Benefits of Silicone Overmolding on Metal for Consumer Electronics

- Share

- publisher

- siliconeplus

- Issue Time

- Oct 28,2025

Summary

xplore how silicone overmolding on metal enhances durability, safety, heat management, and design in consumer electronics.

Introduction:

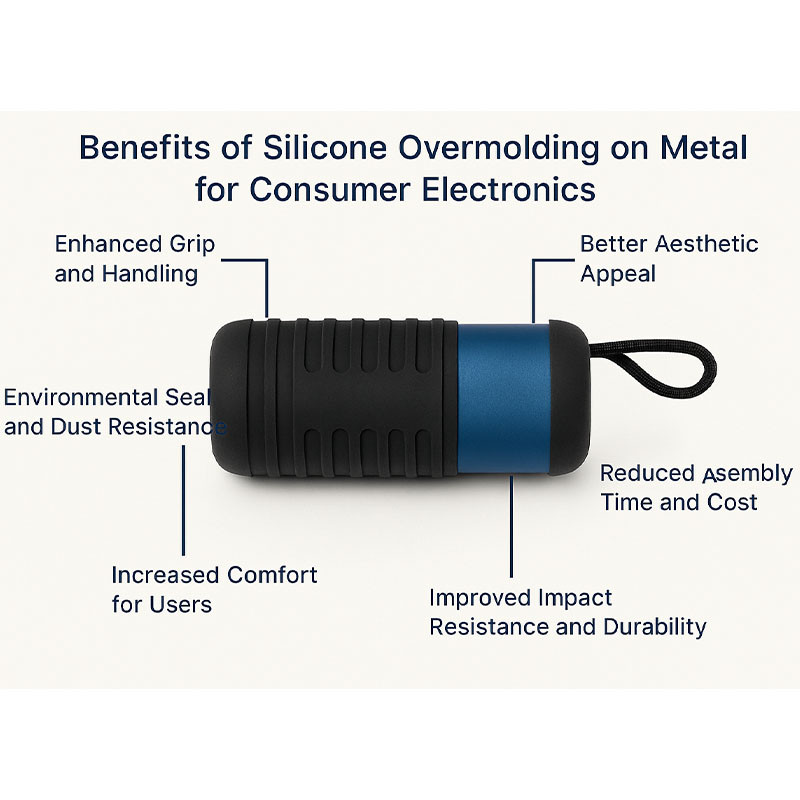

In the rapidly evolving landscape of consumer electronics, manufacturers face persistent challenges to improve product durability, performance, and user safety. Silicone overmolding on metal components has emerged as a revolutionary solution, offering an extensive range of benefits that surpass traditional manufacturing methods. This comprehensive exploration delves into the remarkable advantages of integrating silicone overmolding into metal-based consumer electronic devices, highlighting how this process enhances product lifespan, safety, aesthetics, and functional performance.

Introduction to Silicone Overmolding on Metal Components

Silicone overmolding involves the application of a flexible, durable silicone elastomer onto metal substrates such as aluminum, copper, or stainless steel. This process creates a composite structure that combines the strength and thermal conductivity of metal with the flexibility, insulation properties, and chemical resistance of silicone. The result is a high-performance, resilient, and aesthetically appealing component suitable for the demanding environment of consumer electronics.

Enhanced Durability and Mechanical Protection

Superior Shock Absorption and Impact Resistance

Silicone overmolded metal components excel in absorbing mechanical shocks and vibrations, significantly reducing the risk of damage during daily use or accidental drops. The elastic nature of silicone acts as a buffer, safeguarding delicate electronic parts embedded within or attached to metal structures. This shock mitigation extends the lifetime of devices, especially those subjected to frequent handling, such as smartphones, wearable gadgets, and portable devices.

Corrosion and Chemical Resistance

Silicone coatings provide an excellent barrier against moisture, dust, and corrosive substances, which are common threats in various environments. When overmolded onto metal surfaces, the silicone layer prevents oxidation and corrosion, maintaining the integrity and appearance of the component over extended periods. This chemical resistance is particularly advantageous in outdoor electronics and industrial consumer devices exposed to harsh conditions.

Thermal Management and Heat Dissipation

Improved Heat Distribution

Metal components are renowned for their thermal conductivity, essential for dissipating heat generated by electronic circuits. When combined with silicone overmolding, this heat transfer capability is preserved and even optimized. Silicone's thermal stability ensures that heat is evenly spread, preventing hot spots that could degrade electronic performance or cause failure.

Protection Against Thermal Fluctuations

Silicone's high-temperature tolerance (up to 200°C or higher) enables it to withstand thermal cycling without cracking or losing adhesion. This thermal resilience ensures that metal-silicone composites maintain their structural integrity in environments with extreme temperature variations, such as outdoor wearables or portable gadgets used in diverse climates.

Electrical Insulation and Safety Enhancement

Superior Insulating Properties

Silicone overmolding provides excellent electrical insulation, preventing short circuits and electrical leakage. This property is critical in consumer electronics where user safety and device reliability are paramount. The non-conductive nature of silicone ensures that metal parts are effectively insulated from electrical currents, reducing shock hazards and device malfunctions.

Enhanced Safety Standards Compliance

Devices with silicone overmolded metal components are better equipped to meet stringent safety standards such as UL, CE, and FCC certifications. The robust insulation and protective barrier provided by silicone contribute to compliance, instilling consumer confidence and brand reputation.

Aesthetic and Tactile Advantages

Customizable Surface Finishes

Silicone overmolding allows for highly customizable surface textures and colors, enabling brand differentiation and consumer appeal. The soft, matte finish of silicone provides a premium feel and improved grip, enhancing user experience. Additionally, the variety of colors and patterns can be integrated into the overmold to match product design specifications.

Seamless Integration and Ergonomics

The flexibility of silicone enables the creation of seamless, ergonomic designs that conform to device contours. This results in comfortable handheld devices and aesthetic consistency, elevating the overall product quality.

Environmental Resistance and Longevity

UV and Weather Resistance

Silicone coatings resist UV radiation, ozone, and weathering, making overmolded devices suitable for outdoor applications. This resistance ensures color retention, material stability, and performance consistency over years of exposure to sunlight and moisture.

Extended Product Lifespan

The combined mechanical robustness, chemical resistance, and thermal stability of silicone overmolding significantly extend the service life of consumer electronic products. This durability reduces warranty costs, returns, and environmental impact due to less frequent replacements.

Manufacturing Efficiency and Cost-Effectiveness

Streamlined Production Processes

Silicone overmolding can be integrated into automated manufacturing lines, allowing for rapid, high-volume production. The process is compatible with various metal substrates and can be customized to suit specific design requirements, reducing assembly time and costs.

Reduced Post-Processing and Assembly

The integrated overmolding process minimizes the need for additional protective layers, adhesives, or fasteners. This simplification leads to fewer manufacturing steps, lower labor costs, and fewer potential points of failure.

Case Studies: Silicone Overmolding in Consumer Electronics

| Product Type | Application | Key Benefits Achieved |

Smartphones | Protective casing and buttons | Shock absorption, improved grip, water resistance |

Straps and housing | Flexibility, durability, thermal management | |

| Bluetooth Speakers | Housing and controls | Weather resistance, aesthetic customization |

| Power Banks | Outer shell | Chemical resistance, impact protection |

| Wireless Earbuds | Charging case | Seamless design, ergonomic feel |

Conclusion: The Future of Consumer Electronics with Silicone Overmolding

The integration of silicone overmolding on metal components marks a paradigm shift in consumer electronics manufacturing. Its multi-faceted advantages—from enhanced durability and thermal management to improved safety and aesthetic appeal—position it as an indispensable technology for innovative device design. As consumer expectations continue to rise for robust, reliable, and stylish products, silicone overmolding will undoubtedly play a central role in shaping the future of electronic devices.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883