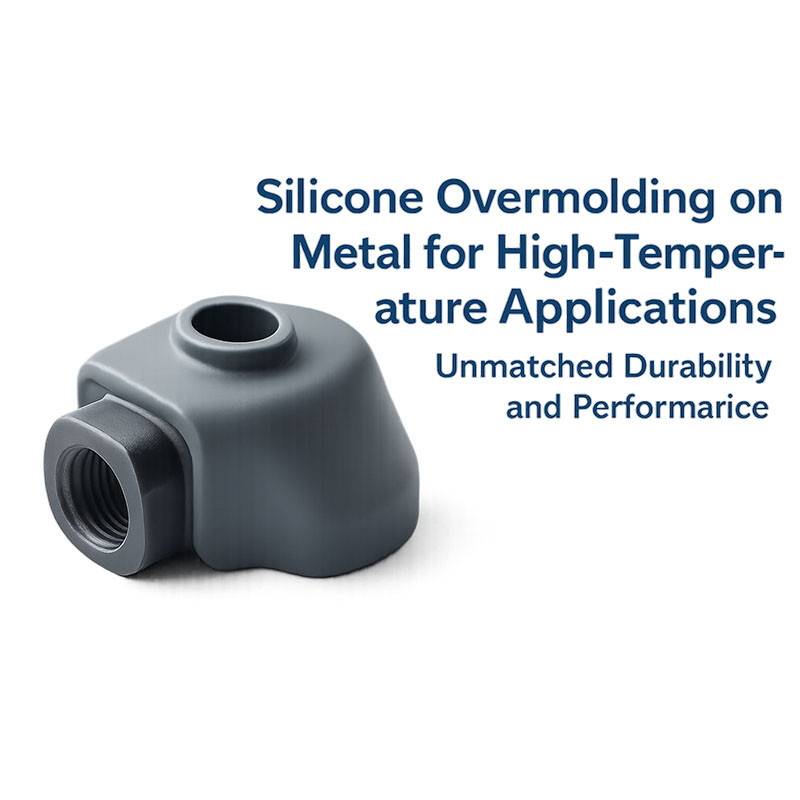

Silicone Overmolding on Metal for High-Temperature Applications: Unmatched Durability and Performance

- Share

- publisher

- siliconeplus

- Issue Time

- Oct 27,2025

Summary

Silicone Overmolding on Metal for High-Temperature Applications — Advanced LSR Technology for Durability, Insulation

Introduction:

In the realm of high-temperature engineering, the demand for materials that combine thermal stability, mechanical robustness, and chemical resistance has never been greater. Silicone overmolding on metal substrates emerges as a pioneering technology, offering superior solutions for industrial, automotive, aerospace, and electronics sectors. This comprehensive exploration details the state-of-the-art techniques, material properties, and applications of organic silicon coatings on metals tailored specifically for extreme temperature environments.

Understanding Silicone Overmolding on Metal: A Technological Breakthrough

Silicone overmolding involves the application of a silicone elastomer directly onto a metal substrate, forming a bonded, protective layer. This process enhances the mechanical properties of the metal component while imparting thermal and chemical resistance. The overmolded silicone layer functions as a thermal insulator, vibration dampener, and corrosion barrier, making it ideal for high-temperature applications where conventional materials fail.

Key advantages include:

1.Exceptional thermal stability up to 300°C and beyond

2.Superior electrical insulation

3.Enhanced mechanical durability

4.Corrosion and chemical resistance

5.Flexibility and elasticity, accommodating thermal expansion

Material Properties of Silicone for High-Temperature Overmolding

Silicone elastomers used in overmolding are engineered for extreme conditions. Their chemical composition endows them with remarkable properties:

Thermal Stability:

Can withstand temperatures ranging from -60°C to 300°C, with specialized formulations exceeding this range.Electrical Insulation:

Dielectric strength surpassing 20 kV/mm, essential for electrical and electronic applications.Chemical Resistance:

Resistance to oils, fuels, solvents, and ozone.Flexibility:

Maintains elasticity over thermal cycles, preventing cracking or delamination.UV and Weather Resistance:

Suitable for outdoor applications.The interfacial adhesion between silicone and metal is critical. Surface treatments, such as plasma activation or silane coupling agents, significantly enhance bonding strength, ensuring long-term reliability.

High-Temperature Metal Substrates Compatible with Silicone Overmolding

Selecting the appropriate metal substrate is pivotal. Common metals include:

Metal Type | Properties | Application Suitability |

| Aluminum | Lightweight, good thermal conductivity, corrosion-resistant | Electronics, aerospace, automotive parts |

| Stainless Steel | High strength, corrosion resistance, high melting point | Heavy-duty industrial components, marine applications |

| Copper | Excellent thermal and electrical conductivity | Electrical connectors, heat sinks |

| Titanium | Outstanding strength-to-weight ratio, corrosion resistant | Aerospace, medical devices |

Innovative Overmolding Techniques for High-Temperature Applications

1. Surface Preparation and Treatment

Achieving strong adhesion requires meticulous surface conditioning:

Mechanical roughening (sandblasting or abrasion)

Chemical cleaning to remove oils and contaminants

Plasma treatment to activate surfaces

Application of silane coupling agents to improve covalent bonding

2. Precision Mold Design and Material Compatibility

Molds are engineered to accommodate thermal expansion and material flow characteristics. The silicone compound must be formulated to ensure uniform coverage and full encapsulation of the metal part.

3. Curing Processes

High-temperature curing cycles—often between 150°C to 200°C—are optimized to maximize cross-linking within the silicone matrix, ensuring dimensional stability and long-term performance.

Applications of Silicone Overmolding on Metal in High-Temperature Environments

1.Aerospace and Space Industry

Components such as rocket engine parts, sensor housings, and thermal protection systems benefit from silicone-coated metal parts that withstand extreme thermal cycling and vibrational stresses.

Engine components, sensor housings, and electrical connectors require robust insulation and thermal management. Silicone overmolding provides vibration damping, thermal insulation, and chemical protection.

3.Industrial Electronics

Devices operating in harsh environments—including power modules, control units, and circuit boards—rely on silicone coatings for thermal management and electrical insulation, ensuring reliable operation over extended periods.

Titanium implants and surgical instruments exposed to sterilization at high temperatures utilize silicone overmolding to prevent corrosion and ensure biocompatibility.

Advantages of Silicone Overmolding on Metals for High-Temperature Applications

Enhanced Thermal Management:

Silicone acts as an effective insulator, reducing heat transfer to sensitive components.Vibration and Shock Absorption:

The elastomeric nature dampens vibrations, protecting delicate parts.Extended Service Life:

Resistance to oxidation, corrosion, and thermal fatigue prolongs component lifespan.Electrical Safety:

High dielectric strength ensures safe operation in electrical assemblies.Design Flexibility:

Ability to conform to complex geometries and provide customized protective layers.Challenges and Solutions in Silicone Overmolding for High-Temperature Use

1.Adhesion at the Metal-Silicone Interface

Challenge: Achieving strong, durable bonds at high temperatures.

Solution: Surface treatments like plasma activation and silane coupling agents significantly improve adhesion. Selection of compatible silicone formulations tailored for metal substrates also enhances bonding.

2.Thermal Expansion Mismatch

Challenge: Differential expansion can cause delamination or cracking.

Solution: Use of highly elastic silicone formulations and controlled curing processes to accommodate thermal stresses.

3.Material Compatibility

Challenge: Ensuring silicone formulations do not degrade or outgas under high temperatures.

Solution: Employing high-temperature silicone elastomers with optimized curing cycles and low outgassing properties.

Future Trends in Silicone Overmolding for High-Temperature Metal Components

Advanced Silicone Formulations

Development of high-temperature silicones with improved thermal stability up to 350°C, expanding application horizons.

Smart Coatings and Embedded Sensors

Integration of sensor technology within silicone layers for real-time monitoring of temperature, stress, or corrosion.

Nanocomposite Silicone Materials

Incorporating nanoparticles such as ceramic fillers or carbon nanotubes to enhance thermal conductivity, mechanical strength, and fire resistance.

Conclusion: The Future of High-Temperature Silicone Overmolding on Metals

Silicone overmolding on metal substrates stands at the forefront of material engineering, offering unmatched performance in high-temperature environments. Its versatility, durability, and adaptability make it an indispensable solution across multiple industries requiring reliable thermal and electrical insulation, mechanical protection, and chemical resistance.

As material science advances, the development of next-generation silicone composites and innovative surface treatment techniques will further expand the capabilities of this technology, cementing its role in high-temperature engineering applications worldwide.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883