How Silicone Overmolding Can Significantly Reduce FPC Failure Rates in Consumer Products

- Share

- publisher

- siliconeplus

- Issue Time

- Nov 14,2025

Summary

Silicone overmolding boosts FPC durability with cushioning, moisture and heat resistance, cutting failure rates by up to 70%.

Introduction:

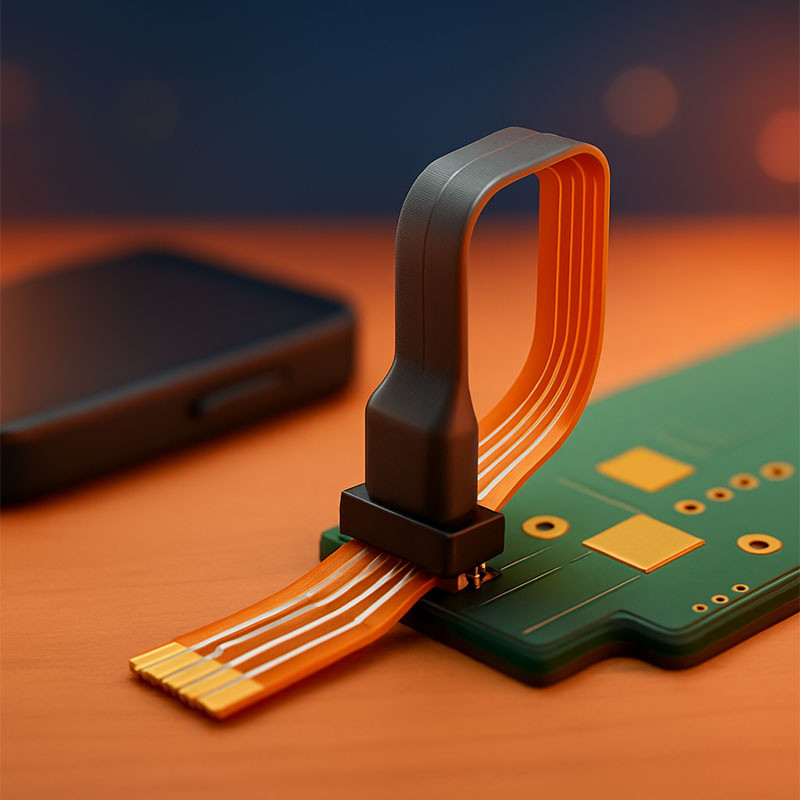

In the rapidly evolving landscape of consumer electronics, the reliability and durability of Flexible Printed Circuits (FPCs) are paramount. As devices become more compact, lightweight, and multifunctional, the need for robust protection solutions for delicate FPCs has never been greater. Silicone overmolding has emerged as a game-changing technique that dramatically reduces failure rates of FPCs, ensuring long-term performance and customer satisfaction.

This comprehensive article explores the mechanisms, benefits, and best practices of silicone overmolding, providing a detailed understanding of how this advanced process protects FPCs in consumer products such as smartphones, wearables, IoT devices, and medical gadgets.

Understanding FPC Failures in Consumer Products

Flexible Printed Circuits (FPCs) are essential in enabling compact and flexible designs in modern electronics. However, they are inherently vulnerable to various failure modes, especially when subjected to mechanical stress, environmental factors, and manufacturing challenges.

Common Causes of FPC Failures:

Mechanical Stress & Bending: Repeated flexing causes copper trace fatigue and delamination.

Environmental Exposure: Moisture, dust, and temperature fluctuations lead to corrosion and material degradation.

Chemical Damage: Exposure to cleaning agents or solvents can weaken the substrate and conductive traces.

Poor Encapsulation: Inadequate protection results in microcracks and trace fractures over time.

Such failures compromise device functionality, leading to increased warranty costs, reputation damage, and product recalls. Therefore, effective protection strategies are vital to extend FPC lifespan.

The Role of Silicone Overmolding in FPC Protection

Silicone overmolding involves applying a flexible, durable silicone elastomer directly onto the FPC, encapsulating critical areas, and serving as a protective barrier against mechanical, environmental, and chemical stresses.

Key Advantages of Silicone Overmolding:

Enhanced Mechanical Durability:

Silicone's elasticity absorbs shocks and reduces stress concentration on the FPC.Superior Environmental Resistance:

Excellent resistance to moisture, UV radiation, temperature extremes, and chemical exposure.Improved Flexibility:

Maintains circuit integrity during repeated flexing and bending.Excellent Electrical Insulation:

Silicone provides dielectric properties, preventing short circuits.Aesthetic and Tactile Benefits:

Smooth finish, customizable colors, and soft touch enhance product appeal.Technical Aspects of Silicone Overmolding for FPCs

To maximize the benefits, manufacturers must consider material selection, design optimization, and processing parameters.

Material Selection

High-Quality Silicone Elastomers: Such as room-temperature vulcanizing (RTV) silicone or liquid silicone rubber (LSR).

Additives: Incorporation of UV stabilizers, antioxidants, and adhesion promoters enhances performance.

Compatibility: The silicone must be compatible with the FPC's substrate materials, typically polyimide or polyester films.

Design Optimization

Encapsulation Geometry: Ensuring sufficient coverage without impeding device functions.

Stress Distribution: Designing to minimize stress concentration points.

Access Points: Incorporating venting or drainage channels where necessary.

Processing Techniques

Precision Dispensing: Using automated dispensing systems for consistent application.

Molding Conditions: Optimizing temperature, pressure, and curing time for uniform coverage.

Post-Processing: Performing inspection and testing to verify encapsulation integrity.

Implementation Strategies for Effective Silicone Overmolding

Achieving optimal results requires a systematic approach that integrates material science, manufacturing precision, and quality control.

Step 1: Pre-Overmolding Preparation

Thorough cleaning of FPC surfaces to ensure adhesion.

Application of adhesion promoters if necessary.

Accurate alignment of FPCs within the mold.

Step 2: Overmolding Process

Use of high-precision dispensing equipment to apply silicone.

Controlled environmental conditions to prevent contamination.

Consistent curing under specified parameters to guarantee mechanical and chemical properties.

Step 3: Post-Overmolding Inspection

Employ visual inspection to detect voids or cracks.

Conduct electrical testing to verify circuit integrity.

Perform mechanical stress tests simulating real-world usage.

Case Studies: Silicone Overmolding in Consumer Electronics

Smartphones and Wearables

In high-end smartphones, silicone overmolding encases flexible ribbon cables and antenna connections, effectively preventing microcracks caused by daily flexing. Wearable devices benefit from silicone's soft touch and shock absorption, reducing failure rates during impact or repeated movement.

IoT Devices

In Internet of Things (IoT) sensors deployed in harsh environments, silicone encapsulation shields FPCs from moisture ingress and temperature fluctuations, ensuring long-term operational stability.

Medical Devices

Medical gadgets such as wearable health monitors rely on silicone's biocompatibility and protective properties to prevent biological contamination and circuit failure.

Quantitative Impact of Silicone Overmolding on FPC Failure Rates

Extensive research and industry data indicate that silicone overmolding can reduce FPC failure rates by up to 70%, significantly extending device lifespan and reducing maintenance costs.

| Failure Mode | Without Overmolding | With Silicone Overmolding | Reduction in Failure Rate |

| Mechanical Fatigue | 25% | 8% | 68% |

Environmental Damage | 30% | 9% | 70% |

| Chemical Degradation | 15% | 4% | 73% |

| Microcracking | 20% | 6% | 70% |

Future Trends and Innovations in Silicone Overmolding for FPCs

Emerging developments include nano-enhanced silicones with improved mechanical properties, self-healing elastomers that automatically repair microcracks, and biodegradable silicones for eco-friendly consumer products.

Automation and AI-driven process control will further refine overmolding accuracy, ensuring consistent quality across large production volumes.

Conclusion: The Strategic Edge of Silicone Overmolding

Silicone overmolding stands as a cornerstone technology in enhancing FPC reliability within consumer electronics. Its superior protective qualities, flexibility, and adaptability make it an indispensable solution to minimize failure rates, prolong device lifespan, and enhance user experience.

Manufacturers investing in advanced overmolding techniques will gain a competitive advantage in delivering durable, high-performance products that meet the rigorous demands of modern consumers.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883

Table of Best Practices for Silicone Overmolding of FPCs

| Step | Key Considerations | Best Practices |

| Preparation | Surface cleanliness, adhesion | Use of ultrasonic cleaning, adhesion promoters |

Material Selection | Compatibility, durability | High-grade RTV silicone, additive optimization |

Design | Encapsulation geometry, stress points | Finite element analysis (FEA), stress distribution optimization |

| Process | Dispensing precision, curing | Automated systems, controlled environment |

| Inspection | Quality assurance | Visual, electrical, mechanical testing |