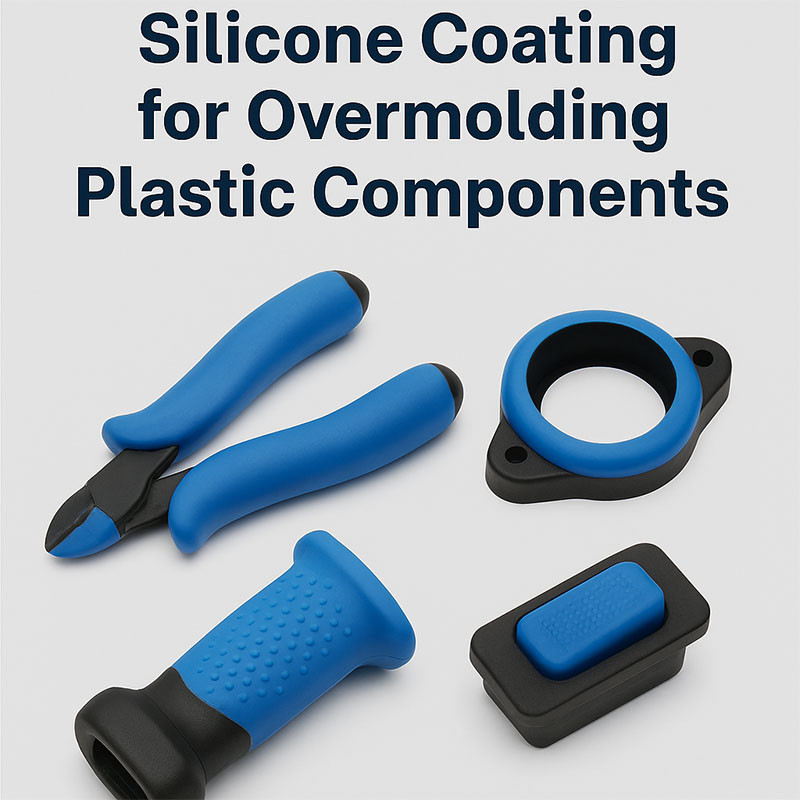

How to Select the Right Silicone Coating for Overmolding Plastic Components

- Share

- publisher

- siliconeplus

- Issue Time

- Dec 15,2025

Summary

A practical guide to selecting silicone coatings for plastic overmolding to ensure adhesion,and long-term performance.

Introduction: The Critical Role of Silicone Coatings in Overmolding Applications

In today's highly competitive manufacturing landscape, overmolding plastic components has become a cornerstone process for creating robust, flexible, and aesthetically appealing products. Central to this process is the application of silicone coatings, which serve to enhance durability, environmental resistance, tactile feel, and functional performance. Selecting the appropriate silicone coating is a complex task that requires a thorough understanding of material properties, application environments, and end-use requirements.

This comprehensive guide explores the key factors and expert considerations necessary to accurately select and implement the ideal silicone coating for your overmolding projects, ensuring long-term success and product excellence.

Understanding Silicone Coatings: Composition and Core Properties

What Are Silicone Coatings?

Silicone coatings are high-performance materials composed primarily of silicone polymers, often blended with fillers, pigments, and adhesion promoters. Their unique chemical structure imparts exceptional thermal stability, flexibility, and weather resistance, making them ideal for protective and aesthetic applications on plastic substrates.

Key Properties of Silicone Coatings

| Property | Description | Significance in Overmolding |

Temperature Resistance | Can withstand temperatures from -60°C to +300°C | Ensures coating integrity during high-heat processes or environments |

Flexibility & Elasticity | Maintains flexibility over wide temperature ranges | Prevents cracking or delamination during mechanical stress |

| UV & Weather Resistance | Resists degradation from UV exposure, moisture, and environmental pollutants | Extends product lifespan in outdoor applications |

| Chemical Resistance | Resistant to oils, solvents, and chemicals | Maintains performance in harsh chemical environments |

| Electrical Insulation | Excellent dielectric properties | Suitable for electronic components |

Critical Factors in Selecting Silicone Coatings for Overmolding

1. Compatibility with Base Plastic Material

Understanding substrate compatibility is paramount. Silicone coatings must adhere strongly to the underlying plastic without causing degradation or warping. Compatibility varies based on plastic type:

Thermoplastics like ABS, Polycarbonate, and Polypropylene: Require specialized adhesion promoters for optimal bonding.

Thermosets and Elastomers: May need different formulations for compatibility.

Expert Tip: Conduct adhesion tests on small samples before full-scale application.

2. Application Environment and End-Use Conditions

The operational environment dramatically influences the choice of silicone coating:

Outdoor applications: Prioritize UV stability and weather resistance.

High-temperature environments: Select silicones with superior thermal stability.

Chemical exposure: Opt for chemically resistant formulations.

Electrical components: Ensure dielectric strength and insulation properties.

3. Mechanical Performance Requirements

Durability and flexibility are often competing demands. The coating must:

Resist mechanical wear, scratches, and impacts.

Maintain flexibility during bending or deformation.

Prevent cracking or peeling over the product’s lifespan.

4. Coating Thickness and Uniformity

Achieving an even, controlled layer thickness is crucial. Excessively thick coatings can impair dimensional accuracy, while too thin layers may compromise protection. Use precision spraying or brushing techniques and automated coating systems for consistency.

Types of Silicone Coatings Suitable for Overmolding

1. Two-Component Silicone Coatings

Advantages: Superior adhesion, enhanced chemical resistance, and customizable properties.

Use cases: High-performance applications demanding custom formulations.

2. One-Component Silicone Coatings

Advantages: Ease of application, fast curing, and convenience.

Use cases: General-purpose coatings for mass production.

3. High-Temperature Silicone Coatings

Advantages: Withstands extreme heat without degradation.

Use cases: Electrical housings, automotive parts, and industrial equipment.

4. UV-Resistant Silicone Coatings

Advantages: Long-term outdoor durability.

Use cases: Exterior panels and lighting fixtures.

Application Techniques for Silicone Coatings

1. Spraying

Provides uniform coverage over complex geometries. Ideal for large volume production.

2. Brushing and Rolling

Suitable for small batches or touch-up work.

3. Dip Coating

Ensures complete coverage of intricate parts, especially in small or detailed components.

4. Automated Coating Systems

Offer precision, consistency, and high throughput, essential for mass manufacturing.

Ensuring Proper Adhesion and Compatibility

Adhesion Promoters and Primers

Use silane-based adhesion promoters to enhance bonding between silicone coatings and plastic substrates, especially when

working with difficult plastics like polypropylene.

Surface Preparation

Cleaning: Remove oils, dust, and residues.

Surface Roughening: Slight abrasion can improve mechanical adhesion.

Pre-treatment: Use plasma or corona discharge to activate surfaces.

Testing and Quality Assurance

Adhesion Testing

Perform cross-hatch or peel tests to verify coating adherence under operational stresses.

Environmental Testing

Simulate UV exposure, temperature cycling, and chemical immersion to validate long-term performance.

Electrical Testing

For electronic components, measure dielectric strength and insulation resistance.

Case Studies: Successful Silicone Coating Applications in Overmolding

Applying UV-resistant, high-temperature silicone coatings on sensor housings to ensure durability and reliable operation under extreme conditions.

Using flexible, insulating silicone coatings for wearable device casings, combining aesthetic appeal with protection against moisture and impact.

Implementing biocompatible silicone coatings on plastic components to prevent microbial growth and facilitate sterilization.

Conclusion: Mastering the Art of Silicone Coating Selection

Choosing the right silicone coating for overmolding plastic components is a multifaceted process that demands technical expertise, precise testing, and strategic planning. By thoroughly understanding the material properties, application environment, and performance requirements, manufacturers can optimize product durability, functionality, and aesthetics.

Investing in the right silicone coating not only extends the service life of plastic components but also enhances customer satisfaction and brand reputation. Through careful selection, meticulous application, and rigorous testing, organizations can achieve superior results in their overmolding endeavors

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883