Premium Liquid Silicone Parts Products – Customized for Performance

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- Apr 16,2025

Summary

Liquid silicone rubber (LSR) has rapidly become the preferred material across industries requiring high-precision, biocompatibility, and extreme durability.

Why Liquid Silicone Is the Future of High-Performance Components

Liquid silicone rubber (LSR) has rapidly become the preferred material across industries requiring high-precision, biocompatibility, and extreme durability. At Siliconeplus, we specialize in custom liquid silicone parts products tailored to meet the most demanding industrial standards.

Whether you're in automotive, medical, consumer electronics, or wearable devices, our LSR solutions are designed for precision molding, long-term reliability, and material consistency.

What Are Liquid Silicone Parts Products?

Liquid silicone parts products refer to components manufactured through injection molding using two-component LSR material. These products are known for:

High temperature resistance (up to 200°C+)

Excellent flexibility and rebound

Chemical stability

Biocompatibility (suitable for skin contact or medical-grade applications)

Transparency or custom coloring

At Siliconeplus, we manufacture LSR parts for industries that demand zero-defect, tight-tolerance, and complex geometries.

Industries We Serve with Liquid Silicone Parts Products

1. Medical & Healthcare

We produce medical-grade liquid silicone parts including:

Respirator masks

Breast pump valves

Skin-contact seals and tubing

All products meet FDA and ISO 10993 compliance, ensuring safe use in healthcare settings.

2. Automotive Applications

Our LSR automotive components are engineered for:

High-temperature engine seals

EV battery insulation

Durable gaskets and vibration dampers

The combination of heat resistance and mechanical stability makes LSR ideal for next-gen vehicles.

3. Consumer Electronics & Wearables

We supply liquid silicone parts for 3C and smart devices:

Button pads

Waterproof seals

Device covers

Our LSR process ensures soft-touch feel, UV stability, and overmolding compatibility with PC/ABS/metal.

Why Choose Siliconeplus for Liquid Silicone Parts Products?

We are not just a manufacturer — we are your engineering partner. Our strengths:

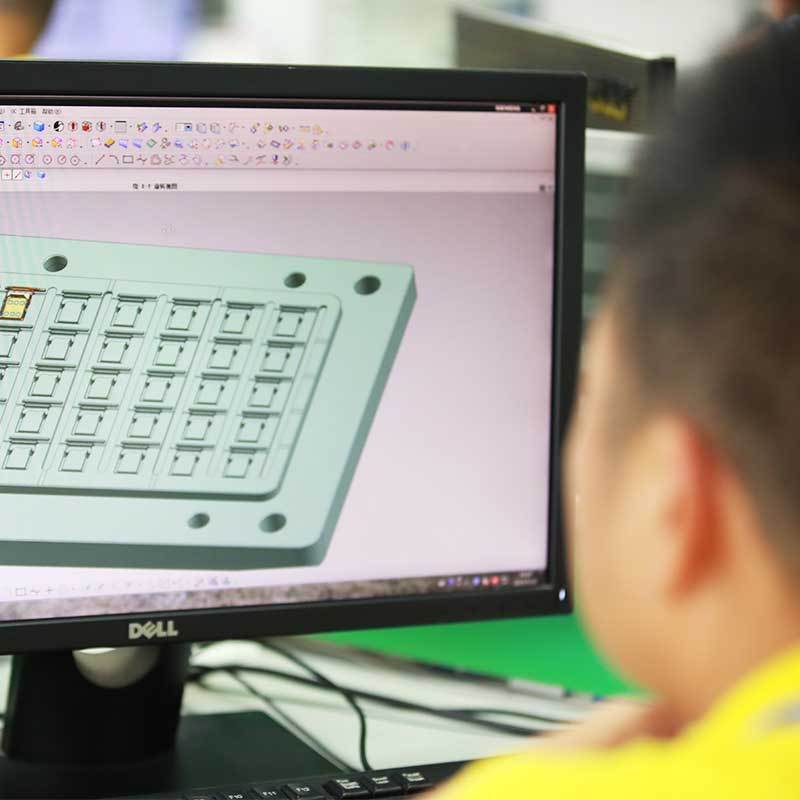

In-house mold design & fabrication

20+ years of LSR processing experience

Cleanroom production environments

Rapid prototyping & mass production capabilities

Strict quality control and global compliance certifications

We offer end-to-end solutions from material selection to final packaging, helping you reduce development cycles and control costs.

Liquid Silicone Parts: Customized to Your Specifications

We support full customization for:

Hardness (10A–70A Shore)

Color matching

Overmolding (plastic, FPC, metal inserts)

Functional coatings or surface treatments

Sterilization compatibility (ETO, autoclave, gamma)

Our team works closely with your engineers to develop products that not only meet mechanical and environmental requirements but also elevate brand value and product experience.

Start Your Project with Siliconeplus

If you're looking for a reliable, expert partner in liquid silicone parts products, we’re here to help. Our technical team is ready to assist with DFM analysis, rapid samples, and volume production.

Contact us now for a free consultation or to request a quote tailored to your project needs.