What is Silicone Overmolding?

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- Nov 18,2024

Summary

Silicone overmolding provides enhanced durability, seamless bonding without adhesives, superior flexibility for complex designs, making it ideal for medical, automotive, and electronics industries.

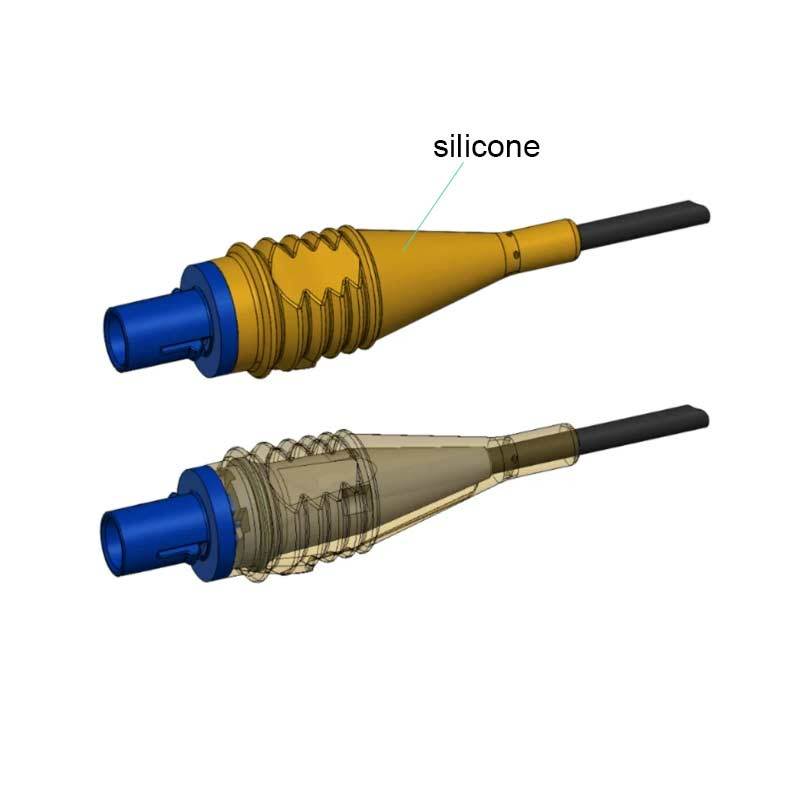

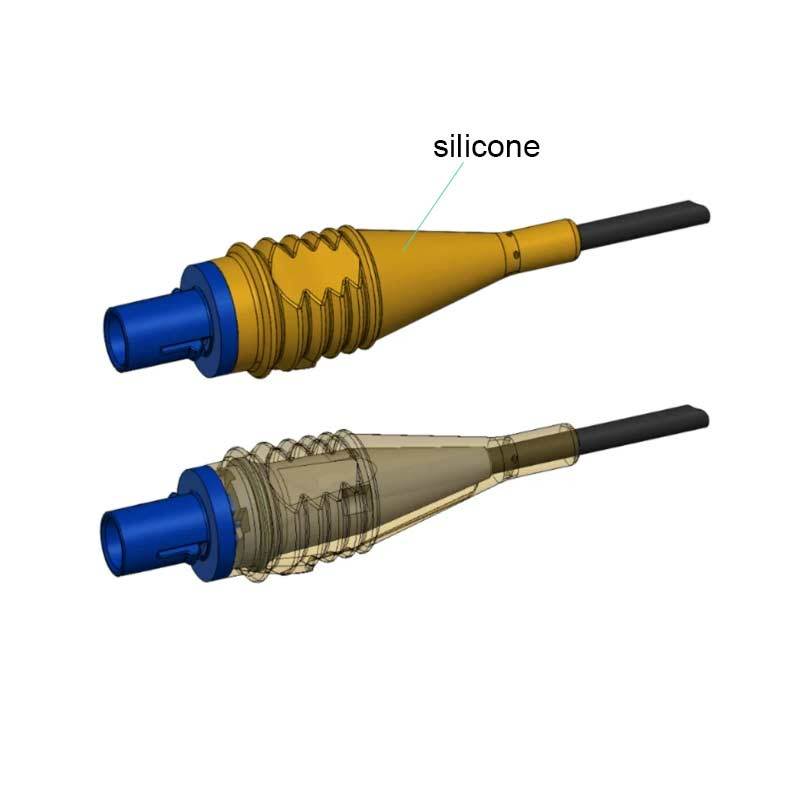

Silicone overmolding is an advanced manufacturing process that combines silicone with other materials, such as metal, plastic, or flexible printed circuits (FPC), to create durable, versatile, and high-performance products. At Siliconeplus, we specialize in delivering tailored silicone overmolding solutions that empower our customers' products across a wide range of industries.

How Does Silicone Overmolding Work?

The process involves injecting liquid silicone rubber (LSR) over a substrate or base material. This allows the silicone to form a strong mechanical or chemical bond, enhancing the product’s structural integrity and functionality. Silicone overmolding is widely used for its ability to integrate multiple materials seamlessly, delivering superior performance in complex applications.

Benefits of Silicone Overmolding

Silicone overmolding offers numerous advantages, making it a preferred choice in industries like medical devices, automotive, electronics, and consumer products:

Enhanced Durability: Silicone's high resistance to extreme temperatures, aging, and environmental factors ensures long-lasting performance.

Seamless Integration: The bonding process ensures a secure connection between materials, eliminating the need for additional adhesives or fasteners.

Superior Flexibility: Silicone’s natural elasticity and adaptability make it ideal for intricate designs and components.

Biocompatibility: For medical applications, silicone's safety and compatibility with human tissue make it a trusted material.

Applications of Silicone Overmolding

At Siliconeplus, we provide custom solutions for industries that require exceptional quality and precision:

Medical Devices: Producing biocompatible parts such as catheters, handles, and wearable devices.

Automotive Industry: Creating seals, gaskets, and vibration-resistant components.

Electronics: Manufacturing waterproof, dustproof enclosures and connectors, including waterproof card trays for leading brands like Huawei, Xiaomi, and OPPO.

Consumer Goods: Developing ergonomic, comfortable products such as grips, handles, and wearables.

Why Choose Siliconeplus for Silicone Overmolding?

At Siliconeplus, our mission is to empower your products through advanced silicone technology. We combine deep expertise in silicone material science with cutting-edge production processes to deliver:

Customized Solutions: Tailored to meet your unique performance requirements.

Exceptional Quality: Leveraging the superior properties of silicone, such as flexibility, anti-aging, and biocompatibility.

Industry-Leading Expertise: Over 20 years of experience and collaborations with top global brands ensure we remain at the forefront of silicone overmolding technology.

Efficient Production: Our in-house mold-making and production capabilities streamline the process, ensuring fast turnaround times and competitive costs.

Partner with Siliconeplus for Innovative Silicone Overmolding Solutions

Silicone overmolding is more than just a process—it’s a way to transform your product's performance and usability. At Siliconeplus, we’re committed to helping our clients succeed by delivering high-quality, innovative solutions tailored to their needs.

Explore the potential of silicone overmolding for your industry. Contact Siliconeplus today to discuss your project and see how we can bring your ideas to life!