What certifications should medical silicone parts comply with?

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- May 23,2025

Summary

In the medical industry, safety and compliance aren't optional—they're the baseline. Medical silicone parts must meet strict regulatory standards before they’re allowed into real-world applications.

In the medical industry, safety and compliance aren't optional—they're the baseline. Medical silicone parts must meet strict regulatory standards before they’re allowed into real-world applications.

Medical silicone parts should comply with ISO 10993, USP Class VI, and often ISO 13485 for manufacturing, to ensure biocompatibility, safety, and regulatory readiness.

Without these certifications, even the most innovative silicone product may never reach the market. Let’s break down what each certification means—and why they matter.

[Table of contents]

.What is ISO 10993 and why is it important for medical silicone?

.What does USP Class VI certification prove?

.Is ISO 13485 certification mandatory for manufacturers?

.Are there other important regional or application-specific certifications?

.Conclusion

What is ISO 10993 and why is it important for medical silicone?

This is the gold standard for evaluating the biocompatibility of medical materials.

ISO 10993 ensures the silicone used in medical devices won’t harm or react with the human body.

Dive Deeper

ISO 10993 is a series of tests assessing how materials interact with living tissue. For medical-grade silicone, the most relevant parts include:

Key Tests in ISO 10993:

| Test Type | Purpose |

| Cytotoxicity | Checks if the material kills cells |

| Sensitization | Determines allergic potential |

| Irritation or Intracutaneous Reactivity | Identifies inflammation risk |

Systemic Toxicity | Evaluates if material is toxic after implantation |

Meeting this standard is essential for Class I to Class III medical devices.

What does USP Class VI certification prove?

USP Class VI evaluates the biological safety of silicone under extreme conditions.

It proves the silicone can withstand sterilization and remains safe for body contact after exposure to heat and solvents.

Dive Deeper

USP (United States Pharmacopeia) testing involves exposing the material to high heat and chemical stress, then checking for toxic leachables.

What’s included in USP Class VI testing?

.Systemic injection tests in animals

.Intracutaneous (skin) tests

.Implantation tests over time

This certification is often required by OEMs for components used in implants, tubing, valves, and drug delivery systems.

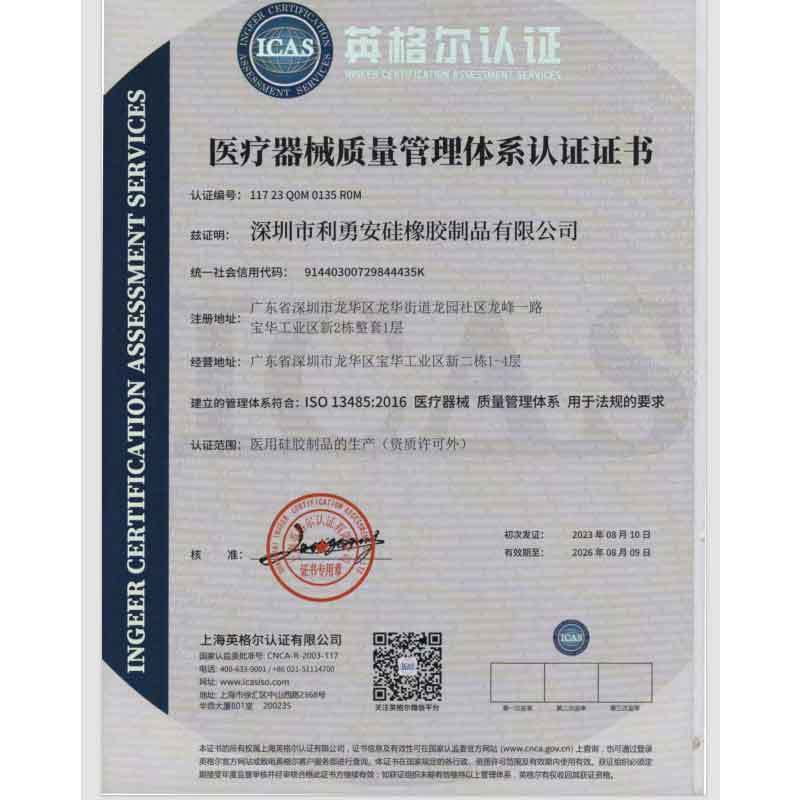

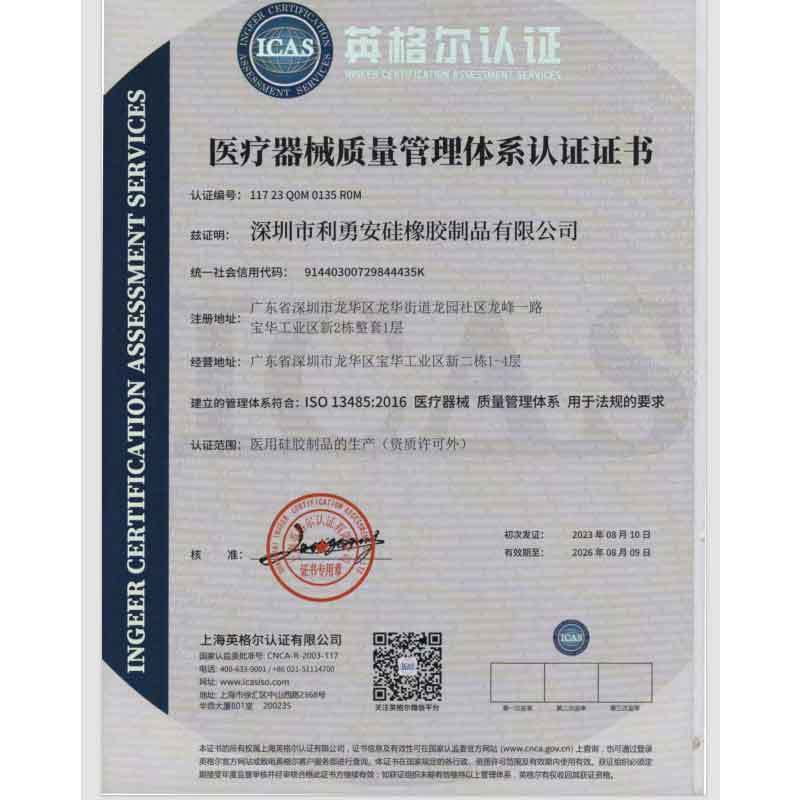

Is ISO 13485 certification mandatory for manufacturers?

Not for the material itself—but critical for the company that makes the part.

ISO 13485 certifies that the manufacturer follows medical-grade quality management practices throughout production.

Dive Deeper

A silicone component is only as reliable as the system that produced it. ISO 13485 ensures traceability, consistency, and risk management throughout the supply chain.

Key Benefits:

Documented quality control processes

Regulatory compliance for FDA and EU MDR

Fewer production errors and product recalls

Required for most medtech clients and audits

If you're sourcing silicone components for medical use, always ask: is the supplier ISO 13485 certified?

Are there other important regional or application-specific certifications?

Yes—especially when entering global markets.

CE marking in Europe, FDA 21 CFR compliance in the U.S., and REACH/RoHS in electronics may also apply depending on the end use.

Dive Deeper

Other Certifications to Consider:

| Certification | Relevance |

| FDA 21 CFR Part 177 | U.S. compliance for food and medical-grade silicone |

| CE Marking | Required for devices sold in the EU |

REACH & RoHS | Important for electronics + silicone overmolding |

| ISO 14644 | Cleanroom production certification |

The right certifications depend on the device class, region, and functionality.

Conclusion

Certified silicone ensures patient safety, global compliance, and product credibility.