The Future of Silicone Medical Products: Trends to Watch in Healthcare Innovation

- Share

- publisher

- siliconeplus

- Issue Time

- Jul 9,2025

Summary

The future of medical silicone products will revolve around trends such as biocompatibility, smart materials, 3D printing, sustainable manufacturing, and hybrid material integration, driving innovations in personalized medicine, remote monitoring, and environmental sustainability.

The Future of Silicone Medical Products: Trends to Watch in Healthcare Innovation

As the healthcare industry continues to evolve at an unprecedented pace, silicone medical products remain at the forefront of innovation, driven by their unique combination of biocompatibility, durability, and versatility. With ongoing advancements in material science, manufacturing processes, and regulatory standards, the landscape of silicone-based medical devices is poised for significant transformation. This comprehensive analysis explores the most critical trends shaping the future of silicone medical products, providing insights into emerging technologies, sustainable practices, and regulatory challenges that healthcare providers and manufacturers must navigate.

1. The Rising Role of Biocompatible Silicone in Medical Applications

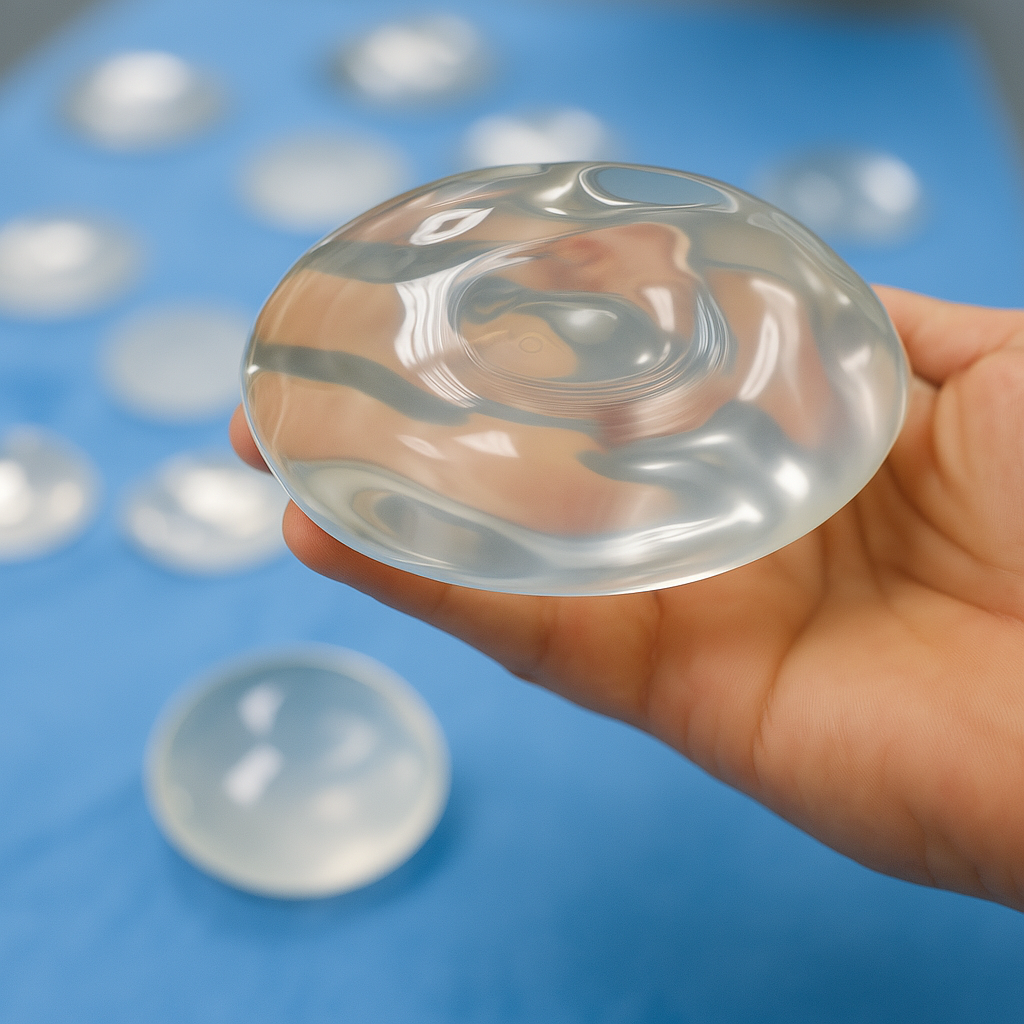

Biocompatibility is the cornerstone of medical-grade silicone, underpinning its widespread use in implants, catheters, prosthetics, and other critical devices. As patient safety and comfort become paramount, innovations in high-purity, medical-grade silicone are enabling safer, more effective treatments.

Enhanced Purity and Safety Standards

Recent developments focus on producing ultra-pure silicones with minimal extractables and leachables, significantly reducing adverse reactions. These advancements ensure long-term stability and biocompatibility, especially vital for implantable devices such as breast implants, joint replacements, and vascular grafts.

Customization for Specific Medical Needs

The future of biocompatible silicone lies in tailored formulations that meet specific clinical requirements. For example, antimicrobial silicone incorporates agents that inhibit bacterial colonization, reducing infection risks. Additionally, silicone with enhanced elasticity improves patient comfort and device integration.

2. Emergence of Smart Silicone Materials in Healthcare

The integration of smart materials into silicone products is revolutionizing medical device functionality, enabling real-time monitoring, adaptive responses, and improved patient outcomes.

Silicone-Embedded Sensors and Electronics

Innovators are embedding miniature sensors within silicone matrices to create wearable health monitors that track vital signs such as heart rate, temperature, and hydration levels. These smart silicone devices facilitate continuous patient monitoring, allowing for early detection of complications and personalized treatment adjustments.

Responsive and Adaptive Silicone Devices

Future silicone products will feature responsive properties—for instance, shape-memory silicones that change form in response to temperature or pH levels. Such innovations enable minimally invasive procedures and dynamic implants that adapt to physiological changes.

3. 3D Printing and Additive Manufacturing Transforming Silicone Medical Device Production

Additive manufacturing has opened new horizons for customized, complex silicone medical devices, overcoming limitations of traditional manufacturing.

Precision and Customization

3D printing allows for rapid prototyping and patient-specific device fabrication, improving fit, functionality, and comfort. This is especially relevant for craniofacial reconstructions, prosthetics, and vascular models.

Cost-Effective and Rapid Production

The ability to produce small batches efficiently reduces costs and accelerates time-to-market for innovative devices. This agility is vital in responding to urgent medical needs and personalized medicine.

4. Sustainability and Eco-Friendly Manufacturing Practices

As environmental concerns grow, the medical sector is adopting sustainable practices in silicone production, focusing on reducing waste, energy consumption, and chemical use.

Green Chemistry in Silicone Synthesis

Developments in green chemistry aim to minimize toxic byproducts during silicone synthesis, incorporating renewable feedstocks and solvent-free processes. These methods produce biocompatible, eco-friendly silicones suitable for sensitive applications.

Recyclability and Circular Economy Models

Efforts are underway to design recyclable silicone materials and establish closed-loop manufacturing systems, reducing environmental impact and promoting sustainability in healthcare.

5. Regulatory and Quality Assurance Challenges

The proliferation of innovative silicone products necessitates robust regulatory frameworks ensuring safety, efficacy, and traceability.

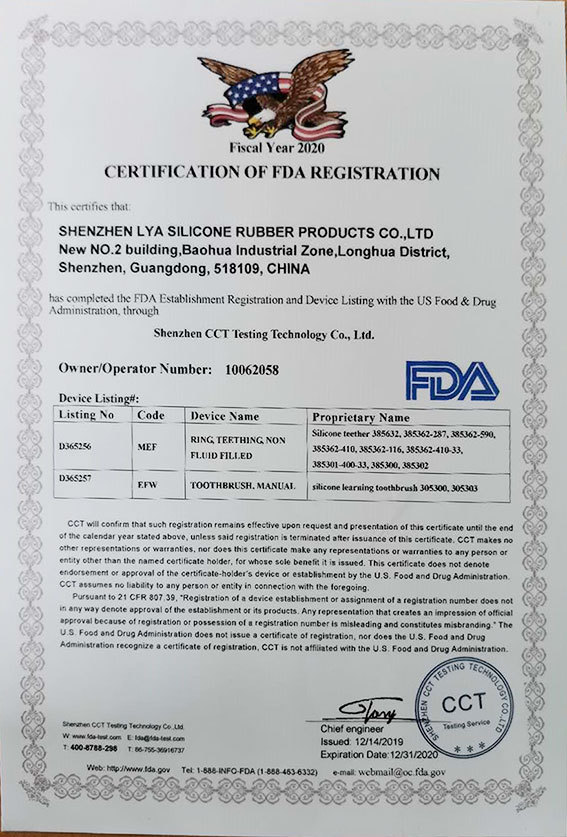

Stringent Testing and Certification

Future trends include comprehensive in vitro and in vivo testing, alongside advanced biocompatibility assessments, to meet evolving standards set by agencies like the FDA and EMA.

Digital Documentation and Traceability

Blockchain and IoT technologies are being integrated for transparent supply chains and product traceability, ensuring quality assurance from raw material sourcing to final delivery.

6. Integration of Silicone with Other Advanced Materials

Combining silicone with nanomaterials, hydrogels, and biopolymers results in hybrid materials with superior properties, expanding the scope of medical applications.

Nanocomposite Silicone

Embedding nanoparticles enhances mechanical strength, antimicrobial properties, and electrical conductivity, enabling new functionalities such as biosensors and drug delivery systems.

Silicone-Hydrogel Hybrids

These materials offer enhanced moisture retention and biological integration, ideal for contact lenses, wound dressings, and implant coatings.

7. The Impact of Digital Health and Telemedicine

The future of silicone medical products is intrinsically linked with the digital health revolution. Remote monitoring devices, connected implants, and telehealth platforms rely heavily on advanced silicone components.

Remote Patient Monitoring Devices

Silicone-based wearables and patches enable continuous health tracking, facilitating remote diagnostics and chronic disease management.

Connected Medical Implants

Smart silicone implants can transmit data, alerting healthcare providers to potential issues such as implant failure or infection, improving patient safety.

8. Challenges and Opportunities in Silicone Medical Product Innovation

While technological advancements offer immense potential, challenges such as regulatory hurdles, cost considerations, and manufacturing scalability remain. Addressing these will unlock new opportunities for market growth and patient-centered care.

Conclusion: Embracing Innovation for a Healthier Future

The future of silicone medical products is marked by remarkable innovation, driven by biocompatibility, smart functionalities, and sustainable practices. As research accelerates and regulatory frameworks adapt, medical-grade silicone will continue to expand its role in personalized medicine, minimally invasive procedures, and digital health solutions. Stakeholders across the healthcare ecosystem must embrace these trends to enhance patient outcomes, reduce environmental impact, and advance medical technology into a new era of healthcare excellence.