What is the process of silicone molds?

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- Dec 19,2024

Summary

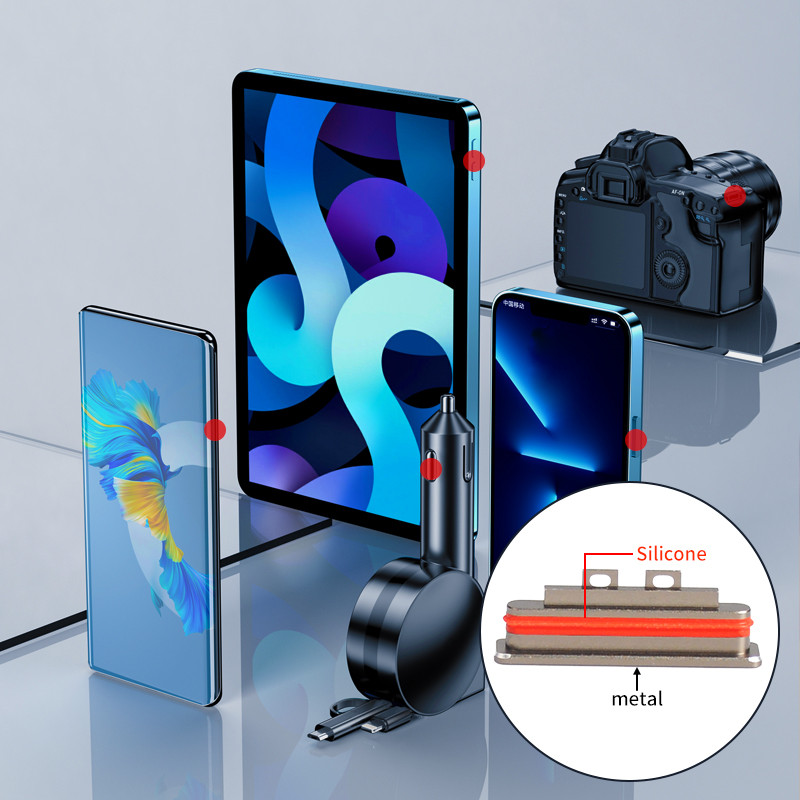

Silicone molds are made by pouring liquid silicone into a mold cavity, curing it, then demolding. This process ensures flexibility, durability, and precision for various applications.

Creating silicone molds is a fascinating and precise process, but without understanding the steps, it can feel overwhelming. Whether you're a beginner or seasoned professional, the right information simplifies the journey.

Silicone molds are made by pouring liquid silicone into a mold cavity, allowing it to cure, and removing the finished product. This process ensures flexibility, durability, and precision.

Let me walk you through the details, from preparation to application, to help you master the art of silicone mold-making.

[Table of Contents]

.Do silicone molds need to be greased?

.How long does it take for silicone mold to cure?

.What are the disadvantages of silicone molds?

.Do you put silicone molds directly in the oven?

Do silicone molds need to be greased?

Sometimes, you may wonder if greasing silicone molds is necessary, especially when they are marketed as "non-stick."

In most cases, silicone molds do not need to be greased because their non-stick surface ensures easy release of the product. However, for certain recipes or materials, a light grease coat can improve results.

When and why should you grease silicone molds?

Silicone molds are naturally non-stick, making them ideal for baking, casting resin, or making soap. However, there are exceptions:

For baking: Sticky or high-sugar recipes like caramel or toffee might benefit from a light spray of oil or butter.

Resin or plaster casting: A release agent might be necessary to prevent small details from sticking.

Grease or no grease: Practical tips

|

Use case |

Greasing recommended?

|

Tips

|

|

Baking

|

Sometimes

|

Light oil spray for sticky doughs

|

|

Resin casting

|

Often

|

Use specialized mold-release sprays

|

|

Soap making

|

Rarely

|

Silicone's flexibility usually suffices

|

How long does it take for silicone mold to cure?

Time can be a critical factor in mold-making, especially when working under tight deadlines or specific conditions.

Silicone molds typically take 24-48 hours to cure, depending on the type of silicone used, temperature, and humidity levels.

Dive deeper: Factors affecting curing time

Curing time depends on the following:

Silicone type: Platinum-cured silicone usually cures faster (6-24 hours) than tin-cured silicone (24-48 hours).

Environmental conditions: Warmer temperatures and lower humidity speed up curing. Cold or damp environments slow it down.

Thickness: Thicker molds might require longer curing times for the center to fully harden.

Pro tip: Speeding up the process

Use a curing oven to maintain a consistent warm temperature.

Avoid adding excessive catalyst, which can compromise mold quality.

What are the disadvantages of silicone molds?

While silicone molds offer many advantages, such as flexibility and heat resistance, they also have limitations.

Silicone molds can be expensive, prone to tearing with extended use, and may struggle with highly detailed designs.

Dive deeper: Exploring the downsides

High upfront cost: Silicone materials can be pricey compared to plastic or metal molds.

Durability concerns: Prolonged use or exposure to harsh chemicals can weaken silicone, leading to tears or deformation.

Detail limitations: Although silicone is flexible, extremely intricate patterns might require stiffer molds for better replication.

Comparison: Silicone molds vs. other mold types

|

Mold Type

|

Pros

|

Cons

|

|

Silicone

|

Flexible, non-stick, heat-resistant

|

Expensive, prone to tearing

|

|

Metal

|

Durable, reusable

|

Less flexible, requires greasing

|

|

Plastic

|

Affordable, lightweight

|

Brittle, limited heat resistance

|

Do you put silicone molds directly in the oven?

When you're working with silicone molds for baking, the question of safety is paramount.

Yes, silicone molds can go directly into the oven as they are heat-resistant, usually up to 450°F (232°C), but always check the manufacturer's specifications first.

Dive deeper: Oven safety tips for silicone molds

Check heat tolerance: Ensure your mold is rated for high temperatures.

Even heat distribution: Place molds on a baking sheet to avoid spills and ensure even heat exposure.

Inspect before use: Look for any damage or wear that might affect performance.

Myth-busting: Will silicone melt in the oven?

No, silicone molds won't melt under normal baking temperatures. They are designed to withstand heat, making them a reliable choice for cakes, muffins, and other treats.

Conclusion

Silicone molds are versatile tools for baking, crafting, and beyond, but understanding their process, care, and limitations is key to success. From curing times to safety in the oven, every detail matters.