Medical LSR Products for Respiratory Devices: What’s New?

- Share

- publisher

- siliconeplus

- Issue Time

- Sep 1,2025

Summary

Medical-grade LSR is transforming respiratory devices with safer formulations, innovative designs for comfort and durability.

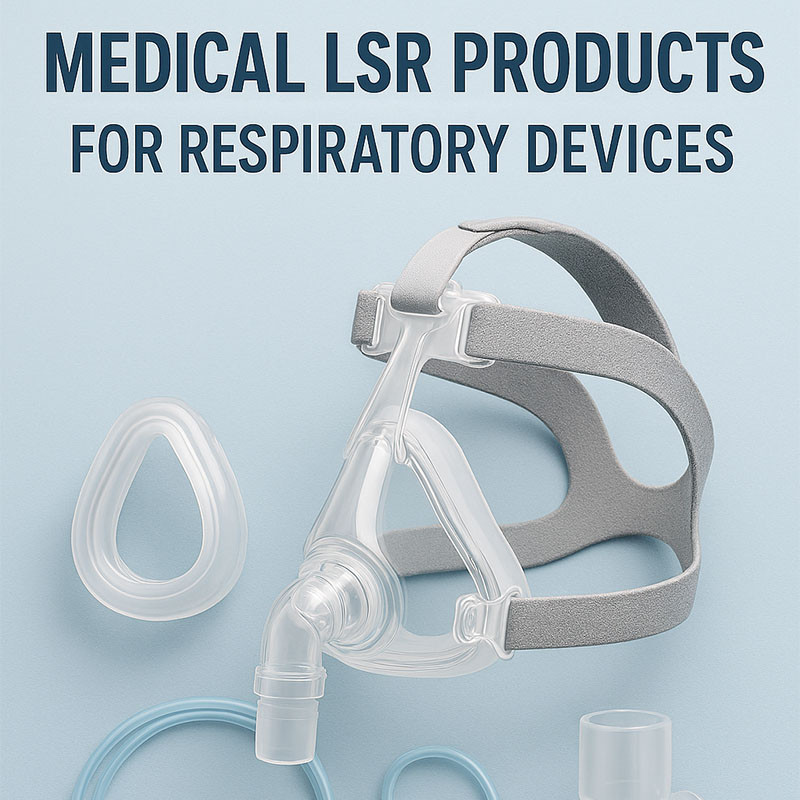

Medical LSR Products for Respiratory Devices: What’s New?

Introduction: The Evolution of LSR in Respiratory Medical Devices

In the rapidly advancing field of respiratory care, Liquid Silicone Rubber (LSR) has emerged as a critical material, revolutionizing the design, manufacturing, and performance of medical devices. The unique combination of biocompatibility, durability, flexibility, and chemical resistance makes LSR an ideal choice for respiratory applications, from ventilator components to nasal masks and tubing. As healthcare demands escalate, especially amid global health crises, the development of cutting-edge LSR products tailored for respiratory devices has become a focal point for innovation.

This comprehensive overview explores the latest advancements in medical-grade LSR products for respiratory devices, emphasizing new formulations, manufacturing techniques, and design innovations that enhance patient safety, device longevity, and clinical efficacy.

The Critical Role of LSR in Modern Respiratory Devices

Liquid Silicone Rubber has become synonymous with medical-grade elastomers due to its exceptional performance in sensitive environments. Its non-reactive nature ensures minimal risk of allergic reactions or toxicity, making it suitable for long-term contact with human tissue and fluids.

Key Benefits of Medical LSR in Respiratory Devices

- Biocompatibility: Meets stringent ISO 10993 standards, ensuring safety for prolonged skin contact.

- Transparency: Facilitates visual inspection of fluid and air pathways.

- Temperature Resistance: Maintains performance across a broad temperature spectrum, vital for sterilization processes.

- Chemical and Environmental Resistance: Withstands disinfectants, cleaning agents, and bodily fluids.

- Flexibility and Softness: Provides comfort and secure sealing in masks and tubing.

- Durability and Tear Resistance: Ensures longevity and reduces replacement frequency.

Recent Innovations in Medical LSR Formulations for Respiratory Applications

1. Advanced Medical-Grade LSR Formulations for Enhanced Biocompatibility

Recent developments have led to formulations that significantly reduce extractables and leachables, ensuring higher purity and greater patient safety. These formulations incorporate novel catalysts and crosslinking agents that minimize residual chemicals post-curing.

2. UV and Electron Beam (E-beam) Crosslinkable LSR

Innovative crosslinking technologies allow for rapid curing using UV light or E-beam radiation, enabling precise control over material properties. This advancement reduces production times and enhances the dimensional stability of respiratory components.

3. Anti-Microbial and Anti-Fog LSR Materials

The integration of anti-microbial agents directly into LSR formulations offers preventative measures against bacterial colonization on respiratory devices. Additionally, anti-fog coatings or intrinsically anti-fog LSR improve visual clarity, vital for devices like face masks and ventilators.

Manufacturing Breakthroughs: Precision and Scalability

1. Injection Molding with High-Precision Micro-Features

Modern injection molding techniques now enable the production of complex geometries with microscale features, essential for sealing surfaces and airflow channels in respiratory devices. The use of high-temperature, low-viscosity LSR allows for fine detail reproduction and consistent quality.

2. Overmolding and Multi-Material Integration

Overmolding technologies facilitate the bonding of LSR to other materials like medical plastics or metal components, creating multi-layered and multi-functional parts. This approach enhances sealing, flexibility, and mechanical strength of respiratory devices.

Design Innovations: Improving Patient Comfort and Device Performance

1. Ergonomic Mask Components with Soft LSR

New design paradigms focus on maximizing comfort through soft, conformable LSR cushions and seals that adapt precisely to facial contours, reducing pressure points and skin irritation.

2. Low-Force, Easy-Release Valves and Connectors

Innovations in LSR valve components incorporate flexible, low-resistance materials that ease assembly and disassembly, promoting hygiene and maintenance.

3. Antiviral and Antiviral-Resistant LSR Surfaces

Research into surface treatments and additives has led to antiviral LSR coatings that actively neutralize virus particles, adding an extra layer of safety for respiratory care.

Case Studies: Leading LSR Products Transforming Respiratory Care

| Product | Description | Key Features | Innovations |

|---|---|---|---|

| Silicone Mask Seal | Soft, conformable seal for non-invasive ventilation | High elasticity, biocompatibility, anti-allergenic | Antimicrobial additive, anti-fog coating |

| Ventilator Tubing | Flexible, durable tubing for respiratory circuits | Chemical resistance, low extractables | UV-crosslinkable formulation for sterilization compatibility |

| Nasal Interface Components | Soft, skin-friendly nasal cushions | Tear-resistant, low compression set | Customizable via 3D printing |

| Anti-Fog Valve Components | Valves with integrated anti-fog LSR | Clear, reliable airflow control | Embedded antimicrobial agents |

| Sterilizable Respiratory Connectors | Connectors resistant to repeated sterilization | High-temperature stability | Multi-material overmolding for enhanced sealing |

Future Directions: The Next Generation of Medical LSR for Respiratory Devices

Smart LSR Materials with Embedded Sensors

Emerging smart silicone materials capable of integrating sensors for real-time monitoring of pressure, temperature, or gas composition within respiratory circuits.

Bioactive LSR for Enhanced Healing

Development of bioactive silicone formulations that promote tissue regeneration or reduce inflammation, opening avenues for implantable respiratory devices.

Sustainable and Eco-Friendly LSR Solutions

Focus on bio-based and recyclable LSR formulations that align with green manufacturing practices, reducing environmental impact without compromising performance.

Conclusion: Leading the Charge in Medical LSR Innovation for Respiratory Devices

The landscape of medical LSR products for respiratory devices is undergoing a paradigm shift, driven by material science breakthroughs, advanced manufacturing techniques, and innovative design principles. These developments are not only enhancing device performance and patient comfort but also elevating safety standards across the healthcare industry.

As demand for reliable, safe, and efficient respiratory solutions continues to grow, the role of cutting-edge LSR technology becomes ever more critical. We remain committed to pioneering new formulations and manufacturing processes that push the boundaries of what is possible in medical silicone elastomers, ensuring better patient outcomes and robust healthcare solutions worldwide.