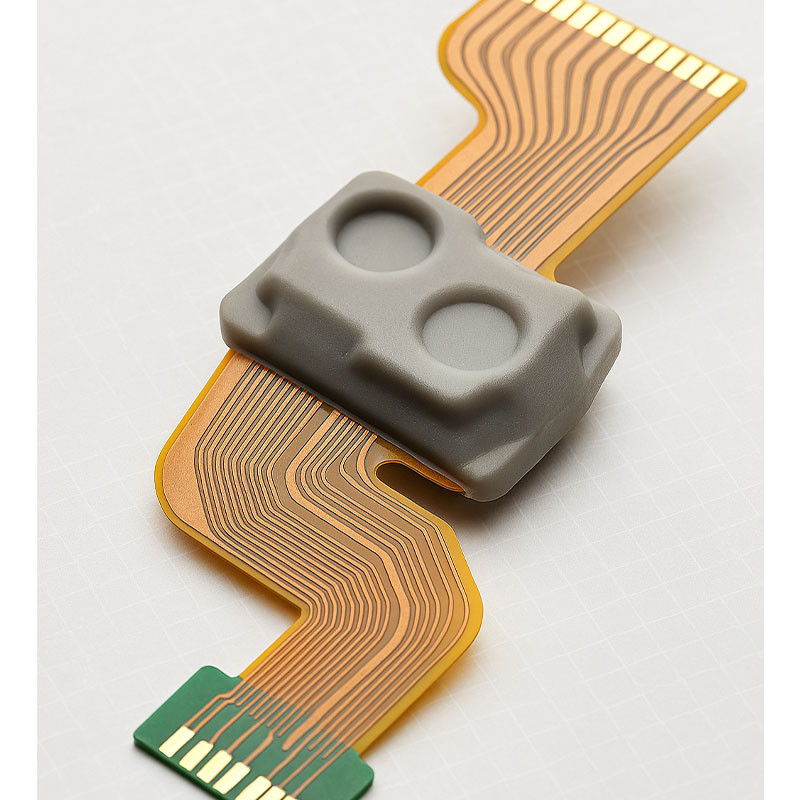

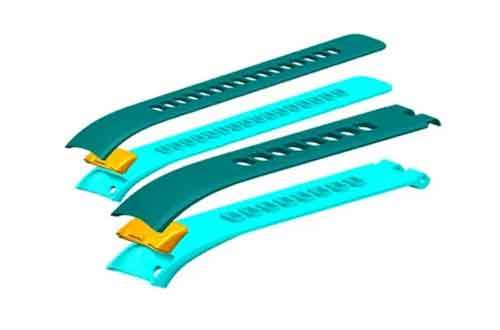

Case Study: FPC with Silicone Overmolding in High-Performance Industrial Equipment

- Share

- publisher

- siliconeplus

- Issue Time

- Nov 3,2025

Summary

Explore how silicone overmolding enhances FPC durability, and protection in industrial electronics for extreme environments.

Introduction: Elevating Industrial Equipment Reliability with Advanced FPC Solutions

In the realm of high-performance industrial equipment, the demand for robust, reliable, and flexible electronic components has never been greater. As machinery operates in extreme environments, from high temperatures to aggressive chemical exposure, the traditional rigid circuit boards often fall short in ensuring long-term durability.

This comprehensive case study explores the integration of Flexible Printed Circuits (FPC) with silicone overmolding, a groundbreaking approach that significantly enhances mechanical resilience, environmental sealing, and electrical performance. Our focus is on delivering insights into design considerations, material selection, manufacturing processes, and real-world applications that position this technology as the optimal solution for high-performance industrial equipment.

Understanding Flexible Printed Circuits (FPC): The Foundation of Innovation

Flexible Printed Circuits are thin, lightweight, and highly adaptable electronic substrates that facilitate complex circuit integration within constrained spaces. Their flexibility allows for dynamic movement and vibration absorption, making them ideal for industrial machinery subjected to mechanical stress.

Key Advantages of FPC in Industrial Applications

Space-Saving Design:

FPCs enable compact circuit layouts, reducing overall equipment footprint.Enhanced Flexibility:

Accommodate bending, twisting, and folding without compromising electrical integrity.Reduced Weight:

Significantly lighter than traditional rigid PCBs, contributing to lower equipment weight and improved portability.High-Density Interconnects:

Support dense component placement, facilitating advanced functionality in limited spaces.Cost-Effective Manufacturing:

When designed efficiently, FPC fabrication offers cost savings in mass production.Challenges in Industrial Environments: Why Standard FPCs Need Reinforcement

While FPC technology offers numerous benefits, industrial environments pose unique challenges such as:

Exposure to Moisture, Dust, and Chemicals: Leading to corrosion and electrical failures.

Vibration and Mechanical Shock: Causing circuit fatigue or breakage.

Temperature Extremes: Resulting in material degradation or delamination.

Need for Long-Term Reliability: Critical in applications where maintenance is costly or impractical.

To overcome these hurdles, additional protective measures are necessary. Silicone overmolding emerges as an effective solution for protecting FPCs against these adverse conditions.

Silicone Overmolding: Revolutionizing FPC Durability

Silicone overmolding involves encasing the FPC with a silicone elastomer layer, creating a protective, flexible, and chemically resistant barrier. This process integrates seamlessly with the FPC manufacturing workflow, offering multiple benefits:

Superior Environmental Sealing:

Protects against moisture, dust, chemicals, and UV exposure.Enhanced Mechanical Strength:

Absorbs shocks, vibrations, and flexural stresses.Temperature Resistance:

Maintains flexibility and performance across a broad temperature range (-55°C to +250°C).Electrical Insulation:

Provides an effective dielectric barrier, preventing short circuits.Longevity:

Extends service life of the FPC in harsh operating conditions.Design Considerations for FPC with Silicone Overmolding

Optimizing the design of FPCs for silicone overmolding requires meticulous planning:

Material Selection

FPC Substrate: Typically polyimide or polyester films for high thermal stability and dimensional stability.

Conductive Layers: Copper foil with appropriate adhesion promoters.

Silicone Elastomer: Platinum-cure or tin-cure silicone formulations with low viscosity for easy molding and good adhesion.

Component Placement and Routing

Strategic Routing: Minimize sharp bends and stress concentration points.

Component Placement: Position sensitive components away from overmolding edges to prevent damage during sealing.

Pad Design: Use larger pad areas and specialized surface finishes to ensure strong adhesion between the silicone and conductive traces.

Overmolding Process Parameters

Mold Design: Precise molds that conform to the FPC shape, ensuring uniform coverage.

Curing Conditions: Controlled temperature and curing times to prevent material shrinkage and delamination.

Surface Preparation: Adequate cleaning and surface treatment to promote strong silicone-FPC bonding.

Manufacturing Process Workflow

FPC Fabrication:

High-precision etching, lamination, and component placement.Surface Treatment:

Application of adhesion promoters on the FPC surface.Mold Preparation:

Design of custom molds to encapsulate the FPC with silicone.Overmolding:

Injection of silicone elastomer into molds, ensuring full coverage of critical areas.Curing:

Controlled thermal curing to achieve optimal elastomer properties.Post-Processing:

Inspection, testing, and integration into industrial equipment.Application Case Study: High-Performance Industrial Robotics

In a recent deployment, FPCs with silicone overmolding were integrated into industrial robotic arms operating in extreme conditions:

Operational Environment:

High temperatures (>85°C), exposure to lubricants, dust, and mechanical shocks.Design Goals:

Ensure long-term reliability, flexibility, and environmental protection.Outcome:

The silicone overmolded FPCs demonstrated exceptional performance, withstanding vibration cycles exceeding 1 million, maintaining signal integrity, and preventing corrosion.Advantages Over Traditional Protection Methods

Feature | Silicone Overmolding | Conformal Coatings | Rigid Encapsulation |

Flexibility | High | Low | Low |

| Environmental Sealing | Excellent | Good | Moderate |

Vibration Resistance | Superior | Moderate | Limited |

| Temperature Range | Broad (-55°C to +250°C) | Narrow | Limited |

| Manufacturing Complexity | Moderate | Low | High |

| Long-Term Durability | Exceptional | Moderate | Limited |

Future Trends and Innovations

The evolution of smart materials and advanced manufacturing techniques will further enhance the performance and integration of FPCs with silicone overmolding:

Nanocomposite Silicone Elastomers: Offering improved mechanical properties and self-healing capabilities.

3D Printing of Overmolding Molds: Allowing rapid prototyping and complex geometries.

Embedded Sensors: Integration within the silicone layer for real-time health monitoring.

Hybrid Material Systems: Combining silicone with other elastomers for tailored properties.

Conclusion: A Game-Changer for Industrial Electronics

The integration of Flexible Printed Circuits with silicone overmolding represents a paradigm shift in designing durable, flexible, and environmentally resilient electronic components for high-performance industrial equipment. This technology ensures unmatched protection against harsh conditions, mechanical stresses, and long-term operational challenges.

By adopting this advanced approach, manufacturers can significantly improve the reliability, reduce maintenance costs, and extend the lifespan of critical electronic systems within extreme industrial environments. The ongoing innovations promise even greater performance enhancements, positioning silicone-overmolded FPCs as the standard solution for next-generation industrial electronics.

About Us

We are a leading provider of customized flexible printed circuit solutions with expertise in silicone overmolding technology. Our team is dedicated to delivering innovative, reliable, and high-quality electronic components tailored to the unique needs of industrial applications worldwide. With state-of-the-art manufacturing facilities and a focus on quality assurance, we ensure our clients stay ahead in the demanding landscape of industrial electronics.

Contact Us

For more information on custom FPC with silicone overmolding solutions, please contact our technical team. We provide comprehensive consulting, design support, and manufacturing services to meet your specific application requirements.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883