How to Achieve Perfect Adhesion in Silicone Overmolding on Metal

- Share

- publisher

- siliconeplus

- Issue Time

- Oct 17,2025

Summary

Achieve flawless silicone-to-metal adhesion through precise surface prep, material selection, and optimized LSR overmolding techniques.

Introduction:

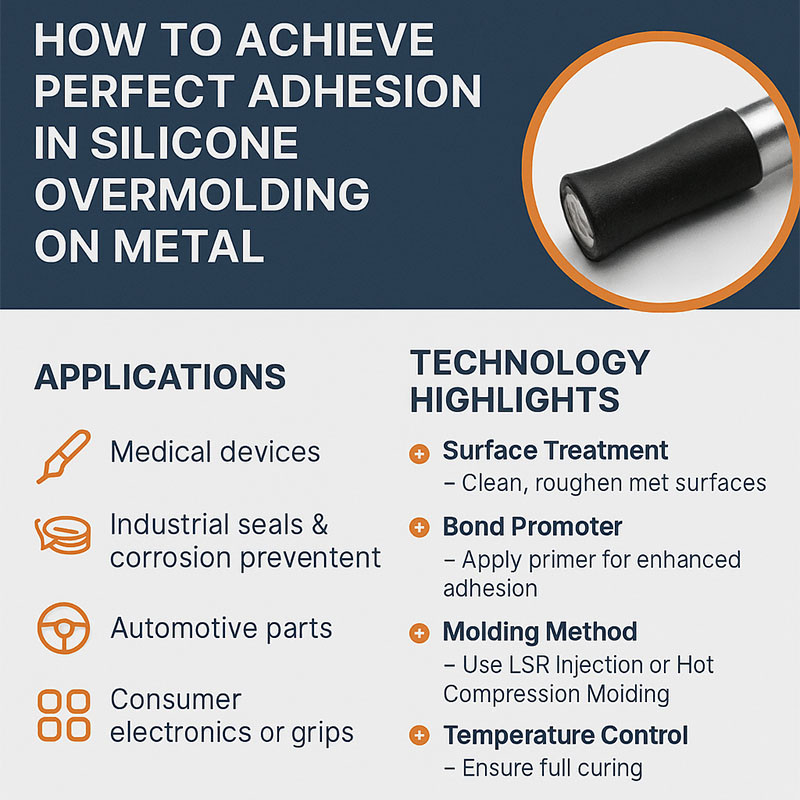

Achieving perfect adhesion when overmolding silicone onto metal is a complex process that demands precision, expertise, and a deep understanding of material interactions. In high-performance applications—ranging from medical devices to electronics, automotive components, and industrial seals—reliable bonding ensures longevity, safety, and optimal functionality. This comprehensive guide provides industry-leading strategies, detailed procedures, and best practices to secure flawless silicone adhesion on diverse metal substrates.

Understanding the Challenges of Silicone Overmolding on Metal

Before diving into methodologies, it is crucial to recognize the inherent challenges:

Surface Incompatibility:

Silicone naturally exhibits low surface energy, causing poor adhesion to metals.Surface Contamination:

Oils, oxides, and dirt significantly impair bonding.Material Mismatch:

Differences in thermal expansion coefficients can induce stress, reducing adhesion over time.Chemical Resistance:

Metals like aluminum, stainless steel, and titanium require specific surface treatments to foster bonding.Addressing these challenges through precise surface preparation and material selection is essential for consistent, high-quality overmolding.

Meticulous Surface Preparation for Optimal Adhesion

Surface preparation is the cornerstone of successful silicone overmolding on metal. Proper cleaning, roughening, and chemical treatments dramatically improve surface energy and bonding strength.

1. Surface Cleaning and Degreasing

Solvent Cleaning: Use isopropyl alcohol (IPA) or detergent solutions to remove oils, greases, and particulates.

Ultrasonic Cleaning:

For intricate parts, ultrasonic baths with suitable cleaning agents ensure thorough removal of contaminants.Drying:

Ensure complete drying to prevent residual moisture, which can hinder adhesion.2. Mechanical Surface Roughening

Abrasive Blasting:

Light sandblasting with alumina or glass beads creates micro-roughness, increasing surface area.Sanding:

Use fine-grit sandpapers (e.g., 400-600 grit) for controlled roughening.Purpose:

Enhances mechanical interlocking between silicone and metal.3. Chemical Surface Treatments

Metal Etching:

Acid etching (e.g., with phosphoric acid) can remove oxides and activate the surface.Silane Coupling Agents:

Applying organosilane primers (e.g., vinyl- or amino-functional silanes) forms a chemical bridge between metal and silicone.Plasma Treatment:

Oxygen plasma or corona discharge treatments increase surface energy without altering the substrate physically.Selection of Compatible Materials and Adhesion Promoters

Material compatibility is vital. Not all silicones bond equally to metals; selecting the right formulation and primers enhances adhesion.

1. Silicone Rubber Selection

Opt for high-quality, medical-grade or industrial-grade silicones with proven adhesion properties.

Consider addition-cure silicones over condensation-cure silicones, as they tend to have fewer by-products that interfere with bonding.

2. Use of Adhesion Promoters and Primers

Silane-based primers are the industry standard for promoting adhesion.

Select primers compatible with both the silicone formulation and the specific metal substrate.

Follow manufacturer instructions precisely for application and curing times.

Advanced Overmolding Techniques for Superior Bonding

Proper technique execution is essential for achieving consistent, durable adhesion.

1. Mold Design and Material Compatibility

Use precise mold designs that prevent air entrapment.

Ensure mold surfaces are clean and free of residues.

Consider specialized mold coatings that facilitate silicone release and adhesion.

2. Controlled Processing Conditions

Temperature Control:

Maintain optimal mold and material temperatures as specified by silicone manufacturer.Injection Pressure:

Use appropriate pressure to ensure complete cavity fill without causing surface defects.Curing Parameters:

Follow recommended curing times and conditions, whether room temperature or elevated temperature curing.3. Post-Overmolding Surface Treatments

Surface Activation:

Light flame treatment or corona discharge immediately before overmolding can further increase surface energy.Adhesion Testing:

Perform peel and shear tests to verify bond strength during process development.Quality Control and Testing for Long-Term Bond Durability

Ensuring long-term adhesion stability requires rigorous testing:

| Test Type | Purpose | Methodology | Acceptance Criteria |

| Peel Test | Measure adhesion strength | Peel the silicone from metal substrate | Minimum adhesion strength as per specifications |

| Shear Test | Evaluate bond shear strength | Apply shear force until failure | Consistent failure within silicone or at interface |

| Environmental Testing | Assess durability under conditions | Exposure to humidity, temperature cycling, chemicals | No delamination or significant strength reduction |

Case Study: Overmolding Silicone on Aluminum for Medical Devices

Scenario: Achieving durable silicone bonding on aluminum components used in medical implants.

Approach:

Thorough cleaning with IPA and ultrasonic cleaning.

Light abrasive blasting with alumina particles to create micro-roughness.

Application of a specialized silane primer designed for aluminum surfaces.

Use of addition-cure, high-purity silicone with proven adhesion properties.

Precise temperature control during injection molding.

Post-molding oxygen plasma treatment to enhance surface energy.

Rigorous peel and shear testing confirming bond strength exceeds industry standards.

Outcome: Long-lasting, biocompatible silicone overmolds with excellent adhesion and mechanical integrity, meeting all medical regulatory requirements.

Summary: Best Practices for Flawless Silicone Overmolding on Metal

Prioritize meticulous surface preparation—cleaning, roughening, and chemical activation.

Select compatible silicone formulations and leverage proven adhesion promoters.

Design molds and process parameters to optimize flow, fill, and curing.

Implement rigorous quality control through standardized testing.

Maintain a controlled environment to prevent contamination and variability.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883

Final Remarks

Achieving perfect adhesion in silicone overmolding on metal requires a holistic approach—combining precise surface treatment, material selection, optimized processing, and rigorous testing. By adhering to these industry best practices, manufacturers can produce high-performance, durable components that meet or exceed application demands, ensuring long-term reliability and customer satisfaction.