How LSR Enhances the User Experience in Wearables and Medical Devices

- Share

- publisher

- siliconeplus

- Issue Time

- Sep 3,2025

Summary

LSR enhances wearables and medical devices with comfort, durability, and precision molding for superior user experience.

Introduction:The Critical Role of Material Innovation in Wearable and Medical Device Design

In the rapidly evolving landscape of wearable technology and medical devices, the choice of materials profoundly influences user experience, device performance, and regulatory compliance. Among the most significant breakthroughs in recent years is the application of **Liquid Silicone Rubber (LSR)**—a high-performance, versatile material that addresses longstanding challenges in device design, comfort, and functionality.

As industry leaders in material science and medical-grade manufacturing, we recognize that LSR is not merely a raw material but a transformational component that elevates user interaction, device longevity, and clinical efficacy. This comprehensive exploration underscores how LSR profoundly enhances the user experience in wearables and medical devices, setting new standards for comfort, durability, and technological integration.

Understanding Liquid Silicone Rubber (LSR): The Foundation of Enhanced User Experience

Liquid Silicone Rubber (LSR) is a highly specialized elastomer characterized by exceptional flexibility, biocompatibility, and resistance to environmental factors. Its liquid form allows for precision molding, enabling the production of complex, ergonomically optimized components that conform seamlessly to the human body.

Key Properties of LSR That Drive User-Centric Design

1.Superior Comfort and Flexibility:

LSR's silky-smooth texture and elastic properties provide unmatched comfort for prolonged wear, reducing skin irritation and pressure points.

2.Biocompatibility and Medical Certification:

Certified as medical-grade silicone, LSR ensures safe contact with skin and mucous membranes, meeting rigorous ISO 10993 standards.

3.Durability and Resistance:

Resistant to UV radiation, ozone, temperature fluctuations, and chemical exposure, LSR maintains consistent performance over extended periods.

4.Ease of Manufacturing:

The liquid form enables high-precision molding, resulting in complex geometries and integrated features that enhance device ergonomics.

Revolutionizing Wearable Devices with LSR: The Path to Superior User Experience

Ergonomic Design and Fit

Wearables, such as smartwatches, fitness trackers, and medical monitoring patches, demand ergonomic designs that fit snugly without causing discomfort. LSR's flexibility and elasticity allow manufacturers to produce contoured, skin-friendly straps and casings that adapt perfectly to diverse body shapes.

Enhanced Comfort for Long-Term Use

Prolonged device usage necessitates materials that minimize skin irritation. LSR's breathable, soft surface ensures comfortable contact, even during extended periods, significantly improving adherence to medical and fitness routines.

Seamless Water and Sweat Resistance

LSR's hydrophobic nature provides excellent water resistance, enabling wearables to operate reliably during water-based activities or sweaty conditions. This reliability directly correlates to user satisfaction and continuous health monitoring.

Aesthetic and Tactile Appeal

The smooth finish of LSR components enhances the visual appeal and tactile experience of devices, making them more inviting and user-friendly.

Medical Devices: How LSR Elevates Safety, Efficacy, and Patient Comfort

1.Biocompatibility and Safety

In medical applications, material safety is paramount. LSR's biocompatibility ensures safe, non-reactive contact with skin, mucous membranes, and internal tissues. Its compliance with international standards makes it ideal for implantable and external medical devices.

2.Designing Complex, Patient-Centric Devices

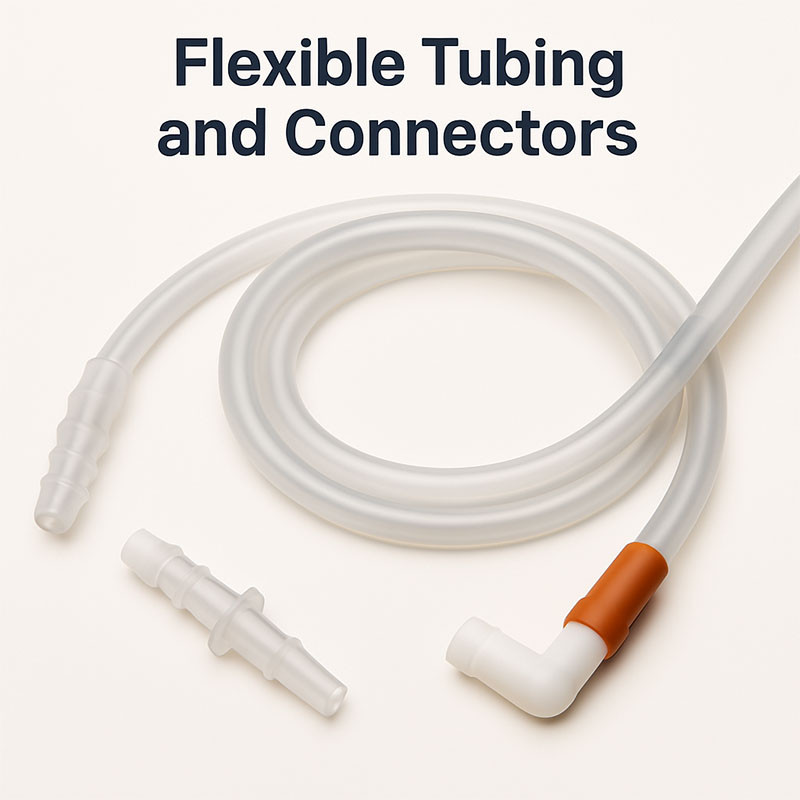

LSR's liquid molding process facilitates the creation of complex geometries—such as catheter covers, sensor housings, and prosthetic interfaces—that maximize patient comfort and clinical accuracy.

3.Durability in Medical Environments

Devices made with LSR withstand sterilization processes like autoclaving and gamma radiation, ensuring long-term usability without degradation, which is critical for cost-effective healthcare solutions.

4.Reducing Infection Risks

The non-porous surface of LSR minimizes bacterial adhesion, reducing infection risks associated with medical contact devices.

Innovative Applications of LSR in Wearables and Medical Devices

Innovative Applications of LSR in Wearables and Medical Devices

| Application Area | Description | Benefits |

Flexible Sensor Encapsulation | Encasing sensors in LSR to provide stretchability and skin contact | Improved sensor accuracy, patient comfort |

| Ergonomic Straps and Casings | Using LSR for contoured wearable straps | Better fit, enhanced user compliance |

| Medical Patch Devices | Incorporating LSR in adhesive patches for drug delivery or health monitoring | Comfort, reliability, minimal skin irritation |

| Prosthetic and Orthopedic Components | Fabricating custom-fit prosthetics using LSR | Enhanced fit, functionality, and patient comfort |

Manufacturing Innovations: How LSR Elevates Device Quality and Scalability

1.Precision Molding and Complex Geometries

ding and Complex GeometriesLSR's liquid injection molding allows for high-resolution, repeatable manufacturing of complex features like integrated seals, soft-touch surfaces, and fine detail—ensuring consistent quality across large production volumes.

2.Rapid Prototyping and Customization

The versatility of LSR supports rapid prototyping, enabling fast iterations that accelerate product development cycles. Custom-fit solutions are achievable with minimal tooling costs, offering personalized healthcare devices.

3.Enhanced Durability and Environmental Resistance

LSR components exhibit superior resistance to UV, ozone, temperature extremes, and chemical exposure, reducing failure rates and maintenance costs.

Future Trends: LSR as a Catalyst for Next-Generation Wearables and Medical Devices

Smart, Adaptive Materials:

Integration of sensors within LSR to create self-monitoring devices that adapt to environmental changes.Miniaturization and Complex Integration: Using LSR to develop compact, multi-functional devices with embedded electronics and biocompatible interfaces.Sustainability and Eco-Friendliness:

Innovations in LSR formulations to support recyclability and biodegradability, aligning with sustainable healthcare goals.

Conclusion:LSR as the Cornerstone of Superior User Experience in Wearables and Medical Devices

Liquid Silicone Rubber (LSR) stands at the forefront of material innovation, fundamentally transforming the design, performance, and user experience of wearable and medical devices. Its biocompatibility, flexibility, durability, and manufacturing versatility enable device manufacturers to create more comfortable, reliable, and aesthetically appealing products that meet the highest standards of clinical safety and user satisfaction.

As the healthcare and wearable technology markets continue to grow and evolve, LSR will remain an indispensable material, unlocking new possibilities for personalized healthcare, patient comfort, and technological innovation. Embracing LSR is not merely an option but a strategic imperative for companies aiming to lead the future of high-performance, user-centric devices.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883