The Future of Silicone Medical Products: Trends to Watch

- Share

- publisher

- siliconeplus

- Issue Time

- Jul 9,2025

Summary

Silicone medical products are evolving with smart materials, antimicrobial properties, 3D printing, and sustainable production, driving safer, more personalized, and eco-friendly healthcare solutions

The Future of Silicone Medical Products: Trends to Watch

Introduction: The Rising Significance of Silicone in Medical Applications

Silicone has become an indispensable material in the medical industry, celebrated for its biocompatibility, flexibility, durability, and resistance to extreme conditions. As healthcare demands evolve, so does the innovation surrounding silicone-based medical devices and implants. The future of silicone medical products is poised for transformative growth driven by technological advancements, regulatory developments, and a deeper understanding of material sciences. This comprehensive exploration delineates the critical trends shaping the evolution of silicone in medical applications, highlighting how these trends will redefine patient care and device performance.

Advancements in Silicone Material Technologies

Enhanced Biocompatibility and Safety Profiles

The core advantage of silicone in medical applications is its exceptional biocompatibility, minimizing adverse reactions and ensuring patient safety. Future innovations focus on refining silicone formulations to further reduce the risk of allergic reactions or toxicity. Researchers are developing medical-grade silicones with improved purity and specialized surface modifications to promote tissue integration and reduce bacterial adhesion, thereby lowering infection risks.

Silicone with Antimicrobial Properties

Infection control remains a top priority in medical device design. The development of antimicrobial silicone composites—integrating agents such as silver nanoparticles or other biocidal compounds—is gaining momentum. These materials offer long-lasting antimicrobial effects, reducing the need for systemic antibiotics and decreasing healthcare-associated infections.

Smart Silicone Materials for Responsive Medical Devices

The emergence of smart silicones—materials embedded with sensors or responsive elements—ushers in a new era of adaptive medical devices. These silicones can monitor physiological parameters in real-time, such as temperature or pressure, and respond dynamically—for instance, releasing medication or altering stiffness based on the patient's needs. This trend aligns with the broader movement towards personalized medicine.

Innovations in Manufacturing Processes

3D Printing of Silicone Medical Devices

Additive manufacturing techniques are revolutionizing the production of silicone medical products. 3D printing allows for customized, complex geometries that traditional manufacturing cannot achieve efficiently, reducing lead times and costs. Advances in silicone-based printable inks are enabling the fabrication of intricate implants, prosthetics, and surgical tools with high precision.

Injection Molding and Microfabrication

Refined injection molding techniques facilitate mass production of silicone components with consistent quality. Microfabrication methods are also being employed to develop micro-scale silicone devices for minimally invasive procedures, including drug delivery systems and microfluidic platforms.

Emerging Trends in Silicone Medical Device Design

Minimally Invasive and Implantable Devices

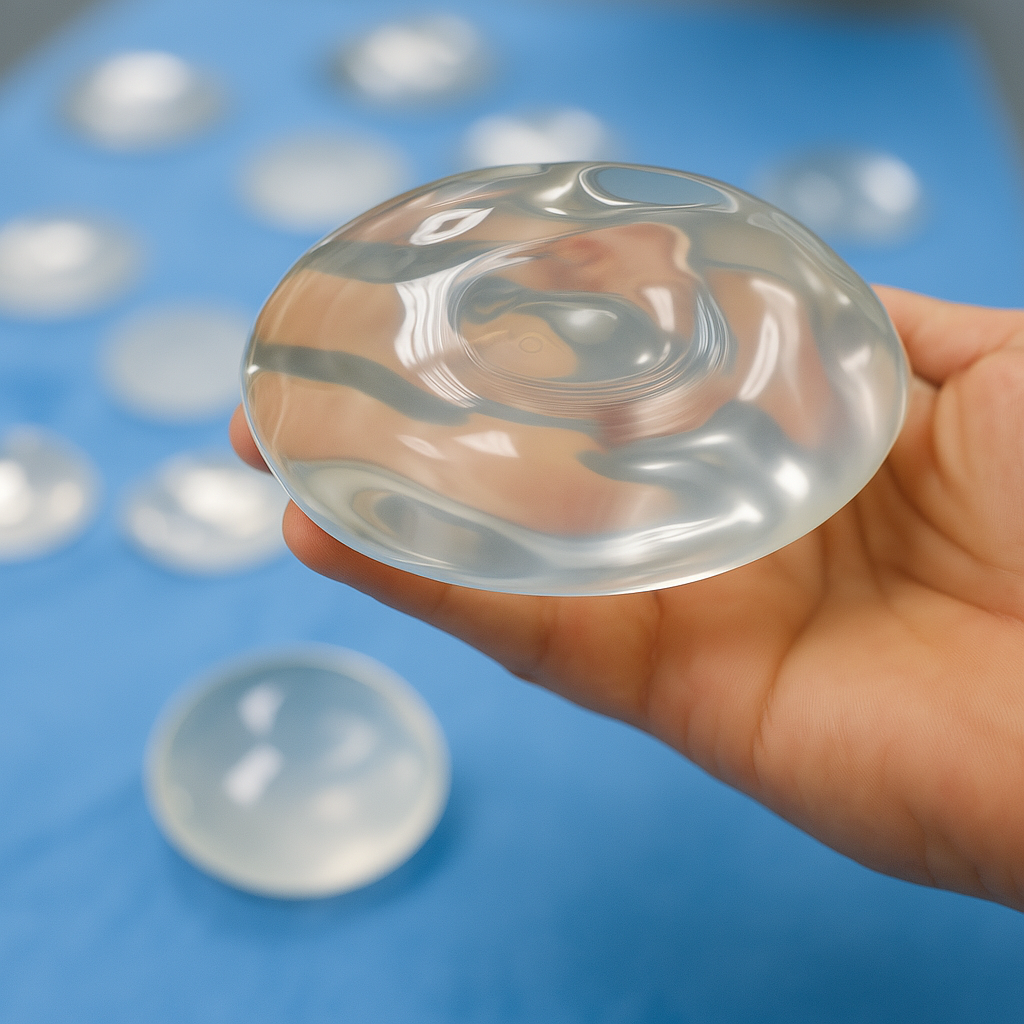

The trend toward less invasive procedures necessitates the development of flexible, durable, and biocompatible silicone implants. These include breast implants, vascular grafts, and joint replacements. Silicone's elasticity and long-term stability make it ideal for such applications, with ongoing research focused on improving implant longevity and reducing complications.

Silicone in Wearable Medical Technologies

The proliferation of wearable health monitoring devices leverages silicone's soft, skin-friendly properties. Future wearable devices will incorporate silicone-based sensors and housings that seamlessly conform to the body, providing accurate data collection while maintaining comfort.

Silicone-Integrated Drug Delivery Systems

Silicone's chemical inertness and permeability control make it suitable for drug-eluting implants and transdermal patches. Innovations aim to fine-tune drug release profiles and enable targeted therapy, especially for chronic conditions such as diabetes or cardiovascular diseases.

Regulatory Landscape and Its Impact on Silicone Medical Products

Stringent Standards and Certification Processes

Regulatory agencies, including the FDA and EMA, are increasingly emphasizing rigorous safety evaluations for silicone medical devices. Future trends involve comprehensive biocompatibility testing, long-term stability assessments, and environmental impact analyses to ensure compliance and safety.

Sustainable and Eco-Friendly Silicone Production

Environmental considerations are influencing regulatory policies. The industry is moving toward sustainable manufacturing practices, including recyclable silicones and green synthesis methods, aligning with global efforts to reduce ecological footprints.

Market Dynamics and Economic Considerations

Growing Demand in Emerging Markets

Increasing healthcare infrastructure investments in regions like Asia-Pacific and Africa are expanding the market for silicone medical products. These markets favor cost-effective, versatile solutions that can be rapidly deployed, fueling innovation and adoption.

Cost Reduction Through Technological Innovation

Automation, additive manufacturing, and material optimization are collectively reducing production costs. These efficiencies enable broader access to advanced silicone medical devices, making high-quality healthcare more affordable worldwide.

Future Outlook: The Road Ahead for Silicone in Healthcare

The trajectory of silicone medical products points toward greater customization, smart functionalities, and enhanced safety profiles. The integration of digital health technologies with advanced silicone materials will facilitate personalized, minimally invasive, and highly effective treatments. As research accelerates, novel composite materials and responsive systems will become commonplace, transforming patient outcomes and healthcare delivery paradigms.

Conclusion: Embracing Innovation for Better Healthcare Outcomes

The future of silicone medical products is bright and dynamic, driven by technological breakthroughs, regulatory evolution, and market demands. The ongoing commitment to material excellence, manufacturing innovation, and patient-centric design will ensure that silicone remains at the forefront of medical device innovation. Stakeholders across the healthcare spectrum must stay vigilant and adaptive to harness these trends effectively, ultimately delivering safer, more effective, and more personalized solutions for patients worldwide.

Relevant Images:

(Insert relevant product images here, such as silicone implants, wearable devices, antimicrobial silicone materials, 3D printed silicone components, and minimally invasive silicone implants.)

Table 1: Key Trends in Silicone Medical Products (2024-2030)

| Trend | Description | Impact |

|---|---|---|

| Advanced Biocompatible Silicone | Development of purer, surface-modified silicones for enhanced tissue compatibility | Reduced adverse reactions, improved patient outcomes |

| Antimicrobial Silicone Composites | Integration of biocidal agents like silver nanoparticles | Lower infection rates, increased device longevity |

| Smart Silicone Materials | Embedding sensors and responsive elements for real-time health monitoring | Personalized, adaptive medical devices |

| 3D Printing of Silicone Devices | Customizable, complex geometries via additive manufacturing | Faster production, tailored solutions |

| Minimally Invasive Silicone Implants | Flexible, durable implants for less invasive procedures | Reduced recovery times, improved patient comfort |

| Silicone in Wearable Tech | Soft, conformable silicone housings and sensors | Enhanced user comfort, accurate data collection |

| Sustainable Silicone Production | Eco-friendly manufacturing processes and recyclable silicones | Reduced environmental impact |