How Well Does Silicone Stick to Metal? | Siliconeplus Silicone Bonding Solutions

- Share

- publisher

- Siliconeplus Editor

- Issue Time

- Feb 19,2025

Summary

Discover how silicone bonds with metal and the best silicone sealant solutions for metal surfaces. Learn about silicone's durability, adhesion, and applications at Siliconeplus.

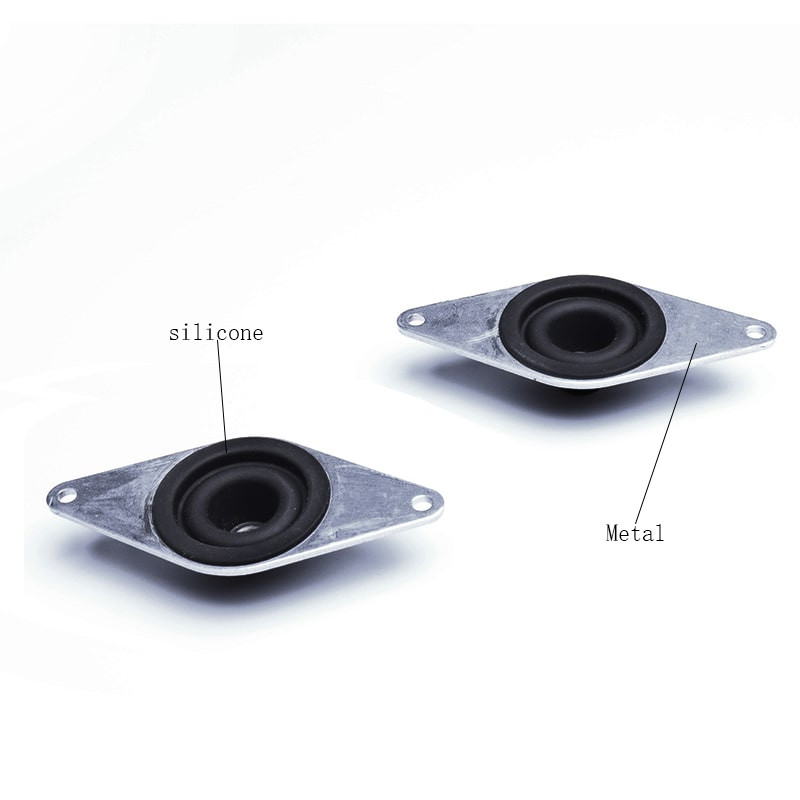

Silicone, known for its versatility and wide range of applications, is frequently used to bond with various materials. When it comes to metal, the question of how well silicone adheres can be crucial for many industries, from automotive to electronics and construction. But does silicone actually stick to metal effectively? Let's explore the factors that influence silicone's bond with metal and what you need to consider to achieve the best results.

Understanding Silicone's Adhesion to Metal

Silicone, by nature, is a non-porous material, and metal is typically smooth, making it more challenging for adhesives to form a strong bond without proper preparation. Unlike other materials, metal doesn't naturally allow substances like silicone to bond easily. However, with the right kind of silicone and surface preparation, it is entirely possible for silicone to bond effectively with metal.

Factors Affecting Silicone's Adhesion to Metal

Surface Preparation

The metal surface must be clean and free of any contaminants such as grease, oil, dirt, or rust. Even small traces of impurities can weaken the bond between silicone and metal. To achieve a strong adhesion, the metal should be thoroughly cleaned and, in some cases, lightly sanded or roughed up. This increases the surface area and provides more grip for the silicone.

Silicone Type

Not all silicones are created equal. For instance, RTV (Room Temperature Vulcanizing) silicone is widely used for bonding metal due to its excellent adhesion properties and flexibility. Choosing the correct silicone type—whether it's for high-temperature resistance, waterproofing, or flexibility—is crucial for successful bonding with metal surfaces.

Curing Process

The curing time for silicone can also influence its adhesion. Some silicones cure faster than others, and it is important to allow adequate curing time for the best results. Also, keep in mind that the curing process can be affected by the environmental conditions, such as temperature and humidity.

Metal Type

Different metals have different properties, and some may bond more effectively with silicone than others. For example, metals like aluminum or stainless steel, which have smoother surfaces, may require additional steps like priming to ensure a secure bond. On the other hand, metals like galvanized steel or cast iron, which have a more textured surface, might offer better natural adhesion.

Enhancing Silicone's Bond with Metal

To improve silicone's ability to stick to metal, it may be helpful to use a primer designed specifically for metal bonding. Primers create a bonding layer that helps the silicone adhere better to the metal surface. Additionally, applying silicone to metal surfaces under optimal conditions—clean, dry, and at the right temperature—can ensure a stronger and more reliable bond.

The Bottom Line

Silicone can stick to metal, but its effectiveness depends on factors like surface preparation, the type of silicone used, and environmental conditions. By understanding these elements and taking the necessary steps to ensure proper bonding, silicone can form a durable and long-lasting bond with metal surfaces. Whether you're sealing, waterproofing, or creating flexible joints, the right combination of silicone and metal preparation will provide reliable results.

If you're looking for a specific silicone solution for your metal bonding needs, feel free to reach out for expert advice and customized recommendations.