liquid silicone rubber injection molding | lsr silicone molding | silicone product custom

- Model

- 1-lyasilicone20240812

Item specifics

- Flavor

- Catnip/Silvervine/Gall Fruit

- color

- Green/Purple

- Base material

- Silicone

- length

- 33cm

- fixing method

- Non-slip suction cups

- devise

- Replaceable food balls

Review

Description

Solving the Challenges of Silicone Overmolding for FPC Circuit Boards

The sealing is not tight, affecting the protection performance of the FPC circuit board

For FPC circuit boards, the quality of the sealing directly affects their performance in complex environments. Uneven sealing may cause the circuit board to be exposed to the outside world, affecting the electrical performance. Siliconeplus uses advanced sealing technology to ensure that every detail is properly handled, prevent the problem of loose sealing, and ensure the stability and reliability of the circuit board in extreme environments such as high humidity and high temperature resistance.

Inaccurate positioning leads to functional failure

In the overmolding of FPC circuit boards, inaccurate positioning can easily cause unqualified products and affect mass production efficiency. Siliconeplus uses high-precision mold design and precision equipment to ensure that the positioning of silicone on FPC is absolutely accurate, so that every detail meets the product functional requirements, greatly reducing rework and scrap rates.

Difficult demoulding affects production efficiency and quality

When silicone is coated on FPC circuit boards, demoulding is a key link. Unsmooth demoulding can easily damage the surface of the circuit board and even affect its conductive properties. Siliconeplus uses special demolding technology to reduce the adhesion of silicone in the mold, ensure a smooth demolding process, and ensure the integrity and quality of each FPC product.

Weak adhesive affects long-term stability

Weak adhesive is a common problem faced by FPC encapsulated products, especially in high temperature or high pressure environments. Siliconeplus uses professional adhesive technology and material surface treatment technology to ensure a firm bond between silicone and FPC, so that the product can still maintain strong adhesion and functional performance in various extreme application scenarios.

Siliconeplus's commitment

We not only focus on solving various pain points in silicone encapsulation processing, but also provide customers with customized silicone encapsulated FPC solutions through deep technical accumulation. No matter how complex your industry needs are, our team can tailor the most suitable solution for you to ensure the functionality, reliability and market competitiveness of the product.

Application of Silicone + FPC Technology in Medical Device Industry

Application of Silicone + FPC Technology in Medical Device Industry

In the realm of medical technology, where stringent hygiene and mechanical standards are paramount, we've developed a series of silicone-overmolded system solutions. These solutions are tailored to meet the unique demands of medical applications, ensuring they adhere to rigorous cleanliness and durability requirements. Thanks to their non-adhesive surface and other features, they are easily cleaned, capable of withstanding steam sterilization, flexible, resistant to extreme temperatures, and compliant with DIN EN ISO 10993-5 standards. This renders them ideal for maintaining hygiene and resilience in everyday medical practices.

Silicone Overmolding System Solutions :

●To address the specific needs of the medical field, we provide personalized silicone-overmolded system solutions comprising connectors, overmolded components, and cables, complete with assembly services and optional laser marking. Our connectors with silicone overmolding and cable assembly are meticulously crafted using carefully selected materials to optimize tactile sensation, hygiene, and longevity. Additionally, we've established partnerships with leading cable manufacturers to ensure the highest quality standards.

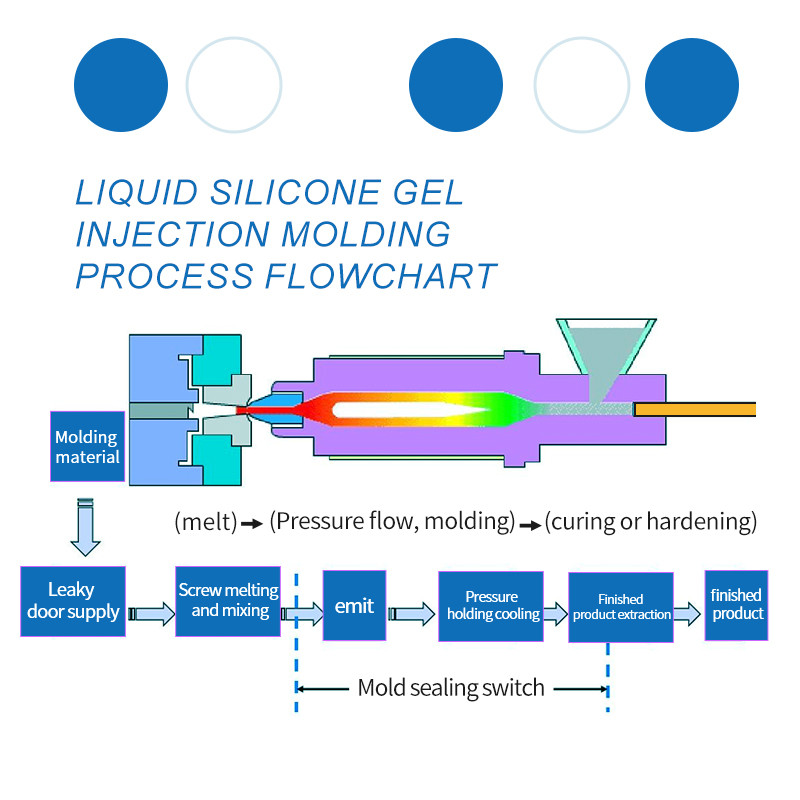

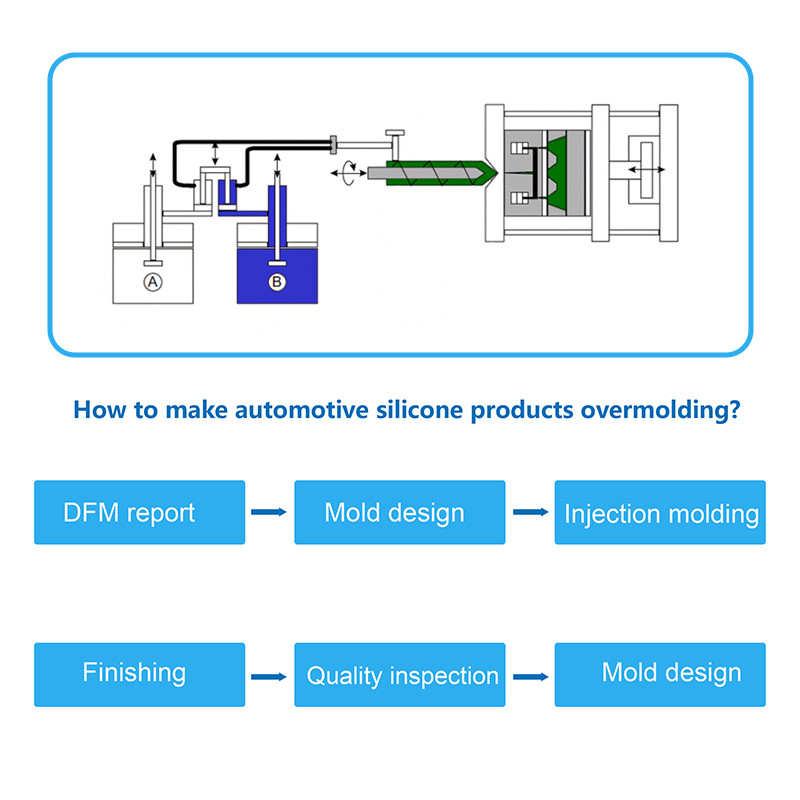

Product Customization Process

Application scenarios of silicone + FPC process

Catnip Ball Silicone Toy Frequently Asked Questions

Q1: Are you a factory or a trading company?

siliconeplus is a certified manufacturer integrating industry and trade, Mainly engaged in all kinds of silicone or rubber material products.

Q2: What quality control processes do you have?

1. Raw material inspection: We use high-standard silicone raw materials and conduct strict inspections to ensure that they are non-toxic, odorless, non-polluting, and meet international safety standards.

2. Production process monitoring: During the production process, we monitor key parameters such as temperature and pressure in real time to ensure stable process and consistent products.

3. Finished product inspection: Before silicone products leave the factory, we conduct comprehensive finished product inspections to ensure that the products are defect-free and meet design requirements.

Continuous improvement: We are constantly pursuing excellence and improving product quality and management level through continuous quality improvement activities such as quality seminars and employee training.

Q3:Do we accept customized?

Yes, we can make products as your requirement.

After get your design 2D/3D files, our R & D team can provide the deisgn and quotation with 1-2 days.

- If the above products are not suitable for your workpiece, please tell us your needs and we will provide you with the most satisfactory drawings.

- contact us