Top 5 Benefits of Silicone Overmolding on Metal Components

- Share

- publisher

- siliconeplus

- Issue Time

- Oct 24,2025

Summary

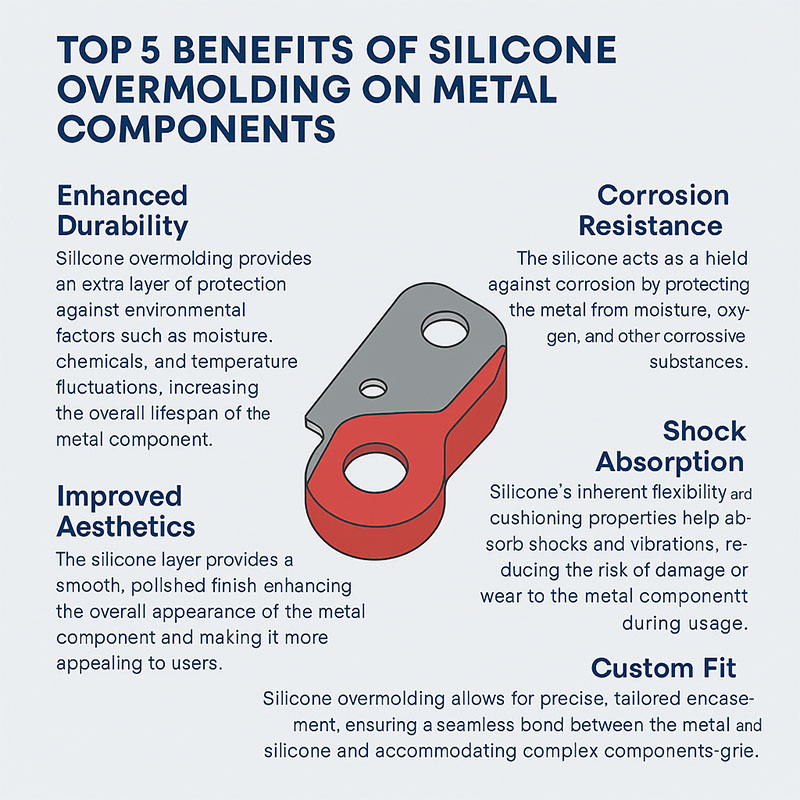

Top 5 Benefits of Silicone Overmolding on Metal: thermal resistance, vibration damping, durability, and superior design.

Introduction:

Silicone overmolding on metal components has revolutionized the manufacturing and engineering sectors by offering unparalleled advantages that enhance product performance, durability, and safety. As industry leaders committed to innovation, we recognize the importance of integrating advanced materials like silicone into metal parts to meet the rigorous demands of modern applications. Below, we explore the top five benefits of silicone overmolding on metal components, supported by detailed insights and technical advantages that position this technology as essential in high-performance manufacturing.

1. Superior Thermal Resistance and Temperature Stability

Silicone overmolding provides exceptional thermal stability, allowing metal components to operate reliably across a broad temperature spectrum, typically from -60°C to +230°C, with some formulations enduring even higher temperatures. This high-temperature resilience makes silicone an ideal overmolding material for applications exposed to extreme heat, such as automotive engine parts, electronic enclosures, and industrial machinery.

The silicone rubber's low thermal conductivity acts as an insulator, protecting sensitive electronic components from heat transfer and preventing overheating. This thermal barrier enhances product lifespan and operational safety, especially in environments where temperature fluctuations are frequent and intense. Additionally, silicone's ability to maintain its flexibility and elasticity at elevated temperatures ensures that overmolded parts do not crack or degrade, preserving structural integrity over extended periods.

2. Exceptional Electrical Insulation and Waterproofing Capabilities

Electrical insulation is critical in many industries, including aerospace, automotive, and electronics. Silicone overmolding provides outstanding dielectric properties, ensuring that metal components are effectively insulated against electrical currents, preventing shorts, leaks, and electrical failures.

Furthermore, silicone's waterproofing capabilities are unmatched. When applied as an overmold, it creates a robust, seamless barrier that resists moisture ingress, corrosion, and environmental contaminants. This waterproof seal is essential for outdoor and submerged applications, such as marine electronics, sensor housings, and lighting fixtures.

The combination of electrical insulation and waterproofing significantly reduces maintenance costs, enhances safety, and extends the service life of critical components in harsh environments.

3. Enhanced Mechanical Damping and Vibration Absorption

Vibration damping is vital in reducing wear and tear on mechanical systems, especially in automotive, aerospace, and precision instrumentation. Silicone's elasticity and compressibility enable it to absorb shocks and vibrations effectively when used as an overmold on metal components.

This damping capability minimizes fatigue and prevents microcracks that could develop over time due to constant mechanical stress. It also reduces noise levels, contributing to a quieter operation, which is particularly advantageous in consumer electronics and office equipment.

By incorporating silicone overmolding, manufacturers can improve overall system reliability and enhance user experience through smoother, quieter operations with reduced maintenance needs.

4. Outstanding Chemical and Environmental Resistance

Chemical exposure and environmental factors—such as UV radiation, ozone, oils, and solvents—pose significant challenges to metal components. Silicone overmolding offers superior chemical resistance, effectively protecting metal parts from corrosion, oxidation, and degradation caused by harsh substances.

This resistance is crucial in industries like chemical processing, oil and gas, and outdoor electrical systems, where components are exposed to aggressive chemicals or weather conditions. Silicone's UV stability ensures that the overmolded parts retain their properties even after prolonged exposure to sunlight, preventing cracking, discoloration, or loss of protective qualities.

Furthermore, silicone's non-reactive nature ensures that it does not degrade or leach harmful substances into the environment, aligning with eco-friendly manufacturing standards and regulatory compliance.

5. Improved Aesthetics and Ergonomics

Beyond technical performance, silicone overmolding significantly enhances the visual appeal and ergonomic features of metal components. The smooth, soft-touch surface of silicone provides a comfortable grip and sophisticated appearance, which is particularly desirable in consumer-facing products such as handheld devices, power tools, and medical equipment.

The overmolding process allows for precise color matching, branding, and design customization, enabling manufacturers to create visually distinctive products that stand out in competitive markets. Additionally, silicone's flexibility facilitates the creation of contoured shapes and integrated features that improve user interaction and product handling.

This aesthetic and ergonomic enhancement not only boosts brand perception but also improves user safety by reducing slips and providing better tactile feedback.

Conclusion: Why Silicone Overmolding on Metal Components Is the Future of High-Performance Manufacturing

In an era where durability, safety, and performance are paramount, silicone overmolding on metal components emerges as an indispensable technology. Its thermal stability, electrical insulation, vibration damping, chemical resistance, and aesthetic versatility collectively provide unmatched advantages that elevate product quality and reliability.

As industry standards continue to evolve, integrating silicone overmolding into manufacturing processes ensures that products are more resilient, long-lasting, and better suited to demanding environments. Whether in automotive, aerospace, medical, or consumer electronics, silicone overmolding is shaping the future of innovative, robust, and safety-driven component design.

Embrace the transformative potential of silicone overmolding to redefine your product offerings and set new benchmarks in engineering excellence. Our solutions guarantee that your metal components will perform flawlessly, regardless of environmental challenges or operational stresses.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883