Beyond the Mold: How Customization and Precision Molding Define Excellence in Silicone Rubber Products

- Share

- Issue Time

- Sep 29,2025

Summary

In modern manufacturing, one-size-fits-all solutions fall short. This article explores the critical role of customization and precision molding in creating high-performance silicone rubber products. We delve into the advanced techniques, material science, and quality control processes that enable manufacturers to deliver tailored solutions for demanding industries like medical, automotive, and electronics, highlighting how precision translates to superior functionality, durability, and value.

The Unseen Excellence: Why Custom Precision Molding is a Game-Changer for Silicone Rubber Products

In a world driven by innovation, the demand for highly specific, complex, and reliable components has never been greater. Off-the-shelf parts often fall short, forcing industries to seek manufacturers who can turn a precise vision into a tangible reality. This is where the synergy of customization and precision molding comes to the forefront, especially for a versatile material like silicone rubber. As a leader in silicone rubber product manufacturing, we leverage these advanced processes to engineer solutions that offer unparalleled performance, durability, and quality. From intricate medical devices to robust automotive seals, the journey from concept to creation is one of precision, expertise, and a deep understanding of material science.

H2: What is Custom Precision Molding?

Custom precision molding is a sophisticated manufacturing process that produces parts by injecting molten material, such as liquid silicone rubber (LSR), into a uniquely designed mold cavity under high pressure. Unlike standard molding, this technique is defined by its ability to create components with extremely tight tolerances, complex geometries, and superior repeatability. The process begins with a collaborative design phase and moves through meticulous tooling, prototyping, and production, ensuring every single part perfectly matches the client's specifications.

H2: The Core Advantage: Why Customization Matters

Standard components can't meet the specialized needs of advanced applications. Customization allows for complete design freedom, enabling the creation of parts that integrate perfectly into a larger assembly, optimize performance, and solve unique challenges. Key benefits include:

- Perfect Fit and Function: Parts are designed to exact specifications, eliminating inefficiencies and potential failure points.

- Material Optimization: The ideal grade of silicone, with specific properties like durometer (hardness), chemical resistance, or biocompatibility, can be selected.

- Consolidation of Parts: Multiple components can often be redesigned into a single, complex part, reducing assembly time and cost.

- Brand Differentiation: Unique designs and features can set a product apart in a competitive market.

H2: Silicone Rubber: The Ideal Material for Precision Applications

Silicone rubber stands out as a premier material for custom molding due to its exceptional range of properties. Its flexibility, stability across extreme temperatures, and inherent purity make it indispensable in critical sectors. Unlike many thermoplastics, silicone maintains its integrity in harsh environments, making it a reliable choice for long-term applications.

H2: Advanced Molding Techniques for Silicone Products

Achieving true precision requires more than just a good mold. We employ a range of advanced techniques to push the boundaries of what's possible:

- Liquid Silicone Rubber (LSR) Injection Molding: This is the cornerstone of modern silicone molding. LSR is a two-part platinum-cured system that is pumped into a heated mold. The process is highly automated, allowing for fast cycle times, minimal material waste, and exceptional part consistency, making it ideal for high-volume production.

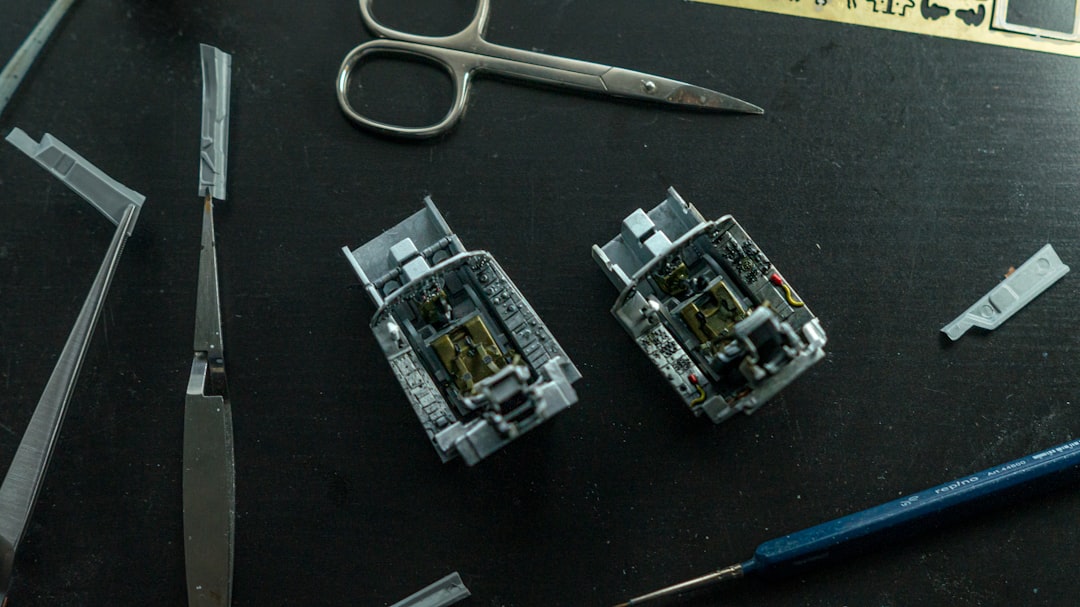

- Micro-Molding: For the electronics and medical industries, component size is often microscopic. Micro-molding specializes in producing incredibly small, intricate silicone parts with flawless detail and precision, often weighing less than a single gram.

- Overmolding & Insert Molding: These techniques allow for the combination of materials to create a single, integrated component.

- Overmolding: Molding silicone rubber over a rigid substrate (like plastic or metal) to add a soft-touch grip, a flexible seal, or impact protection.

- Insert Molding: Placing a component (e.g., a metal thread or an electronic sensor) into the mold cavity before injecting the silicone, permanently encapsulating it.

H2: The Blueprint for Precision: Design and Engineering

Every successful project starts with a robust design. Our engineering team collaborates closely with clients from the very beginning. Using advanced CAD and simulation software, we analyze part design for moldability (DFM), anticipating potential challenges like air traps, sink marks, or inconsistent wall thickness. This proactive approach ensures a seamless transition from a digital model to a physical, high-quality part and accelerates time-to-market.

H2: Tooling: The Heart of the Precision Molding Process

The mold, or tooling, is arguably the most critical element in precision injection molding. It is not merely a cavity; it's a complex piece of engineering built from high-strength steel to withstand repeated high-pressure injection cycles. Key aspects of precision tooling include:

- Multi-Cavity Molds: For high-volume production, molds with multiple cavities produce several parts in a single cycle, dramatically increasing efficiency.

- Advanced Cooling Channels: Conformal cooling channels that follow the part's geometry ensure uniform temperature distribution, reducing cycle times and preventing defects like warpage.

- Runner Systems: Sophisticated hot runner systems maintain precise temperature control of the LSR until it enters the cavity, ensuring optimal flow and reducing material waste.

H2: Material Selection: Tailoring Properties to the Application

Not all silicone is created equal. The selection of the right material is critical to a part's success. We work with a wide range of silicone formulations and other elastomers to meet specific performance requirements.

| Property Requirement | Recommended Silicone Grade/Type | Common Applications |

|---|---|---|

| High-Temperature Resistance | Phenyl-Based (PVMQ) Silicone | Aerospace seals, automotive gaskets |

| Biocompatibility & Purity | Medical-Grade, Platinum-Cured LSR | Surgical tools, respiratory masks, implants |

| Chemical & Oil Resistance | Fluorosilicone (FVMQ) | Fuel systems, industrial seals |

| Extreme Flexibility | Low Durometer Silicone | Wearable electronics, soft-touch buttons |

| Electrical Insulation | High Dielectric Strength Silicone | Electronic connectors, wire insulation |

H2: Quality Assurance: The Commitment to Zero-Defect Production

Precision molding demands a rigorous commitment to quality at every stage. A single micron of deviation can mean the difference between success and failure. Our quality assurance protocol integrates:

- Real-Time Process Monitoring: Sensors within the molding machine track key parameters like injection pressure, temperature, and cycle time, allowing for instant adjustments.

- Automated Optical Inspection: High-resolution cameras scan each part to verify dimensional accuracy and check for surface imperfections, ensuring 100% compliance.

- Stringent Testing: We conduct functional tests, material property verification, and lifecycle analysis to guarantee that every component will perform flawlessly in its intended environment.

H2: Applications Across Industries

Custom precision molded silicone components are vital in numerous sectors:

- Medical & Healthcare: From biocompatible seals and O-rings for diagnostic equipment to complex parts for surgical devices and drug delivery systems.

- Automotive: Creating durable gaskets, seals, and vibration-dampening components that withstand extreme temperatures and fluids.

- Electronics: Manufacturing protective casings, keypad buttons, and miniature insulators for consumer and industrial electronics.

- Consumer Goods: Producing everything from custom bakeware and kitchen utensils to ergonomic grips for tools and appliances.

H2: Partnering for Success in Custom Silicone Manufacturing

Choosing the right manufacturing partner is about more than just capabilities; it's about finding a team that functions as an extension of your own. A true partner offers collaborative design support, deep material expertise, and an unwavering commitment to quality. They invest in the latest technology not just to make parts, but to engineer solutions that drive innovation and deliver a competitive advantage.

H2: Conclusion: The Future is Custom and Precise

As technology advances and product requirements become more stringent, the role of custom precision molding will only grow. For silicone rubber products, this process unlocks a level of performance, reliability, and design freedom that is simply unattainable with standard methods. By embracing customization and investing in the expertise required for true precision, manufacturers can deliver components that not only meet a specification sheet but also provide lasting value and drive industry-wide progress.