Transform Your Molding Process with Medical Grade Silicone

- Share

- publisher

- siliconeplus

- Issue Time

- Jul 29,2025

Summary

Medical grade silicone offers unmatched biocompatibility, durability, and precision for molding medical devices—boosting safety, compliance, and production efficiency in healthcare manufacturing.

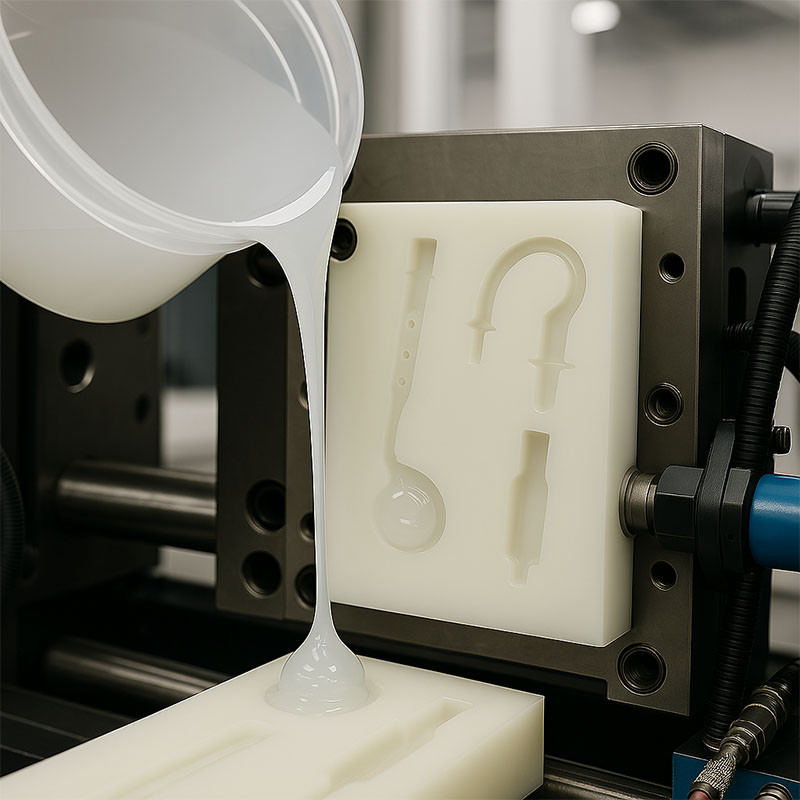

Transform Your Molding Process with Medical Grade Silicone

In the competitive landscape of modern manufacturing, especially within the medical industry, the choice of materials directly influences product quality, safety, and efficacy. Among these, medical grade silicone has emerged as the gold standard for achieving superior results in molding processes. Our comprehensive guide explores how integrating medical grade silicone into your manufacturing workflow can dramatically enhance your product outcomes, streamline production, and ensure compliance with rigorous regulatory standards.

The Ultimate Advantages of Medical Grade Silicone in Molding

Unmatched Biocompatibility and Safety

Medical grade silicone is renowned for its exceptional biocompatibility, making it the material of choice for implants, prosthetics, and other medical devices that require direct contact with human tissue. Its inert nature minimizes risks of allergic reactions, irritation, or toxicity, ensuring patient safety and regulatory compliance.

Superior Durability and Flexibility

Unlike traditional plastics or rubbers, medical silicone exhibits outstanding temperature resistance, chemical stability, and mechanical resilience. This combination guarantees long-lasting molds and products that withstand repeated sterilization cycles without degradation, maintaining consistent performance over time.

Precision and Detail Reproduction

The flow properties of medical grade silicone enable high-fidelity moldings, capturing intricate details with minimal shrinkage or distortion. This precision is critical for complex medical components where tolerances are tight and quality is paramount.

Ease of Processing and Versatility

Medical silicone can be processed through various molding techniques, including compression, injection, and transfer molding. Its adaptability allows manufacturers to produce a wide range of medical devices, from soft implants to detailed prototypes, with minimal tooling modifications.

Optimizing Your Molding Workflow with Medical Grade Silicone

Selecting the Right Silicone Formulation

The foundation of an efficient molding process begins with choosing the appropriate medical silicone formulation. Factors to consider include:

- Viscosity: To ensure smooth flow into fine details.

- Cure System: Addition-cure (platinum-cure) silicones offer superior clarity and biocompatibility.

- Tensile Strength and Elongation: For flexible, durable products.

- Temperature Resistance: To withstand sterilization cycles.

Designing Molds for Medical Grade Silicone

Design considerations must prioritize ease of demolding, minimal surface defects, and dimensional accuracy. Incorporate features like venting channels to prevent air entrapment and draft angles to facilitate removal. Use high-quality tooling made from materials compatible with silicone to prolong mold life.

Processing Techniques for Optimal Results

- Injection Molding: Ideal for high-volume production with consistent quality.

- Compression Molding: Suitable for prototypes or small batches.

- Transfer Molding: Combines advantages of both processes, offering detailed reproduction.

Consistent temperature control and pressure regulation are vital to achieving uniform curing and preventing defects such as voids or surface imperfections.

Ensuring Quality and Regulatory Compliance

Rigorous Testing and Certification

Medical silicone materials must adhere to strict standards such as ISO 10993, USP Class VI, and FDA approval. Implement comprehensive testing protocols covering cytotoxicity, leachables, sterilization compatibility, and long-term stability.

Sterilization Compatibility

Medical grade silicone withstands various sterilization methods, including steam autoclaving, ethylene oxide (EO), and gamma radiation. Selecting silicone formulations compatible with your sterilization process ensures maintained integrity and safety.

Traceability and Documentation

Maintain detailed records of material batches, processing parameters, and test results to facilitate regulatory audits and quality assurance.

Advanced Applications of Medical Grade Silicone Molding

| Application Area | Description | Key Benefits |

|---|---|---|

| Implants & Prosthetics | Soft, biocompatible components that mimic natural tissue | Comfort, safety, durability |

| Medical Tubing & Seals | Flexible, sterilizable seals for devices | Leak-proof, long-lasting |

| Diagnostic Devices | Precise, detailed molds for sensors and testing equipment | Accuracy, repeatability |

| Wearable Medical Devices | Soft, skin-friendly materials for comfort | User compliance, safety |

| Custom Medical Models & Prototypes | High-fidelity replicas for surgical planning | Accuracy, educational value |

[Insert Image: Medical silicone used in a prosthetic limb prototype]

Key Considerations for Manufacturing with Medical Grade Silicone

Material Handling and Storage

Proper storage in sealed, temperature-controlled environments preserves silicone’s properties. Avoid exposure to UV light, moisture, or contamination that could compromise material integrity.

Equipment Compatibility

Ensure your molding equipment is compatible with medical silicone in terms of temperature ranges, pressure capacities, and chemical resistance. Regular maintenance prevents contamination and ensures consistent output.

Post-Molding Processing

Post-curing at specified temperatures enhances the mechanical and chemical stability of silicone parts. Surface treatments, such as plasma or corona treatment, can improve adhesion or surface properties as needed.

Future Trends in Medical Silicone Molding

Smart Silicone Materials

Emerging smart silicones with embedded sensors or antimicrobial properties are expanding the horizons of medical device design, enabling real-time monitoring and infection control.

Additive Manufacturing with Silicone

Advances in silicone 3D printing are enabling rapid prototyping and small-batch production, reducing lead times and costs while maintaining high fidelity.

Sustainable and Eco-Friendly Silicone Alternatives

Research into biodegradable or recyclable silicones aims to reduce environmental impact, aligning medical manufacturing with sustainable practices.

Conclusion: Elevate Your Medical Manufacturing with Premium Silicone Solutions

Transforming your molding process with medical grade silicone is a strategic move toward achieving superior product quality, safety, and efficiency. Its unmatched biocompatibility, durability, and process versatility make it indispensable for the most demanding medical applications. By adopting cutting-edge techniques, rigorous quality control, and innovative formulations, manufacturers can position themselves at the forefront of medical device innovation.

Harness the power of medical grade silicone today—revolutionize your manufacturing, ensure patient safety, and set new standards of excellence in medical device production.