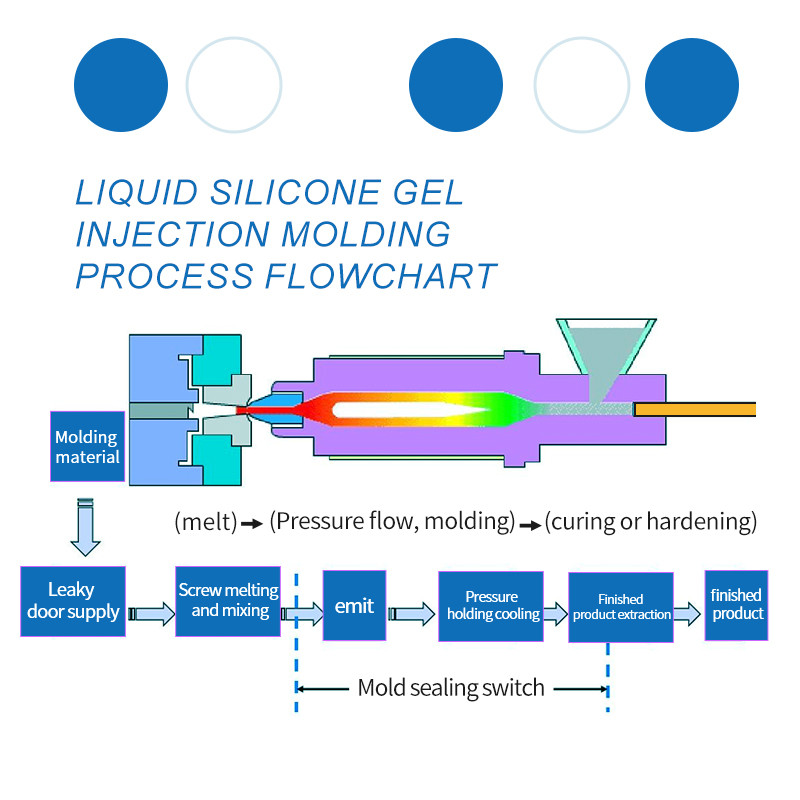

Solution: Siliconeplus uses high-precision injection equipment to ensure that each product is perfectly sealed during the sealing process, and passes multi-layer quality inspections to ensure that the sealing effect is stable and reliable.

6. Product structure cannot be positioned

Pain point: It is difficult to accurately position the product in the mold, resulting in uneven encapsulation, affecting the appearance and function of the product.

Solution: Siliconeplus relies on rich mold design experience to optimize the mold structure design to ensure that the product is accurately positioned in the mold, thereby ensuring the uniformity and aesthetics of the encapsulation process.

7. Product demoulding is difficult

Pain point: During the production process, it is difficult for the product to be demoulded smoothly, affecting production efficiency and easily damaging the product surface.

Solution: Siliconeplus uses efficient demoulding process and mold surface treatment technology to ensure smooth demoulding of products, keep the surface intact, and improve production efficiency.

8. Long delivery cycle and unstable supply chain

Pain point: The order volume is large but the production cycle is too long, which affects market supply and even misses the sales opportunity.

Solution: Siliconeplus greatly shortens the production cycle through independent mold opening and integrated production, ensures fast delivery, helps customers launch products on time, and improves market competitiveness.

Through comprehensive solutions for these common pain points, Siliconeplus has demonstrated its technical advantages in waterproof Type-C silicone encapsulation processing, and can provide customers with high-quality, customized, stable and reliable products, helping customers effectively cope with challenges in production and improve market competitiveness.