Innovations in Silicone Rubber Part Design for Better Functionality and Durability

- Share

- publisher

- siliconeplus

- Issue Time

- Aug 6,2025

Summary

This article explores breakthroughs in silicone rubber material, and manufacturing, highlighting enhanced functionality, durability, and smart integration across various high-performance industries.

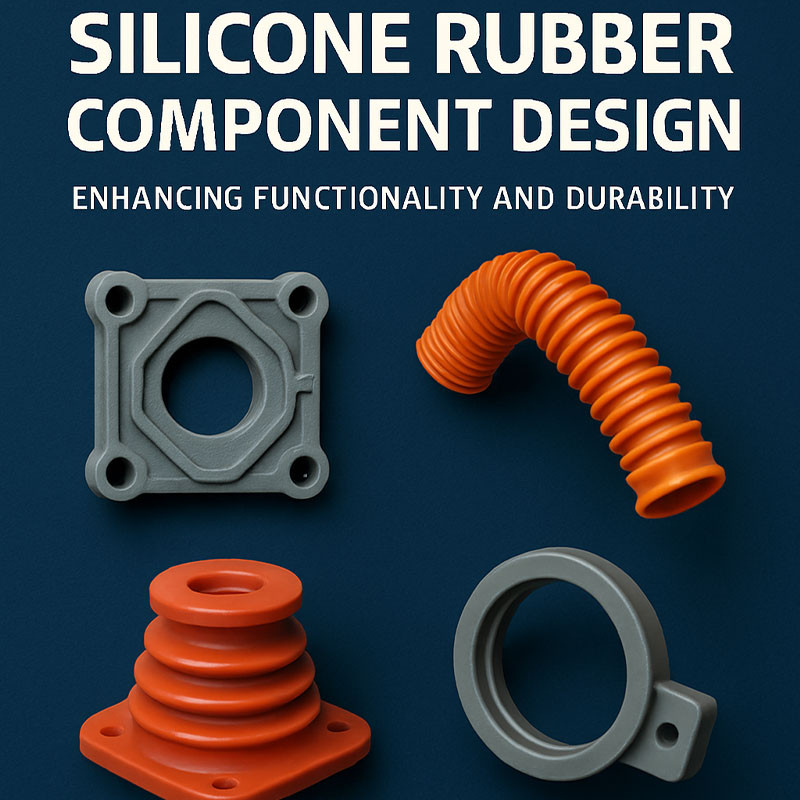

Innovations in Silicone Rubber Part Design for Better Functionality and Durability

In the rapidly evolving landscape of industrial manufacturing, silicone rubber components are increasingly vital due to their exceptional performance characteristics, including flexibility, temperature resistance, chemical stability, and biocompatibility. As industries demand more reliable, durable, and multifunctional silicone parts, groundbreaking innovations in design and manufacturing processes are setting new standards. This comprehensive exploration delves into the latest advancements in silicone rubber part design, emphasizing how these innovations significantly enhance functionality and durability for a broad spectrum of applications.

The Evolution of Silicone Rubber Material Technology

Silicone rubber has long been favored for its versatility and resistance to extreme environmental conditions. Recent advancements focus on material formulations that push the boundaries of traditional silicone properties.

Innovative Design Techniques for Silicone Rubber Parts

Design innovation is pivotal in achieving optimized performance. Incorporating advanced design methodologies ensures functional efficiency, ease of manufacturing, and long-term durability.

3D Modeling and Simulation

The integration of 3D CAD modeling and finite element analysis (FEA) allows for precise stress analysis and deformation prediction under various operational conditions. This process enables engineers to fine-tune geometries, minimize material usage, and maximize lifespan.

Advanced Manufacturing Processes Elevating Silicone Part Quality

The evolution of manufacturing technologies plays a critical role in producing high-precision silicone components with superior mechanical properties.

Liquid Silicone Rubber (LSR) Injection Molding

LSR injection molding offers high repeatability, fine detail replication, and rapid cycle times. The process is ideal for mass production of complex silicone parts, such as medical devices, electronic seals, and automotive gaskets.

Additive Manufacturing (3D Printing)

Emerging 3D printing techniques using silicone-based resins enable the creation of complex geometries that are difficult to achieve with traditional molding. This approach accelerates prototyping, customization, and small-batch production.

Silicone Overmolding and Multi-Material Integration

Overmolding techniques combine silicone with other materials, such as thermoplastics or metals, to produce multi-functional parts. This process enhances mechanical strength, electrical insulation, and chemical resistance.

Design Innovations for Enhanced Functionality

Silicone rubber parts are frequently used in sealing, insulation, vibration damping, and biomedical applications. The following innovations address specific functional challenges.

Embedded Microchannels for Self-Healing and Fluid Flow

The integration of microchannels within silicone components enables self-healing properties or fluid transport functionalities. These features are crucial in medical devices and fluid management systems, improving reliability and performance.

Smart Silicone Components with Embedded Sensors

Embedding sensors within silicone parts allows for real-time monitoring of pressure, temperature, and strain. These smart components facilitate predictive maintenance and performance optimization in automotive and industrial settings.

Enhanced Surface Texturing for Improved Grip and Seal Integrity

Innovative surface texturing techniques, such as micro-patterning and diamond-texture, significantly improve frictional properties and seal effectiveness. This is especially beneficial in medical seals, consumer electronics, and wearable devices.

Durability-Boosting Design Strategies

Long-term performance stability is critical for silicone parts in harsh environments. The following strategies are transforming durability standards.

Oxidation and UV Resistance Coatings

Applying specialized coatings enhances resistance to oxidation and UV degradation, extending the service life of silicone components exposed to sunlight and oxidative environments.

Reinforced Silicone with Fiber Composites

Integrating fiber reinforcements such as aramid, glass, or carbon fibers into silicone matrices dramatically improves tensile strength and abrasion resistance, ensuring long-lasting performance in mechanically demanding applications.

Design for Fatigue Resistance

Incorporating geometric features that distribute stress uniformly reduces fatigue failure. Techniques such as fillet radii, stress-relief notches, and layered reinforcement are instrumental in this regard.

Case Studies: Breakthroughs in Silicone Rubber Part Design

Medical Silicone Devices with Microchannel Networks

A leading medical device manufacturer redesigned catheter seals by integrating microchannel networks for fluid management. This innovation resulted in reduced infection risk, improved flexibility, and enhanced user safety.

Automotive Seals with Embedded Sensors

An automotive OEM developed smart door seals with embedded pressure sensors. These sensors detect seal integrity and leakage, enabling preventive maintenance and cost savings.

Aerospace Silicone Components with Optimized Topology

An aerospace company employed topology optimization to design lightweight silicone gaskets that withstand extreme temperature fluctuations while maintaining sealing performance.

Future Directions in Silicone Rubber Part Design

The convergence of material science, digital manufacturing, and smart technology heralds a new era for silicone rubber components. Anticipated trends include:

- Nanotechnology enhancements for self-healing and adaptive properties

- AI-driven design algorithms for optimized geometries

- Biodegradable silicone formulations for sustainable applications

- Integration of IoT sensors for real-time health monitoring

Conclusion

Innovations in silicone rubber part design are revolutionizing how industries approach performance, durability, and functionality. Through material advancements, state-of-the-art design techniques, and cutting-edge manufacturing processes, silicone components are becoming more robust, adaptable, and integrative. These developments not only meet but exceed the rigorous demands of modern applications, ensuring long-term reliability and operational excellence. As technology advances, the future of silicone rubber part design promises even more innovative solutions that will continue to elevate industry standards.