The Top 10 Custom Liquid Silicone Rubber Manufacturers for Medical Devices

- Share

- publisher

- siliconeplus

- Issue Time

- Oct 27,2025

Summary

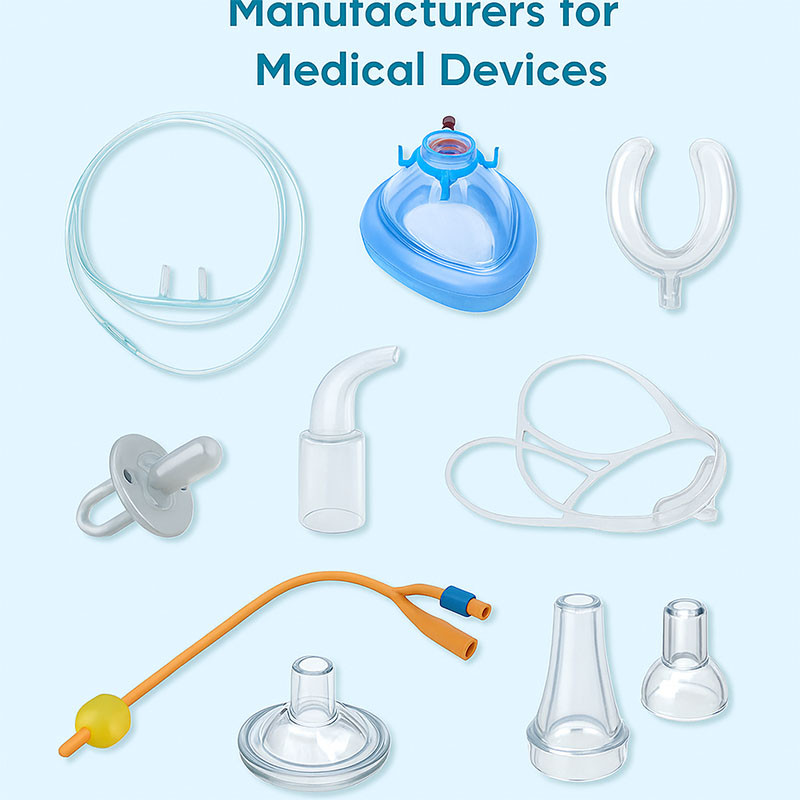

Top 10 Custom Liquid Silicone Rubber Manufacturers for Medical Devices Leading LSR Suppliers for Quality

Introduction:

In the highly regulated and demanding world of medical device manufacturing, the choice of liquid silicone rubber (LSR) suppliers is crucial. These manufacturers must consistently deliver high-quality, compliant, and innovative silicone materials tailored to the specific needs of medical applications. As industry leaders, we have meticulously analyzed the market, evaluating product quality, compliance standards, technological innovation, and customer service to identify the top 10 custom liquid silicone rubber manufacturers for medical devices.

Why Liquid Silicone Rubber is Critical in Medical Devices

Liquid Silicone Rubber (LSR) is renowned for its exceptional biocompatibility, flexibility, temperature resistance, and durability. These properties make it indispensable in the production of medical tubing, seals, implants, and wearable devices. The ability to customize LSR formulations ensures that manufacturers can meet stringent regulatory requirements such as ISO 10993, USP Class VI, and FDA compliance.

Key Criteria for Selecting Leading Medical Silicone Rubber Suppliers

Regulatory Compliance & Certifications: Ensuring ISO, FDA, and USP standards.

Customization Capabilities:

Precise formulation adjustments to meet specific medical application needs.Material Quality & Purity:

Use of medical-grade, biocompatible raw materials.Technological Innovation:

Advanced molding, curing, and processing techniques.Production Capacity & Scalability:

Ability to handle large-scale orders with consistent quality.Customer Support & Technical Assistance:

Dedicated engineering support and regulatory guidance.Leading Manufacturers of Custom Liquid Silicone Rubber for Medical Devices

1. Dow Corning (DOW Silicones)

Dow Corning Silicone

Dow Corning is a pioneer in silicone technology, offering an extensive portfolio of medical-grade LSR that meets the most stringent regulatory standards. Their customization services enable precise formulation adjustments for applications such as catheters, seals, and implantable devices. Their DOWSIL™ product line is renowned for its biocompatibility, clarity, and durability.

2. Wacker Chemie AG

Wacker Silicone

Wacker Chemie specializes in high-performance silicone elastomers tailored for medical applications. Their MED3 series offers custom formulations with excellent mechanical properties and biocompatibility, supporting complex medical device manufacturing processes. Their innovative curing techniques ensure precise dimensional stability.

3. Nusil Technology

Nusil Silicone

Nusil Technology is a leader in medical-grade silicone rubber development, providing custom LSR solutions that meet or exceed regulatory standards. Their Silbione™ series is favored for implantable devices, offering excellent chemical resistance and flexibility. Their dedicated R&D team supports clients with tailored formulations.

4. Momentive Performance Materials

Momentive Silicone

Momentive offers a comprehensive range of custom silicone rubbers designed specifically for medical device applications. Their Silopren™ series is known for biocompatibility, optical clarity, and mechanical strength, making them ideal for wearables, seals, and tubing.

5. WIT Silicone

WIT Silicone

WIT Silicone specializes in custom liquid silicone formulations for medical and healthcare applications. Their tailored solutions focus on biocompatibility, temperature resistance, and ease of processing, ensuring product consistency and regulatory compliance.

6. Shin-Etsu Chemical Co., Ltd.

Shin-Etsu Silicone

Shin-Etsu is a global leader in silicone materials, providing custom LSR formulations optimized for medical devices. Their high-purity silicones undergo rigorous quality control to meet medical standards, supporting both small-batch and large-scale production.

7. Bluestar Silicone

Bluestar Silicone

Bluestar Silicone offers tailored silicone solutions with excellent biocompatibility and chemical resistance. Their customizable formulations are used extensively in catheters, seals, and wearable health devices, backed by comprehensive regulatory support.

8. Chenguang Silicone

Chenguang Silicone

Chenguang Silicone specializes in custom liquid silicone rubber for medical and healthcare applications. Their R&D team ensures formulation flexibility to meet specific device requirements, emphasizing biocompatibility and processability.

9. Elkem Silicones

Elkem Silicone

Elkem Silicones provides medical-grade LSR with customization options tailored to implantable and non-implantable devices. Their advanced curing technologies support complex geometries and high-volume production.

Your Trusted Partner in Custom Liquid Silicone Rubber Solutions for Medical Devices

At Siliconeplus.net, we specialize in custom liquid silicone rubber (LSR) manufacturing for the medical and healthcare industry. With advanced molding technology, medical-grade materials, and strict quality control under ISO 13485 and FDA standards, we deliver safe, biocompatible, and high-performance silicone components.

From catheters, seals, and valves to wearable medical parts and diagnostic accessories, our expert R&D team provides tailored formulations to meet your unique requirements. We combine innovation, precision, and compliance — helping medical device brands achieve superior quality and reliability.

In-Depth Analysis of Customization Capabilities

| Manufacturer | Customization Strengths | Typical Applications | Regulatory Certifications |

Dow Corning | Extensive formulation options, high purity | Catheters, seals, implants | FDA, ISO 10993, USP Class VI |

Wacker | Mechanical property tuning, optical clarity | Wearables, tubing | ISO 13485, CE Mark |

| Nusil | Chemical resistance, biocompatibility | Implantable devices, prosthetics | USP Class VI, ISO 10993 |

| Momentive | Mechanical strength, transparency | Seals, flexible components | FDA, ISO 13485 |

| WIT | Temperature resistance, processability | Diagnostic devices, seals | CE, FDA |

Regulatory and Quality Assurance in Medical Silicone Rubber Manufacturing

Achieving regulatory compliance is non-negotiable in medical device manufacturing. The leading custom liquid silicone rubber manufacturers invest heavily in quality management systems, including ISO 13485 certification, FDA registration, and adherence to USP standards. They implement rigorous testing protocols such as extractables and leachables testing, cytotoxicity assessments, and long-term biostability studies.

Biocompatibility testing is conducted in accordance with ISO 10993, ensuring that LSR materials are safe for implantation or skin contact. Additionally, traceability systems guarantee that every batch of custom silicone can be tracked, ensuring product integrity and regulatory audit readiness.

Technological Innovations Shaping the Future of Medical Silicone Rubber

The top manufacturers continuously push the boundaries of material science and manufacturing technology:

Advanced Curing Technologies: Use of plasma, UV, and electron beam curing to improve mechanical properties and dimensional stability.

Nano-Modified Silicones:

Incorporation of nanoparticles to enhance antimicrobial properties and mechanical strength.Additive Manufacturing Compatibility:

Development of LSR formulations suitable for 3D printing, enabling rapid prototyping and customized device production.Smart Silicone Materials:

Integration of sensor capabilities within silicone matrices for smart medical devices.Conclusion: Partnering with the Best for Medical Device Success

Selecting the right partner among the top 10 custom liquid silicone rubber manufacturers is pivotal for medical device manufacturers aiming for innovation, regulatory compliance, and superior quality. These industry leaders offer tailored solutions that meet the stringent demands of medical applications, ensuring patient safety, device durability, and manufacturing efficiency.

By leveraging their technological expertise, regulatory support, and customization capabilities, companies can accelerate the development of cutting-edge medical devices that improve patient outcomes and market competitiveness.

Contact Us

For more detailed consultations, custom formulation requests, or regulatory assistance, contact our dedicated team of medical silicone rubber specialists. We are committed to delivering excellence in every batch, ensuring your medical devices meet the highest standards of quality and safety.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883