The Ultimate Guide to Liquid Silicone Injection Molding in Consumer Electronics

- Share

- Issue Time

- Sep 26,2025

Summary

Discover how Liquid Silicone Rubber (LSR) injection molding is revolutionizing the consumer electronics industry. This guide explores the unparalleled benefits, advanced applications, and manufacturing precision that make LSR the go-to material for creating durable, high-performance, and innovative electronic devices, from wearables to smart home gadgets.

Why Liquid Silicone Rubber is a Game-Changer for Modern Electronics

In the fast-paced world of consumer electronics, manufacturers are in a constant race to create smaller, more durable, and more powerful devices. The choice of material is critical, and this is where Liquid Silicone Rubber (LSR) emerges as a superior solution. Processed through a high-precision method called Liquid Silicone Injection Molding (LIM), LSR offers a unique combination of properties that traditional materials like plastics and conventional rubbers cannot match. From the smartwatch on your wrist to the intricate seals inside your smartphone, LSR is enhancing performance, longevity, and user experience.

This guide will delve deep into the world of liquid silicone injection molding, exploring why this technology is not just an alternative but a necessary evolution for producing next-generation consumer electronics.

Understanding Liquid Silicone Rubber (LSR)

Liquid Silicone Rubber is a high-purity, two-part platinum-cured elastomer that starts as a liquid and is cured into a solid, flexible part through heat. Unlike other materials, its liquid state allows it to be pumped through pipelines and injected into highly complex molds to create parts with extreme precision and detail. This process, known as liquid injection molding (LIM), is highly automated and allows for rapid production cycles, making it ideal for the high-volume demands of the electronics market.

The Core Properties That Make LSR Ideal for Electronics

LSR’s popularity in the electronics sector is due to its remarkable combination of physical and chemical properties.

- Exceptional Durability: LSR is resistant to extreme temperatures, often from -60°C to over 200°C, as well as UV radiation and aging. This ensures components remain stable and functional over the product's lifespan.

- Biocompatibility: Being non-toxic and hypoallergenic, LSR is the perfect material for devices that have prolonged skin contact, such as wearable fitness trackers, smartwatch bands, and medical sensors.

- Superior Electrical Insulation: LSR has excellent dielectric properties, meaning it does not conduct electricity. This makes it a perfect insulator for protecting sensitive micro-electronics, wiring, and connectors from short circuits.

- Resistance to Water and Dust: The material is naturally hydrophobic (water-repellent), making it ideal for creating intricate seals and gaskets that give smartphones, chargers, and other gadgets high IP (Ingress Protection) ratings for water and dust resistance.

- Low Compression Set: LSR maintains its shape and sealing force even after long periods of compression, a critical feature for protective seals and buttons.

The Liquid Silicone Injection Molding (LIM) Process Explained

The LIM process is a cornerstone of LSR's utility in manufacturing. It is a highly precise and automated method that ensures consistency and quality.

- Material Preparation: Two liquid components (A and B) are precisely mixed in a 1:1 ratio. Colorants or other additives can be introduced at this stage.

- Injection: The mixed LSR is injected under high pressure into a pre-heated, precision-engineered mold cavity. The low viscosity of the material allows it to fill even the most intricate and thin-walled sections of the mold.

- Curing: The heat from the mold initiates a rapid curing process, cross-linking the material and turning it from a liquid into a solid rubber part in a matter of seconds.

- Demolding: Once cured, the part is ejected or manually removed. Due to LSR's flexibility, even parts with complex undercuts can be removed easily. The cycle time is very short, enabling high-volume production.

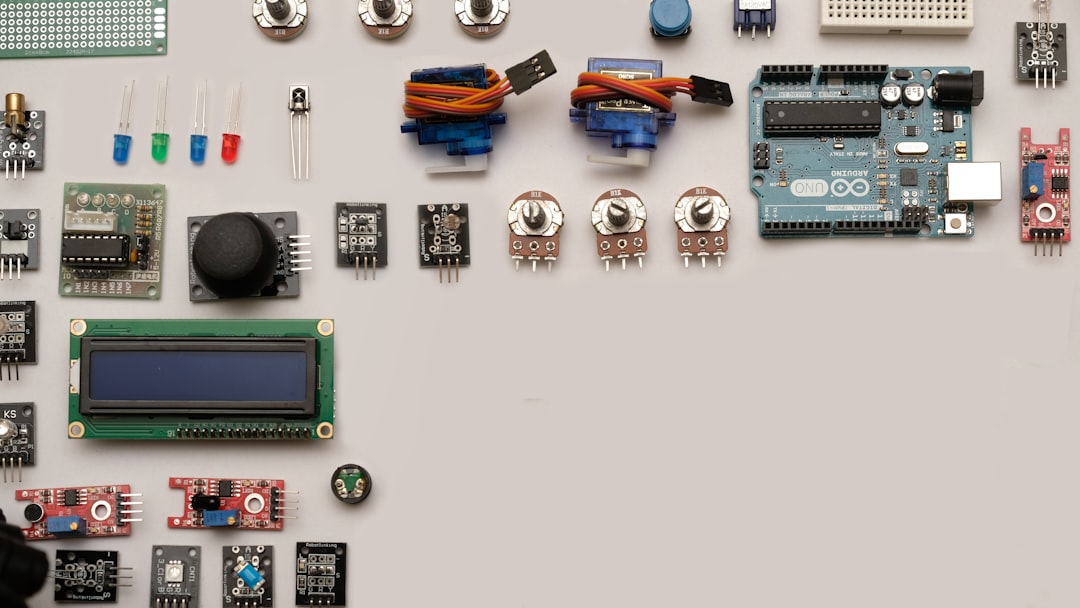

Key Applications in Consumer Electronics

The versatility of LSR has led to its adoption across a wide spectrum of electronic devices.

- Wearable Technology: This is a primary market for LSR. It's used for smartwatch and fitness tracker bands, sensor housings, and soft, flexible covers that are durable, sweat-resistant, and comfortable.

- Smartphones and Mobile Devices: LSR is critical for creating the tiny, complex waterproof seals around SIM card trays, charging ports, and buttons. It's also used for shock-absorbing dampers that protect internal components from drops.

- Audio Equipment: In headphones and earbuds, LSR is used to create soft, comfortable, and durable ear tips. Its vibration-damping properties can also improve acoustic performance by insulating speakers.

- Keypads and Buttons: The soft, tactile feel of LSR makes it perfect for buttons and keypads that need to withstand millions of presses without degrading. Overmolding allows LSR to be bonded directly onto plastic or metal substrates.

- Connectors and Cabling: LSR's excellent insulation and heat resistance make it ideal for connector seals, cable strain reliefs, and protective sleeving for wires.

Overmolding and 2K Molding: Integrating LSR with Other Materials

One of the most significant advantages of liquid silicone injection molding is its ability to be used in overmolding (also known as 2K molding). This process involves molding LSR directly onto a substrate made of another material, such as plastic or metal. This creates a powerful, seamless bond without the need for adhesive primers. For consumer electronics, this is used to:

- Create water-tight seals directly on plastic housings.

- Mold soft-touch grips onto hard plastic handles or cases.

- Encapsulate sensitive electronic components for complete protection from shock, vibration, and moisture.

The Advantage of Precision: Micro-Molding with LSR

As electronics relentlessly shrink in size, the demand for microscopic components grows. LSR injection molding excels at micro-molding, producing parts with features measured in microns. This capability is essential for creating micro-seals, tiny connectors, and precise dampers required in today's compact devices. The low viscosity of liquid silicone allows it to perfectly replicate these microscopic mold details, a feat that is difficult with thicker materials.

LSR vs. Other Materials: A Comparative Look

To understand why LSR is a superior choice, it's helpful to compare it to other common materials used in electronics.

| Feature | Liquid Silicone Rubber (LSR) | Thermoplastic Elastomers (TPE) | Natural Rubber |

|---|---|---|---|

| Temperature Resistance | Excellent (-60°C to 200°C+) | Moderate | Poor |

| UV Resistance | Excellent | Poor to Moderate | Poor |

| Biocompatibility | Excellent (Medical Grade) | Varies (Additives can be an issue) | Can cause allergies |

| Sealing (Compression Set) | Excellent (Low compression set) | Good | Fair |

| Processing Precision | Excellent (Micro-features) | Good | Poor |

| Chemical Resistance | Excellent | Good | Poor |

Enhancing Device Durability and Lifespan

Durability is a major selling point for consumer electronics. Liquid silicone injection molding contributes significantly to a product's robustness. Components made from LSR provide superior protection against drops, impacts, and environmental stressors. Sealing out water and dust prevents the two most common causes of electronic failure, directly extending the lifespan and reliability of a device and reducing warranty claims for manufacturers.

Sustainability and Manufacturing Efficiency

Sustainability is an increasingly important factor in manufacturing. The LSR injection molding process is highly efficient, producing minimal waste. Unlike thermoplastic injection molding, there are no sprues or runners that need to be discarded or reground. The automated, rapid-curing process also consumes less energy per part compared to other molding methods. LSR itself is a durable material, which means products last longer and need to be replaced less frequently, contributing to a more sustainable consumption cycle.

Future Outlook: The Expanding Role of LSR Injection Molding

The future of consumer electronics points towards even greater integration of technology into our lives, with trends like the Internet of Things (IoT), flexible electronics, and augmented reality. Liquid silicone rubber is perfectly positioned to support these innovations.

- Flexible and Bendable Devices: LSR's inherent flexibility makes it a key enabler for creating foldable phones and rollable displays.

- Miniaturization: As devices get smaller, the need for micro-molded LSR parts will only increase.

- Integrated Smart Systems: LSR's ability to encapsulate electronics will be vital for creating smart textiles, integrated health monitors, and other IoT devices where electronics are seamlessly embedded into everyday objects.

Conclusion: The Clear Choice for High-Performance Electronics

Liquid silicone injection molding is far more than just a manufacturing process; it is a critical enabler of innovation in the consumer electronics industry. Its ability to produce highly precise, durable, and biocompatible components at scale makes it the go-to solution for tackling modern engineering challenges. By offering superior protection, enhanced user experience, and design freedom, LSR empowers manufacturers to build the reliable, feature-rich electronic devices that consumers demand.