What are the application scenarios of silicone in automotive parts?

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- Jan 8,2025

Summary

Silicone enhances automotive parts with heat resistance, sealing, insulation, and durability. It’s widely used in seals, gaskets, hoses, electronics, and even automotive paint protection.

Silicone is a material widely used in automotive parts, thanks to its unique properties like heat resistance, flexibility, and durability. But what specific roles does silicone play in modern cars?

Silicone is used in automotive parts for sealing, insulation, durability, and improving performance in extreme conditions, making it a versatile material for the industry.

Its applications extend from improving vehicle safety to enhancing performance and aesthetics. Let’s dive deeper into how silicone contributes to the automotive industry.

[Table of Contents]

What are the applications of silicone rubber in automotive?

What are the applications of silicones?

What is silicone used for in a car?

What does silicone do to automotive paint?

What are the applications of silicone rubber in automotive?

Silicone rubber has revolutionized the automotive industry. But where exactly is it used?

Silicone rubber is used in automotive seals, gaskets, hoses, and insulating materials due to its heat resistance, flexibility, and durability.

Dive Deeper: Key Areas Where Silicone Rubber Shines

Silicone rubber stands out because of its ability to perform under extreme conditions, from high temperatures to harsh chemicals. This makes it an ideal choice for critical automotive components.

Applications of Silicone Rubber in Automotive:

Sealing and Gaskets: Silicone rubber is used for engine gaskets, valve covers, and oil seals. It prevents leaks and ensures the engine operates smoothly.

Hoses: Silicone hoses handle high-pressure and high-temperature fluids, making them crucial for turbochargers, radiators, and fuel systems.

Electrical Insulation: Silicone rubber insulates wires and cables, protecting them from heat and moisture.

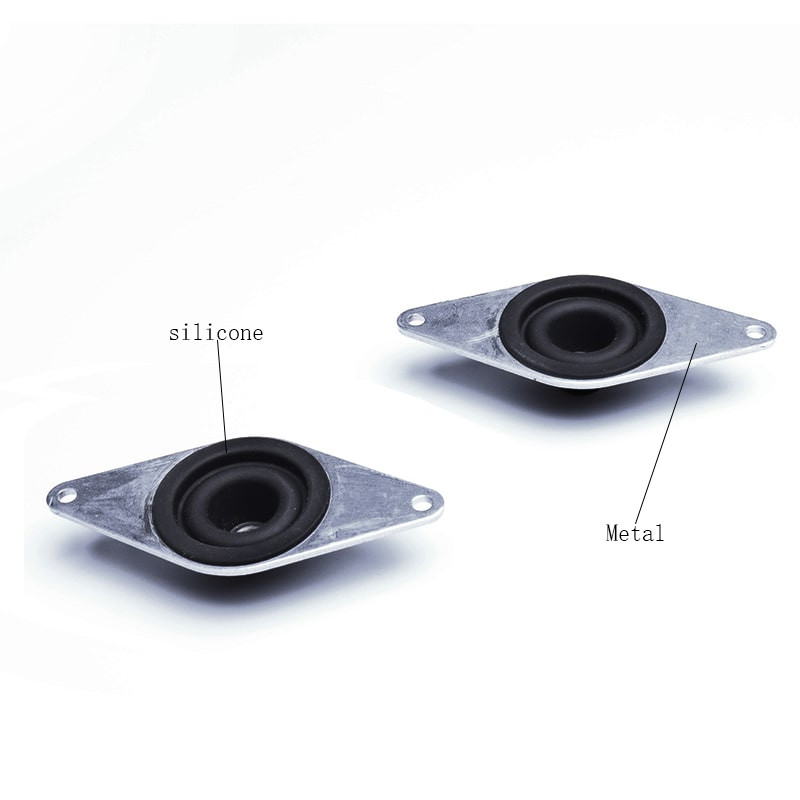

Vibration Dampening: Used in mounts and bushings to reduce engine noise and vibrations.

With its versatility, silicone rubber enhances the longevity and efficiency of automotive parts, ensuring vehicles remain safe and reliable.

What are the applications of silicones?

Silicones are not limited to rubber forms; they come in various types like adhesives, lubricants, and coatings. But how do these other forms serve the automotive industry?

Silicones are used as adhesives, sealants, lubricants, and protective coatings to enhance durability and performance in automotive systems.

Dive Deeper: Exploring Silicones Beyond Rubber

Silicones in their non-rubber forms bring value to areas where flexibility, water resistance, and heat tolerance are key.

Popular Silicone Applications in Automotive:

Adhesives and Sealants: Used for windshield installation, bonding body panels, and sealing gaps in car interiors.

Lubricants: Silicone lubricants reduce friction in moving parts, such as door hinges and window mechanisms.

Protective Coatings: Used on electrical parts to shield against moisture, corrosion, and extreme weather.

| Silicone Application | Automotive Use Case |

| Adhesives/Sealants | Windshields, panel bonding |

| Lubricants | Door hinges, sliding windows |

| Coatings | Moisture protection, corrosion prevention |

These applications highlight how silicones support both the functional and aesthetic aspects of automotive systems.

Conclusion

Silicone plays a critical role in the automotive industry, enhancing performance, durability, and aesthetics across various components. While it offers numerous benefits, addressing challenges like recycling and compatibility with other materials ensures its sustainable and effective use in automotive applications.