What is silicone injection molding?

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- Nov 27,2024

Summary

Silicone injection molding is a manufacturing process that uses liquid silicone rubber (LSR) to produce detailed, durable, and high-performance parts.

Silicone injection molding is a fascinating process that plays a key role in manufacturing high-quality silicone parts for various industries. It's efficient, precise, and versatile.

Silicone injection molding is a manufacturing process that uses liquid silicone rubber (LSR) to produce detailed, durable, and high-performance parts.

From medical devices to automotive components, this method is a game-changer for precision and durability. Let’s dive deeper to understand how it works and its importance.

Table of contents

.How does silicone injection molding work?

.What is silicon molding?

.What is the silicone molding method?

.What is the process of silicone?

How does silicone injection molding work?

Silicone injection molding combines heat, pressure, and liquid silicone rubber to create parts with detailed designs and excellent consistency.

The process works by injecting liquid silicone rubber into a heated mold cavity, which then cures and solidifies to form the desired shape.

Dive deeper into the process:

Preparation of Liquid Silicone Rubber (LSR): Two-part LSR (a mixture of silicone elastomers and a curing agent) is mixed in precise ratios.

Injection into the mold: A plunger or screw injects the material into the mold cavity under high pressure.

Heat curing: The mold is heated to high temperatures (usually 120-180°C), which helps the silicone solidify and set into the desired shape.

Demolding and cooling: Once cured, the part is removed from the mold and allowed to cool.

Key Benefits of Silicone Injection Molding:

|

Features

|

Benefits

|

|

High precision

|

Ideal for complex geometries

|

|

Minimal waste

|

Eco-friendly and cost-effective

|

|

Durable and flexible products

|

Suited for medical, automotive, and 3C industries

|

What is silicon molding?

Silicon molding refers to the creation of silicone parts using molding techniques that include injection molding, compression molding, and transfer molding.

Silicon molding is the method of shaping liquid or solid silicone into specific forms using molds.

This term broadly includes multiple molding techniques, each tailored to different needs. Injection molding, for instance, is perfect for high-volume, precision parts, while compression molding suits simpler designs.

What is the silicone molding method?

The silicone molding method encompasses different approaches to forming silicone into usable components, such as injection molding, compression molding, and extrusion.

The silicone molding method involves using various molding techniques to shape silicone into functional components.

Dive deeper into silicone molding methods:

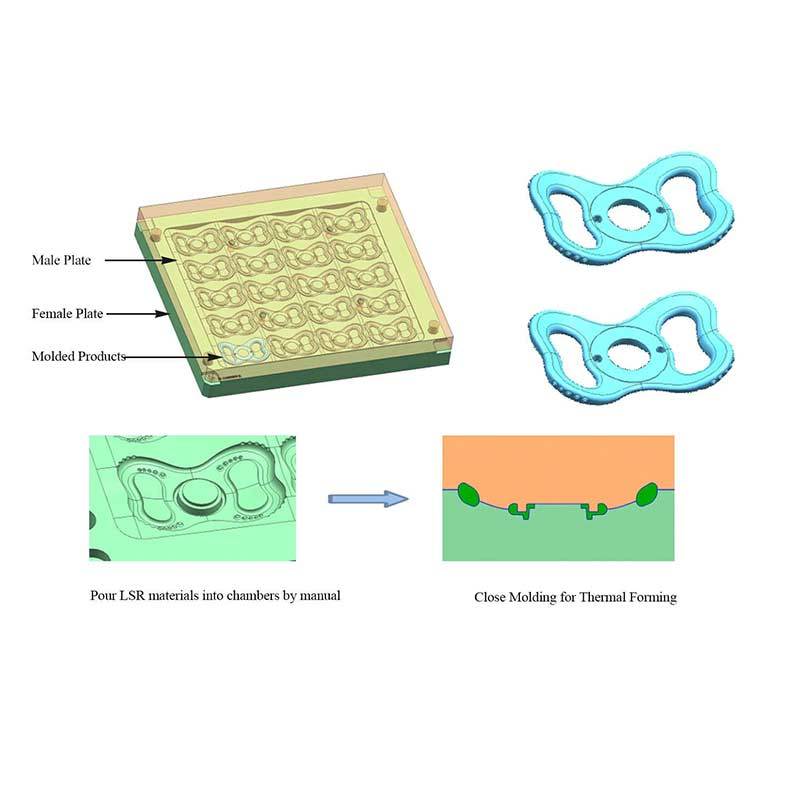

Compression Molding:

Silicone is placed in a preheated mold, compressed, and heated to cure. Suitable for low-volume or less complex parts.

Transfer Molding:

Material is placed in a chamber, then transferred into the mold under heat and pressure.

The most efficient and scalable method for complex designs and high production.

These methods cater to a wide range of applications across industries, offering flexibility and precision.

What is the process of silicone?

The process of silicone typically begins with raw silicone materials being shaped, cured, and finished into functional products.

The process of silicone involves preparing raw silicone, shaping it using molds, and curing it to form solid parts.

Steps in the silicone manufacturing process:

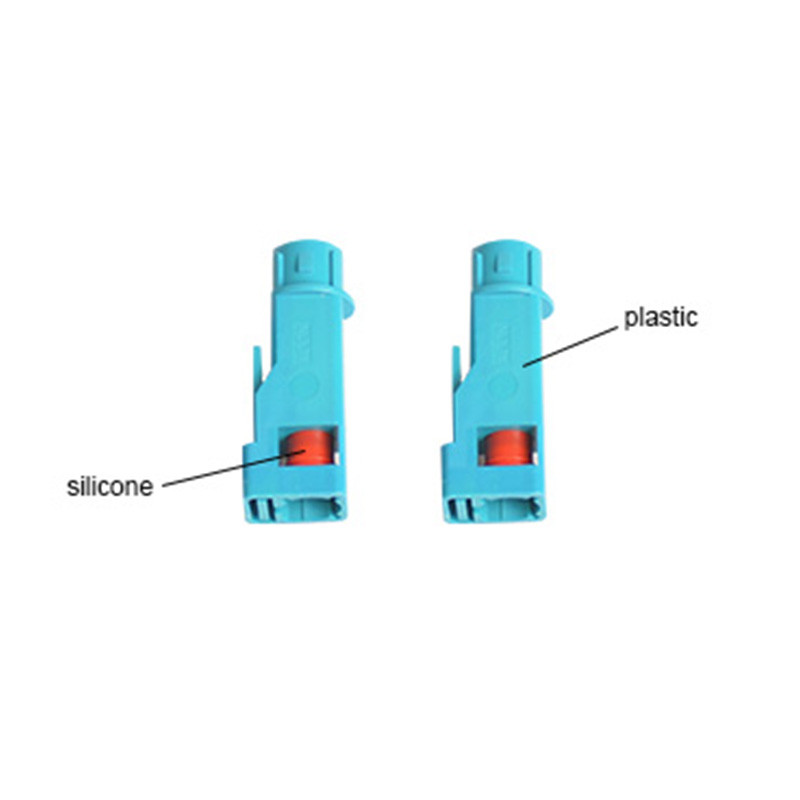

Material Preparation: Silicone elastomers or liquid silicone rubber are blended with additives like pigments or fillers.

Shaping: The material is shaped using molding techniques like injection molding or compression molding.

Curing: Heat or pressure is applied to cure the silicone, solidifying it into the final shape.

Post-Processing: Any extra material (flash) is trimmed, and finishing processes like polishing or coating are applied.

Why is this process important?

The silicone manufacturing process ensures high precision, durability, and adaptability, which are essential for industries such as medical, automotive, and consumer electronics.

Conclusion

Silicone injection molding and related molding methods are indispensable for modern manufacturing. They ensure the creation of durable, flexible, and high-performance silicone parts for industries like automotive, medical, and electronics. By mastering these processes, we enable innovation and quality in countless applications.