Injection Molding: A Comprehensive Guide to Custom Silicone Products

- Share

- publisher

- siliconeplus editor

- Issue Time

- Sep 27,2024

Summary

Injection molding enables precise, scalable production of custom silicone products. We specialize in high-quality, durable solutions for medical, industrial, and consumer needs.

Injection Molding: A Comprehensive Guide to Custom Silicone Products

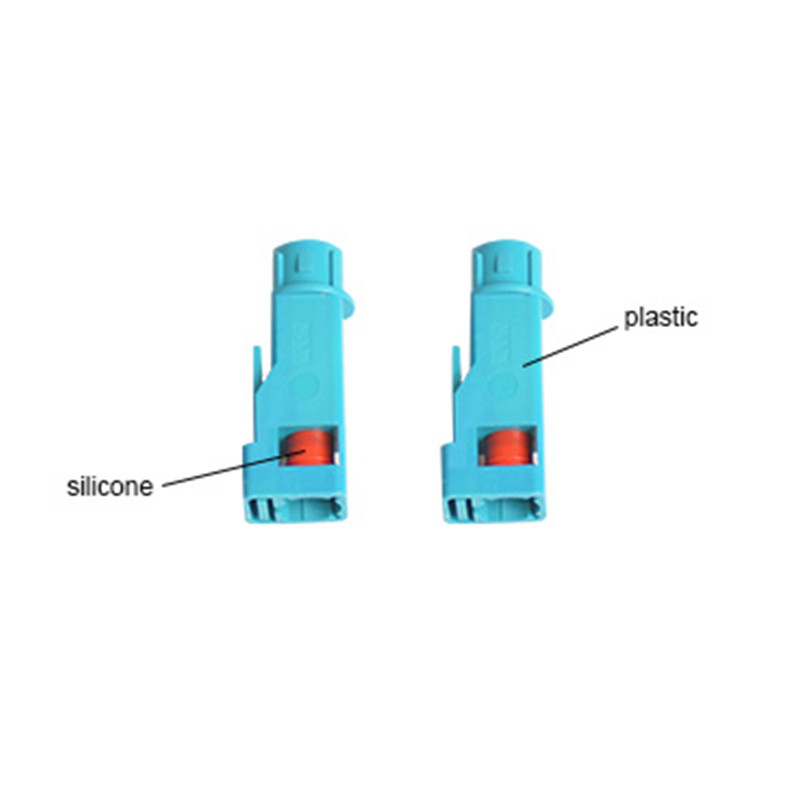

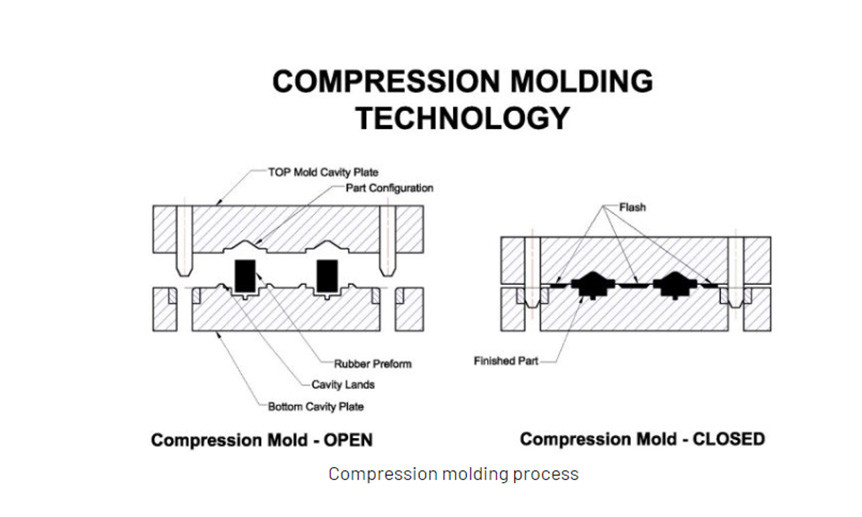

Injection molding is a highly efficient and versatile manufacturing process widely used in producing custom silicone products. It involves injecting molten silicone material into a precisely designed mold cavity, where it cools and solidifies to form the desired shape. This process is ideal for creating complex, high-precision components used in various industries, including medical devices, automotive parts, and electronics.

As a leading source factory specializing in silicone overmolding, we excel in customizing silicone products to meet our clients' specific needs. Our expertise in injection molding ensures high-quality, durable, and flexible solutions, whether it’s for high-performance seals, waterproof connectors, or medical-grade parts.

Benefits of Injection Molding for Custom Silicone Products:

Precision and consistency: The process guarantees uniformity and accuracy, essential for intricate designs and high-demand applications.

Scalability: Injection molding allows for mass production of custom silicone products, maintaining quality across large volumes.

Material versatility: We utilize a range of silicone types, including medical-grade silicone, to create products that meet stringent industry standards.

By leveraging our in-house capabilities and advanced injection molding technology, we can tailor silicone products that meet unique specifications while maintaining cost efficiency and rapid turnaround times. Whether you need specialized components for industrial, medical, or consumer applications, our team is ready to deliver customized solutions that exceed expectations.

In summary, injection molding is the key to creating custom silicone products with precision, quality, and scalability, making it an essential process in modern manufacturing.