How Liquid Silicone Rubber (LSR) Solutions from SiliconePlus Can Benefit Your Business

- Share

- publisher

- siliconeplus

- Issue Time

- Sep 22,2025

Summary

SiliconePlus delivers custom LSR molding solutions for medical, automotive, beauty & wearable industries with safety.

What to Expect with Medical Grade & Industrial LSR Solutions

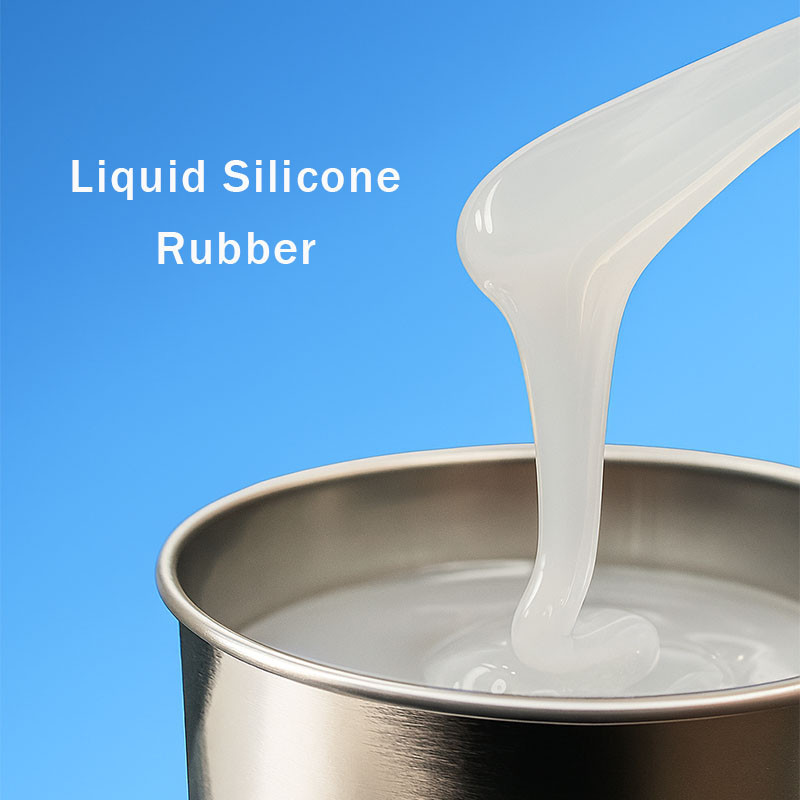

Companies across industries — from healthcare and automotive to beauty and wearable technologies — are constantly searching for reliable materials that deliver superior performance, regulatory compliance, and cost efficiency. Traditional rubber materials often fall short when it comes to biocompatibility, durability, and resistance to extreme environments. That’s where Liquid Silicone Rubber (LSR) comes in.

At SiliconePlus, we specialize in custom precision LSR injection molding and FDA-approved silicone solutions. Our expertise allows us to design and manufacture parts that not only meet but exceed the stringent requirements of medical devices, automotive components, beauty tools, and wearable technologies.

With customizable durometers, advanced curing processes, and ISO-certified facilities, we provide our clients the confidence to bring innovative and compliant products to market faster.

The Importance of LSR Across Industries — expanded detail

Below I’ve expanded the “Importance of LSR Across Industries” section with practical, technical, and commercial detail you can drop into web copy, proposals, or RFQs.

Why it matters: Medical devices demand biocompatibility, predictable performance after sterilization, and extremely low extractables/contamination. LSR can be formulated to meet stringent biocompatibility testing (e.g., ISO 10993 / USP Class VI — formulation- and supplier-dependent) and is routinely used where skin or tissue contact occurs.

Key strengths

: Excellent resistance to common sterilization methods (autoclave/steam, EtO, and many gamma protocols depending on formulation), low particulate generation when processed in closed LSR systems, and minimal change in mechanical properties after sterilization cycles.Typical medical uses:

Respiratory masks, seals & gaskets, tubing connectors, catheter components, implantable housings (implantable only with specific implant-grade LSR and testing), syringe parts, load-bearing seals.

Design & compliance notes:

Choose implant vs. external-contact grades deliberately; work with suppliers to obtain biocompatibility and sterilization validation data for your specific part and intended use.

Why it matters: Automotive environments expose parts to heat, oils, fuels, road chemicals, and mechanical stress. LSR’s thermal stability and chemical resistance make it ideal for under-hood and exterior applications.

Key strengths:

Wide operating temperature range (formulation-dependent, commonly from well below freezing to ~+150–200°C), excellent resistance to oils, greases, and many automotive fluids, good vibration and sealing performance.

Typical automotive uses: Gaskets & O-rings, protective boots, cable sheaths, sensor grommets, vibration-damping mounts, weather seals, key fobs and soft-touch interior components.

Design & production:

LSR overmolding onto plastics/metal inserts and tight-tolerance multi-cavity molding are common. Consider durometer selection for sealing vs. cushioning functions.

Why it matters: Products that contact skin must be safe, comfortable, and easy to clean while offering appealing tactile and visual qualities.

Key strengths:

Skin-friendly (low irritation potential), easy to color or keep translucent/clear, excellent feel (soft-touch finishes), and durable across repeated cleaning/chemical exposure.Typical uses:

Facial brush heads, applicators, makeup tools, hygienic handles, reusable beauty pads, seals for cosmetic dispensers.Consumer advantage:

LSR gives premium tactile feel and longevity compared with many thermoplastics — fewer replacements, better hygiene.Why it matters:

Wearables require comfort, flexibility, environmental resistance, and electrical insulation — all areas where LSR performs well.Key strengths:

Flexible at low durometers, comfortable against skin for long wear, good dielectric properties, UV and sweat resistance, durable against flex fatigue.Typical uses:

Watch straps, sensor housings, soft buttons, sealing gaskets for water resistance, overmolded grips and interfaces.Manufacturing benefits:

Thin-wall LSR injection molding enables fine details (labels, micro-textures) and consistent soft-touch surfaces with high repeatability.Industrial & Other Applications (consumer, food contact, lighting, etc.)

Why it matters:

LSR’s chemical stability, thermal range, and ability to form precision seals make it useful beyond the big four industries.Key strengths:

Low shrinkage, dimensional stability, flame-retardant and electrical insulation options, and the possibility of food-contact grades.Typical uses:

Food-contact seals, lighting gaskets, industrial vibration dampers, consumer goods components.Material Properties, Standards & Testing (practical summary)

Mechanical properties:

Durometers commonly range from ~10–80 Shore A (select per application); LSR offers good tensile strength, tear resistance, and low permanent deformation (compression set).Environmental resistance:

Good ozone and UV resistance, chemical and disinfectant resistance (alcohols, dilute bleaches — check compatibility), and stability over broad temperatures.Regulatory:

Medical- and food-contact-compatible LSR grades are available; validate via supplier certificates and specific test reports (e.g., biocompatibility, extractables, sterilization validation).Manufacturing cleanliness:

LSR tooling often runs in closed, automated systems compatible with cleanroom assembly — important for medical and high-reliability electronics.Manufacturing & Business Advantages

Design freedom:

Low-viscosity LSR fills thin walls and intricate features, enabling integrated seals, soft-touch features, and fine logos/textures without secondary finishing.Process efficiency:

Fast cure cycles in modern LSR presses, high automation potential, low scrap rates — lowers unit cost at scale.Branding & product differentiation:

Overmolding, multi-shot, and in-mold marking allow logos, colors, and tactile branding to be integrated into parts.Lifecycle & sustainability:

Longer product life and chemical/UV durability can reduce replacements and waste — an indirect sustainability benefit.Performance Advantages of LSR from SiliconePlus

Liquid silicone rubber offers unmatched properties that outperform many conventional materials:

Biocompatibility

– safe for human contact and implant applicationsSterilization compatibility

– withstands autoclaving, chemicals, and disinfectantsTemperature resistance

– performs reliably under extreme heat or coldDurability

– excellent tensile strength, hardness, and compression setFluid and chemical resistance

– ensuring longer product lifecyclesExposure Categories of LSR in Medical & Industrial Use

1.Limited Exposure: Short-term contact with skin or mucosal surfaces (<24h).

2.Prolonged Exposure: Long-term contact (up to 30 days), tested for toxicity and biocompatibility.

3.Permanent Exposure: Implant-grade solutions suitable for continuous long-term use.

Why Partner with SiliconePlus

1.At SiliconePlus, we combine precision LSR molding with cost-efficient production to give our clients a true competitive edge.

2.Custom Mold Design & Overmolding: Optimized for high-volume, streamlined manufacturing.

3.Brand Customization: Add company logos, names, or colors for product differentiation.

4.Prototyping & Mass Production: Validate your design before scaling up.

5.Cross-Industry Expertise: Serving medical, automotive, beauty, and wearable applications.

By reducing unnecessary processing steps and using advanced LSR overmolding, we minimize costs while maximizing product functionality and quality.

Driving Innovation with SiliconePlus

The industries we serve are evolving rapidly — and so are the expectations for high-performance materials. With SiliconePlus LSR solutions, you can count on:

1.Consistent precision and repeatability

2.Faster time-to-market with cost savings on assembly

3.Access to various LSR blends and durometers to meet exact requirements

Whether you need a biocompatible medical component, a heat-resistant automotive part, or a durable wearable accessory, our LSR molding expertise ensures your products stay ahead of industry standards.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883