The Ultimate Guide to Liquid Silicone Rubber (LSR) Material You Must Know

- Share

- publisher

- siliconeplus

- Issue Time

- Sep 6,2025

Summary

Comprehensive guide to Liquid Silicone Rubber (LSR): properties,applications, advantages, and choosing the right material.

The Ultimate Guide to Liquid Silicone Rubber (LSR) Material You Must Know

Liquid Silicone Rubber (LSR) has revolutionized the manufacturing industry with its exceptional versatility, durability, and performance. As a high-end material, LSR is increasingly favored across diverse sectors, including medical devices, automotive components, consumer electronics, and household appliances. This comprehensive guide delves into every aspect of Liquid Silicone Rubber, providing in-depth insights that empower manufacturers, engineers, and product designers to leverage its full potential.

What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber (LSR) is a high-performance elastomer characterized by its liquid form during processing, which is then cured into a solid, rubber-like material. Unlike traditional solid silicones, LSR is injected into molds through an advanced liquid injection molding (LIM) process, enabling precise, high-volume production of complex, detailed parts.

Key Characteristics of LSR:

Excellent thermal stability (operates from -55°C to +300°C)

Superior chemical resistance against oils, solvents, and UV light

Outstanding electrical insulation properties

Biocompatibility, making it ideal for medical applications

High transparency and colorability

Low compression set, ensuring long-term elasticity

The Composition and Types of Liquid Silicone Rubber

LSR is primarily composed of polydimethylsiloxane (PDMS), cross-linked with vinyl groups and hydrogen atoms during vulcanization. The precise formulation can be adjusted to optimize properties such as hardness, elasticity, and clarity.

Main Types of LSR:

| Type | Description | Typical Usage | Features |

| Standard LSR | General-purpose, versatile | Consumer electronics, household items | Good flexibility, clarity |

| High-Temperature LSR | Designed for extreme heat | Automotive, industrial equipment | Superior heat resistance |

| Medical Grade LSR | Biocompatible, sterilizable | Medical implants, sensors | Meets strict biocompatibility standards |

Food-Grade LSR | Safe for contact with food | Kitchenware, baby products | FDA compliant, non-toxic |

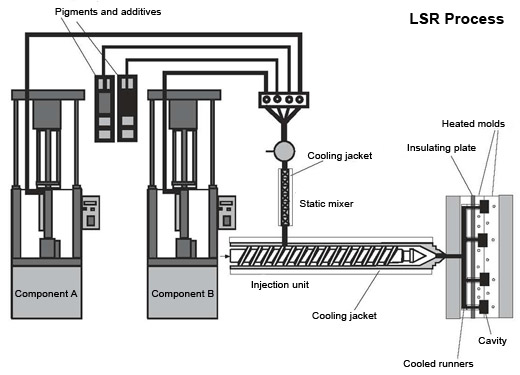

Manufacturing Process of Liquid Silicone Rubber

The production of LSR involves liquid injection molding (LIM), a highly efficient and precise process that offers numerous advantages over traditional rubber molding techniques.

Step-by-Step Process:

Material Preparation:

Raw LSR components are mixed and heated to a liquid state.

Injection Molding:

The liquid LSR is injected under high pressure into a pre-designed mold cavity.

Curing:

The mold is heated (typically between 150°C and 200°C), causing the vinyl groups to cross-link, transforming the liquid into a solid elastomer.

Ejection & Finishing:

The cured part is ejected, and further finishing processes such as trimming or surface treatment are performed.

Advantages of Liquid Silicone Rubber Over Traditional Elastomers

LSR presents multiple advantages that make it the material of choice for high-performance applications:

Superior Precision and Detail:

Its ability to capture intricate designs makes LSR ideal for micro-sized components and complex geometries.

Enhanced Durability:

Resistance to extreme temperatures, chemicals, and UV ensures longevity and reliability.

Biocompatibility and Safety:

Medical-grade LSR complies with stringent safety standards, enabling its use in sensitive medical devices.

Efficiency in Manufacturing:

The liquid injection molding process allows for mass production with consistent quality and reduced lead times.

Design Flexibility:

LSR can be formulated to vary in hardness, transparency, and color, offering extensive customization options.

Applications of Liquid Silicone Rubber (LSR)

LSR's unique properties open doors to a broad spectrum of industries and applications.

Medical Industry:

Implantable devices

Wearable sensors

Sterilizable seals and gaskets

Automotive Sector:

Lighting components

Vibration dampers

Electrical connectors

Consumer Electronics:

Wearable device casings

Keypads and buttons

Household and Kitchenware:

Silicone bakeware and molds

Kitchen utensils

Baby bottle nipples

Waterproof seals

Industrial Applications:

O-rings and seals

Electrical insulation components

Sensor housings

Choosing the Right LSR for Your Application

Selecting the optimal LSR formulation involves considering multiple factors to meet specific performance criteria.

Key Considerations:

| Criterion | Importance | Recommendations |

Hardness (Shore A) | Determines flexibility and stiffness | Match application needs; softer for seals, harder for structural parts |

Temperature Range | Operational environment | Use high-temperature LSR for automotive or industrial use |

| Biocompatibility | Medical or food contact | Select FDA-compliant, medical-grade LSR |

| Chemical Resistance | Exposure to oils, solvents, or chemicals | Opt for specialized formulations with enhanced chemical resistance |

| Transparency/Colorability | Aesthetic requirements | Choose clear or pigmented formulations accordingly |

Supplier and Quality Assurance:

Partner with reputable LSR suppliers who provide certified, high-quality materials.

Verify compliance with international standards such as ISO 10993 (medical biocompatibility) and FDA regulations for food safety.

Conduct rigorous testing to ensure material consistency and performance stability.

Future Trends and Innovations in Liquid Silicone Rubber

The LSR industry is continually evolving, driven by technological advancements and expanding application demands.

Emerging Trends:

Nanocomposite LSRs: Incorporation of nanomaterials to enhance mechanical strength, thermal conductivity, and antimicrobial properties.

Smart Silicone Materials: Embedding sensors and responsive elements for wearable health devices and smart packaging.

Sustainable Manufacturing: Development of eco-friendly LSR formulations with reduced environmental impact.

3D Printing with LSR: Advancements in additive manufacturing techniques to create complex, customized parts rapidly.

Research and Development Focus:

Improving recycling and reusability of LSR waste.

Enhancing biodegradability for environmentally conscious products.

Expanding medical applications with advanced sterilization and biocompatibility features.

Conclusion: Unlocking the Full Potential of Liquid Silicone Rubber

Liquid Silicone Rubber (LSR) stands as a cornerstone material in modern manufacturing, offering unmatched versatility, durability, and safety. Its ability to be precisely molded into complex, high-quality components makes it indispensable across industries—from healthcare to automotive, consumer electronics, and household products.

By understanding the detailed properties, manufacturing processes, and application-specific considerations outlined in this guide, manufacturers and designers can make informed decisions that maximize product performance and innovation.

Investing in high-quality LSR materials and leveraging advanced processing techniques ensures a competitive edge in today's fast-paced, technology-driven market landscape.

Harness the power of Liquid Silicone Rubber—your gateway to next-generation, high-performance products.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883