The Top Trends in Custom Silicone Product Design for 2025

- Share

- publisher

- siliconeplus

- Issue Time

- Oct 8,2025

Summary

Custom silicone design in 2025 focuses on personalization, sustainability, smart tech, and precision innovation.

Introduction

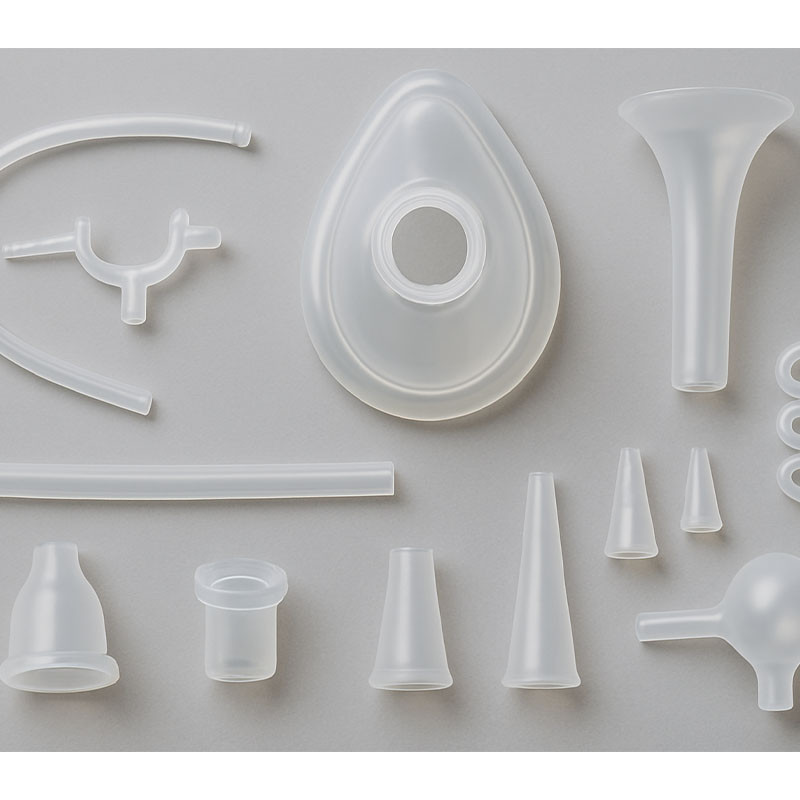

In an increasingly competitive marketplace, custom silicone product design continues to evolve at a rapid pace, driven by technological advancements, consumer demand for sustainable solutions, and innovative applications across industries. As experts in silicone manufacturing, we are committed to staying ahead of the curve by leveraging the latest trends that define 2025’s landscape. This comprehensive guide explores the most influential trends shaping custom silicone products, providing insights into materials, design techniques, sustainability, and emerging applications that will dominate this year.

Unparalleled Customization and Personalization in Silicone Products

Increasing Demand for Tailored Silicone Solutions

In 2025, personalization remains a cornerstone of custom silicone product design. Consumers are seeking products that reflect their individual preferences, lifestyles, and identities. From customized phone cases to personalized silicone wristbands, brands that offer tailored solutions gain a competitive edge.

Advanced Mold Technologies Enable Precision Customization

The advent of high-precision 3D printing and CNC molding has revolutionized the ability to produce intricately detailed silicone designs. These technologies allow for complex textures, unique patterns, and multi-color integrations that were previously impossible, enabling brands to create truly bespoke silicone products that stand out in the marketplace.

Sustainable and Eco-Friendly Silicone Innovations

Eco-Conscious Materials and Manufacturing Processes

Sustainability is no longer optional; it’s essential. In 2024, eco-friendly silicone formulations are gaining prominence. These formulations utilize bio-based raw materials and recyclable silicone that reduce environmental impact without sacrificing quality or durability.

Recyclability and Reuse of Silicone Products

Innovative recycling techniques now allow for post-consumer silicone to be reclaimed and repurposed into new products. Companies are adopting closed-loop manufacturing systems that promote circular economy principles, aligning with consumer expectations for environmentally responsible products.

Biodegradable Silicone Alternatives

Research into biodegradable silicone is accelerating, aiming to develop products that break down naturally after disposal. While still in experimental stages, these materials are poised to revolutionize sustainable silicone product design by offering eco-friendly alternatives that do not compromise on performance.

Integration of Smart Technologies in Silicone Products

Smart Silicone for Wearables and IoT Devices

The integration of smart technology into silicone products is a major trend. Smart silicone incorporates embedded sensors and connectivity modules, transforming everyday items like wearable health monitors, smart grips, and interactive toys into connected devices.

Innovative Manufacturing Techniques and Material Enhancements

Silicone Injection Molding and Rapid Prototyping

Modern injection molding techniques, combined with rapid prototyping, significantly reduce production cycles and costs. These methods facilitate quick iterations, allowing designers to refine their custom silicone products efficiently and accurately.

Multi-Layer and Multi-Color Silicone Designs

The ability to produce multi-layered and multi-color silicone products enhances aesthetic appeal and functional differentiation. This trend is especially prominent in luxury consumer goods, medical devices, and branding products where visual impact is critical.

Enhanced Durability and Temperature Resistance

New formulations of high-performance silicone materials offer superior durability, chemical resistance, and temperature tolerance. These enhancements extend product lifespan and expand application possibilities, especially in harsh environments.

Emerging Applications Across Industries

Custom silicone is revolutionizing medical applications with biocompatible, hypoallergenic, and sterilizable materials. Innovations include implantable devices, medical seals, and personal protective equipment tailored to individual patient needs.

Consumer Electronics and Wearables

Silicone's flexibility, durability, and aesthetic versatility make it ideal for smartphone accessories, wearable gadgets, and gaming peripherals. Custom designs incorporate branding elements, ergonomic features, and sensor integration.

Automotive and Transportation

The automotive industry leverages custom silicone components for seals, gaskets, and interior trim that withstand extreme temperatures and chemical exposure. The trend toward luxury interiors has increased demand for colorful, textured silicone accents.

Fashion and Lifestyle Accessories

From silicone jewelry to fashionable watch bands, designers are embracing bold colors, unique shapes, and textured finishes to create products that are both functional and stylish.

Design Flexibility and Aesthetic Innovation

Textured and Patterned Silicone Surfaces

Innovative surface treatments enable silicone products to feature embossed patterns, matte finishes, or glossy textures. These enhancements improve grip, visual appeal, and tactile experience, making products more engaging.

Translucent and Opaque Color Effects

The ability to blend translucent, opaque, and semi-transparent silicone allows designers to create layered visual effects and color gradients. This flexibility is especially valued in luxury branding and artistic applications.

Embedded Logos and Custom Graphics

Advanced manufacturing techniques facilitate the embedding of logos, text, and custom graphics directly into silicone products. This feature enhances brand visibility and product differentiation.

The Future of Custom Silicone Product Design

Hybrid Materials and Composite Silicone Products

The integration of silicone with other materials, such as metal, plastic, or fabric, opens new avenues for hybrid products that combine flexibility, strength, and aesthetic appeal. These composites expand the functional scope of silicone-based designs.

AI-Driven Design and Manufacturing Optimization

Artificial intelligence is increasingly used to optimize design parameters, predict manufacturing outcomes, and personalize products at scale. AI-driven tools enable more precise, cost-effective, and innovative silicone product development.

Customization at Scale with Digital Manufacturing

Digital manufacturing platforms enable mass customization, allowing brands to produce individualized silicone products efficiently. This trend aligns with the rise of on-demand production and personalized branding strategies.

Conclusion: Embracing Innovation in 2025

The landscape of custom silicone product design in 2024 is characterized by a convergence of technological innovation, sustainable practices, and creative aesthetics. Companies that harness these trends—embracing advanced manufacturing, eco-conscious materials, and smart functionalities—will position themselves at the forefront of the industry.

By focusing on personalization, environmental responsibility, and cutting-edge applications, brands can deliver unique, durable, and eco-friendly silicone products that meet the evolving demands of consumers worldwide. Staying ahead in this dynamic field requires a commitment to continuous innovation, quality craftsmanship, and sustainable development.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883