Why Liquid Silicone Rubber (LSR) Is the Future of Medical Devices

- Share

- publisher

- siliconeplus

- Issue Time

- Sep 11,2025

Summary

Liquid Silicone Rubber (LSR) is revolutionizing medical devices with biocompatibility,precision, and cost efficiency.

Introduction: The Evolution of Medical Materials and the Rise of LSR

In the rapidly advancing landscape of healthcare technology, material innovation plays a pivotal role in shaping the efficacy, safety, and performance of medical devices. Among the groundbreaking materials transforming this industry, Liquid Silicone Rubber (LSR) stands out as a game-changer. Its unique combination of biocompatibility, flexibility, chemical stability, and manufacturing efficiency positions LSR as the future of medical device production. As healthcare providers demand safer, more reliable, and cost-effective solutions, the adoption of LSR-based components continues to accelerate, promising a new era of innovation and patient care excellence.

Superior Biocompatibility and Safety Profile of LSR for Medical Devices

Biocompatibility is the cornerstone of any material used in healthcare. LSR's non-toxic, hypoallergenic nature makes it the ideal choice for a broad spectrum of medical applications, from implantable devices to disposables.

Compliance with International Standards

1.ISO 10993 Certification: Ensures LSR's safety for prolonged tissue contact.

2.USP Class VI: Confirms non-leaching, non-toxic properties suitable for critical applications.

3.FDA Approval: Many LSR formulations are recognized as medical-grade, allowing for seamless integration into FDA-regulated devices.

Applications Benefiting from Biocompatibility

1.Catheter Tubing: Flexible, durable, and safe for long-term use.

2.Sealing Rings and Gaskets: Ensures airtight and sterile seals.

3.Sensor Encapsulation: Protects delicate electronics while maintaining biocompatibility.

4.Wearable Medical Devices: Comfortably conforms to the skin, reducing irritation.

Durability and Sterilization Compatibility of LSR

Medical devices must withstand rigorous sterilization without compromising their integrity. LSR’s resistance to high temperatures, radiation, and chemicals makes it an ideal material for sterilizable components.

Sterilization Methods Compatible with LSR

| Sterilization Method | Compatibility & Notes |

| Autoclaving (Steam) | Highly resistant; maintains properties after multiple cycles. |

Gamma Radiation | Stable; minimal degradation, suitable for single-use devices. |

| Ethylene Oxide (EtO) | Compatible; preserves mechanical and chemical properties. |

| Plasma Sterilization | Suitable, provided conditions are optimized. |

Impact on Device Longevity

LSR's chemical inertness ensures that devices retain their mechanical properties and clarity even after repeated sterilizations. This extends the lifespan of implantable and reusable devices, reducing costs and improving patient safety.

Design Flexibility and Precision Manufacturing with LSR

The molecular structure of LSR allows for complex geometries and precise microfeatures that are difficult to achieve with traditional materials.

Design Advantages:

1.Thin-walled components: Enables lightweight, minimally invasive device designs.

2.Microchannels and intricate details: Critical for sensors and drug delivery systems.

3.Color customization: Facilitates visual indicators or branding.

4.Transparent or translucent options: Useful for optical devices and diagnostics.

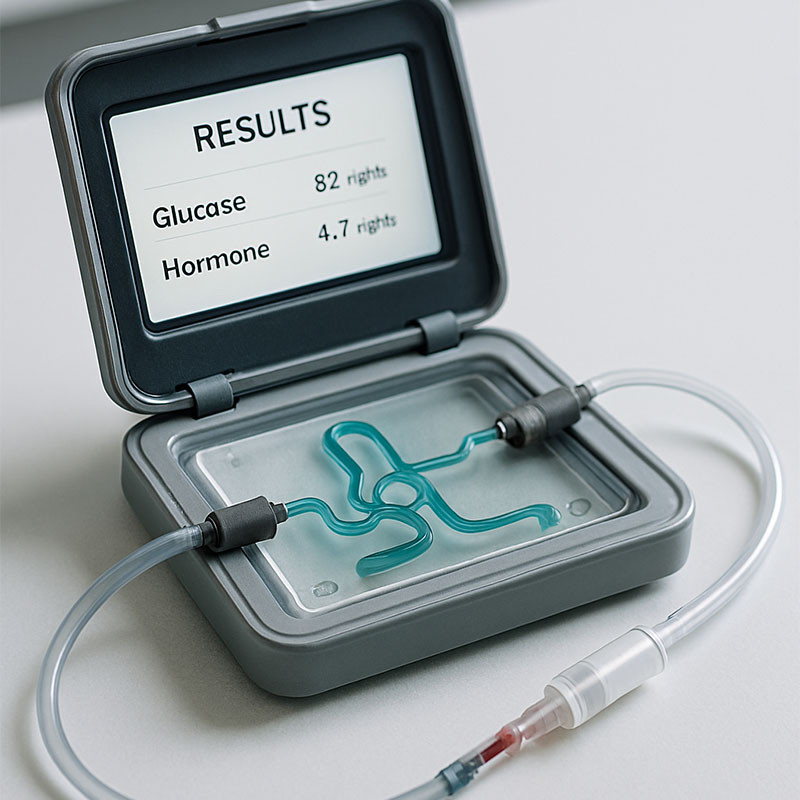

Case Study: LSR in Microfluidic Devices

Microfluidics demand precise control of fluids at microscopic scales. LSR’s smooth surface finish and dimensional stability make it the material of choice for these applications, ensuring reliable performance and ease of integration with sensors and electronics.

Cost-Effectiveness and Scalability of LSR Production

The injection molding process for LSR is highly automatable, allowing for mass production of complex parts at lower costs compared to traditional silicone or elastomer manufacturing.

Economic Benefits:

High throughput: Rapid cycle times reduce per-unit costs.

Minimal waste: Precise molding minimizes scrap.

Consistent quality: Reduces rework and quality control expenses.

Reduced assembly time: Integrated components streamline manufacturing.

Impact on Medical Device Market This cost-efficiency accelerates the availability of affordable, high-quality medical devices, particularly in resource-limited settings, expanding access to advanced healthcare solutions worldwide.

Environmental and Sustainability Considerations

While silicone is a synthetic material, advancements in LSR manufacturing have focused on reducing environmental impact.

Sustainable Practices in LSR Production:

1.Energy-efficient processes

2.Recycling of scrap material

3.Longer-lasting devices that reduce waste over time

4.Potential for Future Eco-Friendly Innovations

5.Research into biodegradable silicones and renewable raw materials may further enhance the sustainability profile of LSR, aligning

6.with global efforts for environmentally responsible medical manufacturing.

Emerging Trends and Future Outlook

Liquid Silicone Rubber is poised to dominate the next decade of medical device innovation due to its versatile properties and manufacturing advantages.

Key Trends:

1.Integration with electronics: LSR as an encapsulant for wearable and implantable sensors.

2.Personalized medicine: Custom, patient-specific devices produced via rapid injection molding.

3.Smart medical devices: Compatibility with biocompatible, flexible electronics.

4.Advanced sterilization techniques: Ensuring long-term device performance.

Research and Development Focus:

1.Enhanced biocompatibility for even more sensitive applications.

2.Nano-engineering to improve surface properties.

3.Hybrid materials combining LSR with other biocompatible polymers for multifunctionality.

Conclusion: Why LSR Will Lead the Future of Medical Devices

Liquid Silicone Rubber (LSR) offers an unparalleled combination of biocompatibility, durability, design flexibility, and manufacturing efficiency that positions it as the cornerstone material for future medical innovations. As the healthcare industry continues to demand safer, cost-effective, and high-performance devices, LSR’s versatile properties will enable manufacturers to meet these challenges head-on. Embracing LSR is not just an evolution—it is a revolution in medical device technology, setting new standards for patient safety, device reliability, and manufacturing excellence in the years to come.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883