What is the process of silicone mold development and customization?

- Share

- publisher

- https://www.siliconeplus.net/

- Issue Time

- Mar 8,2025

Summary

The silicone mold development process includes requirement analysis, CAD design, precise CNC manufacturing, assembly, trial molding, and optimization to ensure product quality, durability.

What is the process of silicone mold development and customization?

The development and customization of silicone molds is a complex and intricate process that involves multiple links and key technologies. The following are the main processes for developing and customizing silicone molds:

1、 Project Preparation and Requirements Analysis

Gain a deep understanding of customer needs, including key information such as the purpose, size specifications, appearance requirements, and performance parameters of silicone products.

Customers may provide preliminary design sketches or samples as references, and manufacturers need to conduct detailed requirement analysis based on this information.

Evaluate the expected output and material characteristics of the product, especially the liquid silicone encapsulation mold, and pay special attention to the bonding force, sealing, and demolding performance between silicone and embedded materials (such as metal, plastic, etc.) of the mold.

2、 Mold design

On the basis of requirement analysis, use CAD (computer-aided design) software to transform ideas into precise 3D models.

The design includes key elements such as the overall structure design of the mold, parting surface design, gate position, and exhaust hole layout.

Fully consider the fluidity and solidification characteristics of liquid silicone, ensure uniform filling, and avoid the generation of bubbles.

Choose mold materials, often steel or aluminum, such as aluminum alloy, stainless steel, or special alloy steel, to ensure sufficient strength and durability.

Plan a reasonable cooling system to control mold temperature, accelerate the solidification process of liquid silicone gel, and improve production efficiency.

3、 Mould manufacturing

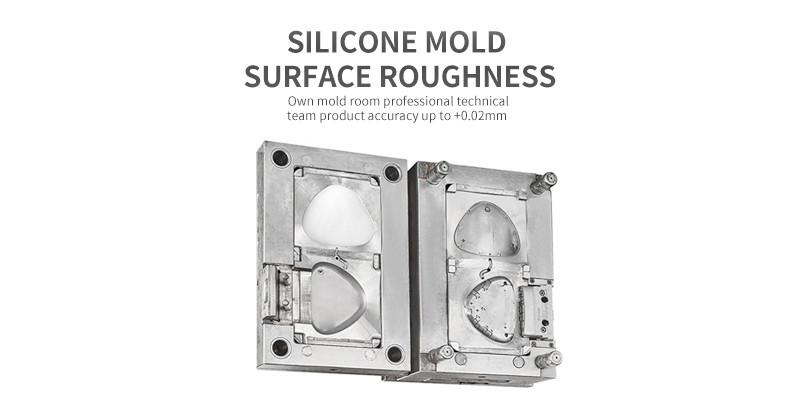

According to the design drawings, precise machining of mold materials is carried out through CNC machining, electrical discharge machining (EDM), wire cutting and other technologies to form various components of the mold.

Strictly control the dimensional accuracy and surface roughness to ensure the sealing and durability of the mold.

Assemble and preliminarily debug the mold components, check whether the opening and closing of the mold are smooth, whether the parting surface is tightly fitted, and whether the cooling system is working properly.

Make a small sample mold for sampling to confirm whether the product color and hardness meet the requirements.

4、 Trial molding and optimization

After assembly and debugging are completed, the mold enters the trial stage, where low-cost trial materials are used to inspect the molding effect of the mold.

Observe the flow of silicone, the difficulty of demolding the product, and the dimensional accuracy and appearance quality after molding.

If problems such as bubbles, material shortage, deformation, etc. are found, targeted adjustments should be made to the mold immediately.

The trial molding process may require multiple rounds until the trial molded product fully meets the design requirements.

5、 Mass production preparation

Develop a detailed production plan, prepare production materials (silicone), and debug production equipment.

Establish a strict quality control system to ensure that every step meets established quality standards.

Consider the packaging and transportation of the product, select appropriate packaging materials and methods to ensure that the product is not damaged during transportation.

Please attach necessary documents such as product manual and certificate of conformity to facilitate customers' understanding of product usage and maintenance methods.

6、 Liquid silicone injection molding

Mix the liquid silicone raw materials evenly in a certain proportion and remove any bubbles and impurities.

Inject the mixed liquid silicone into the mold cavity through a high-pressure injection machine.

7、 Product delivery and continuous optimization

Deliver the product safely and on time to the customer according to the agreed time and method.

Organize and archive relevant production documents and records for future reference and traceability.

The development and customization of silicone molds is a continuous optimization process that requires adjustments and improvements based on production experience and customer feedback.