How to Select the Right Liquid Silicone Rubber (LSR) for Your Application

- Share

- publisher

- siliconeplus

- Issue Time

- Sep 4,2025

Summary

Guide to selecting optimal Liquid Silicone Rubber (LSR) for performance, biocompatibility, and application-specific needs.

Selecting the optimal Liquid Silicone Rubber (LSR) is a critical step in ensuring the success of your manufacturing process and the performance of your final product. As a leading provider of high-quality LSR solutions, we understand the importance of matching the material's properties precisely to your application's unique requirements. This comprehensive guide offers in-depth insights into choosing the right LSR, covering everything from material properties and types to processing techniques and application-specific considerations.

Hardness is typically measured in Shore A or Shore 00, depending on flexibility requirements:

Hardness is typically measured in Shore A or Shore 00, depending on flexibility requirements:

| Hardness Level | Application Examples |

10-20 Shore 00 | Soft, flexible seals, gaskets |

| 30-50 Shore A | Medical tubing, flexible components |

| 60-80 Shore A | Structural parts, rigid seals |

1.Chemical and Environmental Resistance

Your application’s exposure to chemicals, UV radiation, moisture, or ozone influences LSR selection. For instance:

Medical devices demand biocompatibility and chemical inertness.

Outdoor electronics require UV and ozone resistance.

Food-grade applications necessitate compliance with FDA or EU standards.

2.Biocompatibility and Regulatory Compliance

For medical, food contact, or cosmetic applications, selecting biocompatible LSRs that meet strict regulatory standards (ISO 10993, FDA, EU regulations) is paramount.

3.Transparency and Aesthetic Requirements

If visual appearance is critical—such as in consumer electronics or medical devices—opt for transparent or colored LSRs with high clarity and color stability.

Types of Liquid Silicone Rubber (LSR): Tailored for Diverse Applications

Understanding the different types of LSR available allows for precise matching to your application's needs. The main categories include:

1. Standard LSR

Ideal for general-purpose applications, offering balanced mechanical, thermal, and chemical properties. Suitable for gaskets, seals, and medical devices.

2. High-Temperature LSR

Designed to withstand extreme heat, these formulations are perfect for automotive, electrical insulation, and industrial applications where thermal stability is critical.

3. Food-Grade and Medical LSR

Manufactured with biocompatibility in mind, these formulations comply with FDA and ISO 10993 standards, suitable for medical implants, food contact items, and cosmetic devices.

4. UV and Ozone Resistant LSR

Formulated to resist UV radiation and ozone, these are essential for outdoor electronics, automotive parts, and exterior seals.

Processing Techniques and Their Impact on Material Selection

The processing method significantly influences the choice of LSR. Injection molding remains the most common, but considerations differ depending on the technique:

1. Injection Molding

Requires low-viscosity LSR with specific curing characteristics.

Demands consistent flow properties for complex geometries.

Ideal for high-volume production with precision.

2. Compression Molding

Suitable for small batches or specialized components.

Requires LSR with appropriate viscosity and cure time.

3. Over-molding and Multi-material Assemblies

Demands adhesion compatibility between LSR and other substrates.

Selection of adhesion promoters and surface treatments is crucial.

Expert Tips for Selecting the Optimal Liquid Silicone Rubber

Assess your application's operational environment thoroughly—temperature, chemical exposure, mechanical stress.

Prioritize biocompatibility and regulatory compliance if the product is intended for medical or food contact.

Consult with material suppliers to understand the detailed technical datasheets and processing guidelines.

Perform thorough testing with prototype samples under real-world conditions to validate the chosen LSR.

Consider future scalability—select formulations that can be reliably produced at desired volumes without compromising quality.

Expert Tips for Selecting the Optimal Liquid Silicone Rubber

Assess your application's operational environment thoroughly—temperature, chemical exposure, mechanical stress.

Prioritize biocompatibility and regulatory compliance if the product is intended for medical or food contact.

Consult with material suppliers to understand the detailed technical datasheets and processing guidelines.

Perform thorough testing with prototype samples under real-world conditions to validate the chosen LSR.

Consider future scalability—select formulations that can be reliably produced at desired volumes without compromising quality.

Case Studies: Successful LSR Applications Across Industries

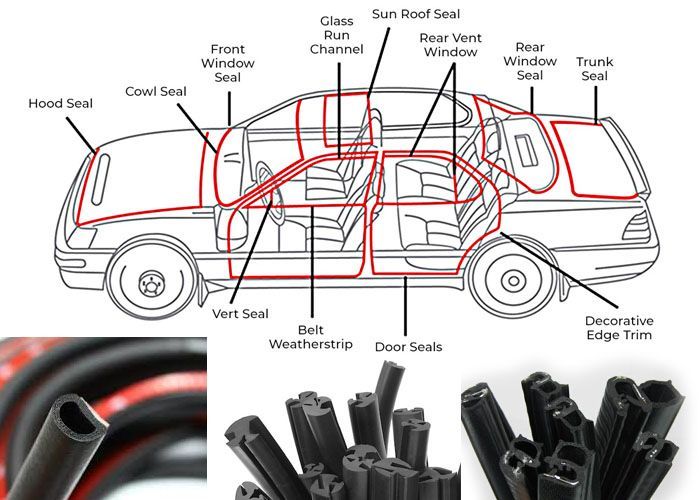

Automotive Industry: High-Temperature Seals

Automotive engines demand high-temperature resistant LSRs that can withstand thermal cycling and chemical exposure. Our high-temp LSR formulations have enabled manufacturers to produce durable seals that improve engine efficiency and longevity.

In Conclusion

Selecting the right Liquid Silicone Rubber (LSR) is a strategic decision that directly impacts your product's performance, durability, and regulatory compliance. By understanding the nuanced differences in material properties, application environments, and processing methods, you can confidently choose an LSR formulation that elevates your manufacturing process and product quality to new heights.

Partner with industry experts, leverage detailed technical insights, and conduct rigorous testing to ensure your choice of LSR aligns perfectly with your application's demands. With the right material, your products will stand out in the marketplace, delivering exceptional value and reliability.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883