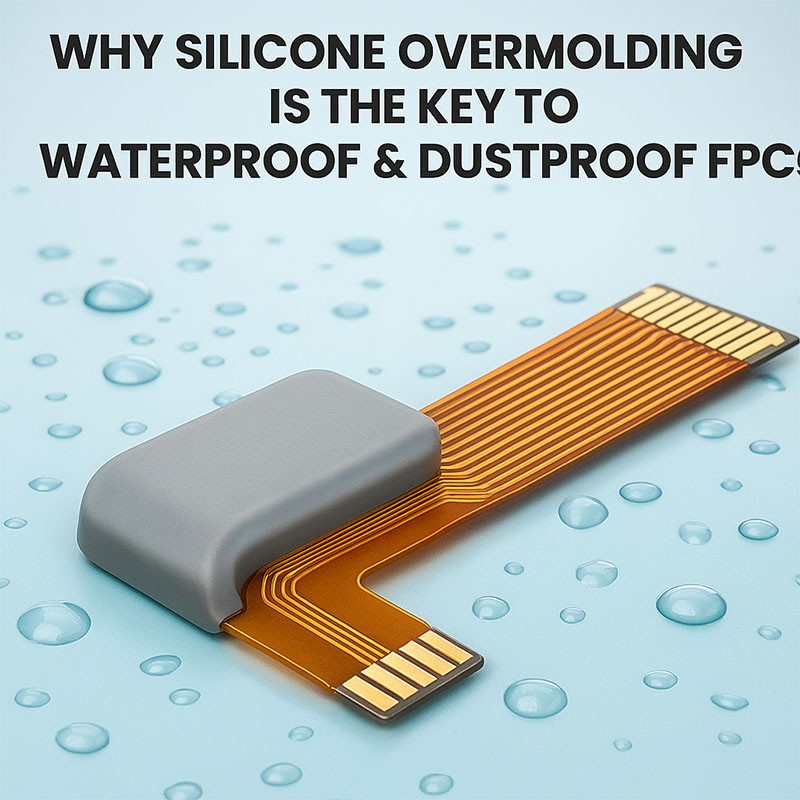

Why Silicone Overmolding Is the Key to Waterproof and Dustproof FPCs

- Share

- publisher

- siliconeplus

- Issue Time

- Nov 7,2025

Summary

Silicone overmolding provides flexible protection for FPCs, ensuring durability and reliability in harsh environments.

Introduction:

In today’s rapidly advancing electronic industry, Flexible Printed Circuits (FPCs) have become indispensable due to their lightweight, compact, and highly adaptable nature. However, as the demand for durable and reliable electronic components increases, the challenge of protecting FPCs from environmental hazards such as moisture, dust, and mechanical stress has become more critical than ever. Silicone overmolding emerges as the most effective solution for achieving waterproof and dustproof protection, ensuring FPCs perform flawlessly in even the harshest conditions.

The Critical Importance of Protecting FPCs in Modern Electronics

Flexible Printed Circuits are extensively used across various industries, from consumer electronics and medical devices to automotive systems and industrial automation. Their inherent flexibility allows for innovative design, but it also exposes them to environmental risks that can compromise functionality and longevity.

Environmental Challenges Faced by FPCs

Moisture Ingress: Water or humidity can cause short circuits, corrosion, and signal degradation.

Dust and Particulate Contamination: Dust particles can obstruct connections, cause electrical leakage, and accelerate wear.

Mechanical Stress: Flexing, vibrations, and impacts can damage the delicate conductive traces.

Chemical Exposure: Exposure to oils, solvents, or other chemicals can degrade materials over time.

Ensuring robust protection against these factors is essential for maintaining performance, reliability, and longevity of FPC-based devices.

What Is Silicone Overmolding?

Silicone overmolding involves encapsulating the FPC with a specially formulated silicone elastomer, creating a protective barrier around the circuit. This process not only shields against environmental hazards but also enhances mechanical durability.

Key Features of Silicone Overmolding

Excellent Waterproofing: Silicone exhibits high resistance to water ingress, making it ideal for waterproof FPC applications.

Superior Dustproof Capability: The silicone layer prevents dust particles from reaching sensitive areas.

Flexibility and Elasticity: Maintains circuit flexibility, allowing for bending and movement without damage.

Chemical Resistance: Resists oils, solvents, and other chemicals often encountered in industrial environments.

Temperature Tolerance: Performs reliably across a broad temperature range, from -60°C to +200°C.

Biocompatibility: Suitable for medical applications requiring sterile and safe encapsulation.

The Science Behind Silicone Overmolding

Silicone elastomers used in overmolding are highly cross-linked polymers derived from silicone monomers. Their unique molecular structure provides outstanding hydrophobic properties and elasticity.

Material Composition and Processing

Material Composition: Typically, addition-cure (RTV silicone) or condensation-cure formulations are used.

Processing Techniques: The process involves precision injection molding or potting methods, ensuring uniform coverage and adhesion.

Curing Process: The silicone is cured at controlled temperatures, forming a strong bond with the FPC surface.

Adhesion and Compatibility

Proper surface preparation—such as plasma treatment or primer application—ensures excellent adhesion between the silicone and the FPC substrate, preventing delamination over time.

Advantages of Silicone Overmolding for FPCs

1. Unmatched Waterproof and Dustproof Performance

Silicone’s hydrophobic nature creates a seamless barrier against water and dust. It prevents moisture penetration, which is crucial for outdoor, marine, and industrial applications where exposure to elements is inevitable.

2. Mechanical Durability and Flexibility

Unlike rigid encapsulants, silicone maintains elasticity even under repeated flexing, allowing FPCs to bend, fold, and move without risking trace fractures or connectivity issues.

3. Enhanced Thermal Management

Silicone’s high thermal stability helps dissipate heat effectively, preventing overheating and ensuring consistent operation in high-temperature environments.

4. Chemical and UV Resistance

Silicone overmolds resist degradation from chemicals, oils, and UV radiation, extending the lifespan of FPCs in harsh industrial, outdoor, or medical environments.

5. Biocompatibility and Safety

In medical devices and wearable technology, silicone’s biocompatibility ensures safety and sterility, crucial for implantable or skin-contact FPC applications.

Design Considerations for Silicone Overmolding of FPCs

Achieving optimal protection requires meticulous design and process control:

| Aspect | Considerations |

Material Selection | Use high-quality, medical-grade or industrial-grade silicone elastomers tailored for specific environmental conditions. |

Preparation of FPC Surface | Surface treatments such as plasma cleaning or primer application improve adhesion. |

| Overmolding Thickness | Sufficient thickness (typically 1-3 mm) balances protection with flexibility. |

| Curing Process | Controlled curing parameters prevent residual stresses and ensure complete polymerization. |

| Design for Flexibility | Incorporate strain relief features to prevent stress concentrations during bending. |

Applications of Silicone Overmolded FPCs

Consumer Electronics

Wearable Devices: Smartwatches, fitness trackers requiring water and dust resistance.

Mobile Devices: Foldable smartphones with flexible circuits protected against environmental exposure.

Medical Devices

Implantable Sensors: Silicone encapsulation ensures biocompatibility and protection against bodily fluids.

Portable Medical Equipment: Ensures durability in sterile, moist, or dusty environments.

Automotive and Industrial

Automotive Sensors and Controls: Resistance to oil, water, and vibration.

Industrial Automation: Protection against dust, chemicals, and mechanical stress in harsh environments.

Marine and Outdoor Equipment

Marine Electronics: Waterproofing essential for saltwater exposure.

Outdoor Sensors: Dust and water ingress prevention for remote outdoor monitoring.

Case Study: Silicone Overmolding in High-Performance Wearables

A leading manufacturer of fitness trackers integrated silicone overmolding into their design process. The result was a waterproof, dustproof device that maintained flexibility during daily use, even after thousands of bending cycles. The silicone encapsulation not only protected the delicate FPCs but also enhanced user comfort, providing a seamless, skin-friendly surface.

Future Trends in Silicone Overmolding for FPCs

Smart Overmolds:

Integration of sensor elements within the silicone layer for self-monitoring and diagnostics.Nanocomposite Silicone:

Incorporation of nanoparticles to improve thermal conductivity and mechanical strength.Advanced Manufacturing Techniques:

Adoption of additive manufacturing for complex, multi-material encapsulations.Conclusion: Why Silicone Overmolding Is Indispensable for Water and Dustproof FPCs

Silicone overmolding stands out as the most reliable, flexible, and durable solution for protecting Flexible Printed Circuits against water, dust, and mechanical stress. Its superior chemical and thermal resistance, combined with biocompatibility and flexibility, makes it the go-to choice for a wide array of applications demanding high-performance protection.

By leveraging advanced silicone materials and precise overmolding techniques, manufacturers can significantly extend the lifespan of FPCs, reduce maintenance costs, and ensure uninterrupted device operation in even the most challenging environments. As technological innovation continues, silicone overmolding will remain at the forefront of protective solutions for the next generation of robust, waterproof, and dustproof electronic devices.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883